Hello,

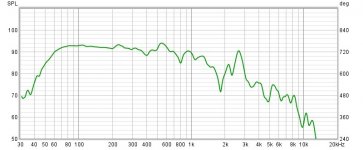

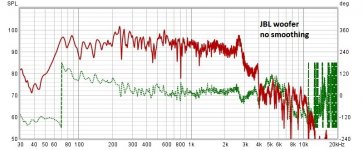

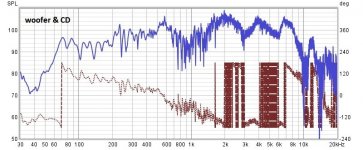

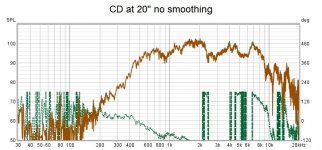

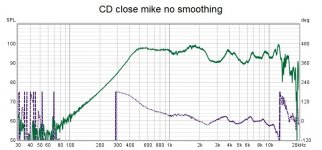

I brought 2 used PA cabs Sr-4733x for cheap would like to build 2 ways x-over. The CD is not original. The woofer is from JBL don't know if it's original . I don't trust my measurements as it doesn't sound dull i.e. missing the high . I did the individual drivers in DAT. I eventually will try to get the accurate measurements in REW.

I brought 2 used PA cabs Sr-4733x for cheap would like to build 2 ways x-over. The CD is not original. The woofer is from JBL don't know if it's original . I don't trust my measurements as it doesn't sound dull i.e. missing the high . I did the individual drivers in DAT. I eventually will try to get the accurate measurements in REW.

Attachments

-

IMG_4381.jpg41.3 KB · Views: 123

IMG_4381.jpg41.3 KB · Views: 123 -

IMG_4382.jpg38.7 KB · Views: 145

IMG_4382.jpg38.7 KB · Views: 145 -

IMG_4375.jpg54.1 KB · Views: 118

IMG_4375.jpg54.1 KB · Views: 118 -

IMG_4376.jpg39.2 KB · Views: 126

IMG_4376.jpg39.2 KB · Views: 126 -

IMG_4377.jpg35.6 KB · Views: 112

IMG_4377.jpg35.6 KB · Views: 112 -

IMG_4379.jpg48.9 KB · Views: 128

IMG_4379.jpg48.9 KB · Views: 128 -

IMG_4365.jpg49.1 KB · Views: 128

IMG_4365.jpg49.1 KB · Views: 128 -

IMG_4366.jpg53.8 KB · Views: 131

IMG_4366.jpg53.8 KB · Views: 131 -

IMG_4367.jpg45.5 KB · Views: 122

IMG_4367.jpg45.5 KB · Views: 122

Last edited:

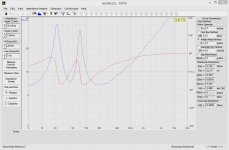

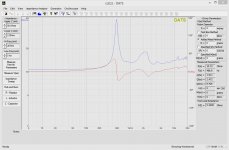

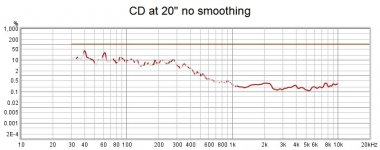

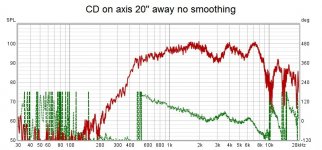

Try an on-axis capture taken at 20" out ( and then also look at the distortion tab in REW ).

The diaphragm might need adjusting to give a more linear output.

🙂

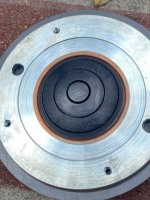

the CD looks clean no visible burn mark or burp. Its 16ohm label so must be after market. Next step to re-align assemble horn then re-test. Any idea where to buy the original diagram for the CD? Searching come empty. Thanks

Attachments

Original Diaphragm ??

I suspect that a search for new OEM diaphragms will be futile ( the companies web-site is long gone ).

I think your drivers were "Private Label" knock-offs of something like the ancient B&C de700tn ( with some important differences ).

- They could have been made by any one of number of asian manufacturers ( even P-Audio in Thailand ).

If you can't get fairly linear response from these drivers ( after re-setting the diaphragms ) then it's time to start looking for replacement drivers having a 1.5" exit.

B&C made the ferrite magnet ( 1.5" exit ) de700tn. You might find a pair of those for cheap if your patient.

- I see that Parts Express still sell replacement diaphragms for that particular driver. LINK to part at P.E.

🙂

I suspect that a search for new OEM diaphragms will be futile ( the companies web-site is long gone ).

I think your drivers were "Private Label" knock-offs of something like the ancient B&C de700tn ( with some important differences ).

- They could have been made by any one of number of asian manufacturers ( even P-Audio in Thailand ).

If you can't get fairly linear response from these drivers ( after re-setting the diaphragms ) then it's time to start looking for replacement drivers having a 1.5" exit.

B&C made the ferrite magnet ( 1.5" exit ) de700tn. You might find a pair of those for cheap if your patient.

- I see that Parts Express still sell replacement diaphragms for that particular driver. LINK to part at P.E.

🙂

Last edited:

Sorry for the misspelling.

Yes I could buy a new B&C diaphragm.

But could it be the horn that caused it? I took a couple more while at it.

Yes I could buy a new B&C diaphragm.

But could it be the horn that caused it? I took a couple more while at it.

Attachments

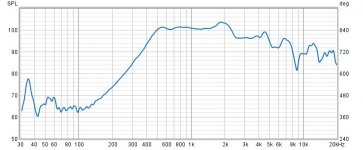

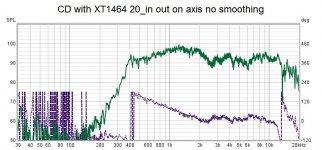

Sure, ( the un-even response might be caused by the funky looking exit area of your horn > which actually looks like a 2" exit driver would do better ).

The only way to test that theory is to buy a horn that's known to have smooth loading ( such as 18Sound XT1464 or FaitalPro LTH142 ).

- They are unfortunately 1.4" entry ( not 1.5" ) .

JBL has some 1.5" entry horns ( just stick with those that have smooth walls >> no bumps or knuckles >> iow; a pure bi-radial ).

🙂

The original driver is the JBL 2447:

https://jblpro.com/en/product_documents/2447-pdf

1.5" exit, despite the weird throat. The response also seems to drop off like your compresion driver begining at 7kHz (although with smoother response):

In any of the horn measurments are there passive components performing equalisation to compensate for the constant directivity horn roll off?

https://jblpro.com/en/product_documents/2447-pdf

1.5" exit, despite the weird throat. The response also seems to drop off like your compresion driver begining at 7kHz (although with smoother response):

In any of the horn measurments are there passive components performing equalisation to compensate for the constant directivity horn roll off?

That WG throat area interface sure looks horrible as does the WG throat transition (or lack thereof).

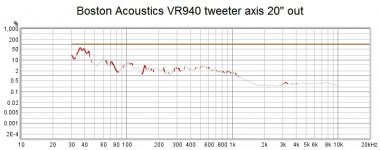

I agree, a bi-radial, tractrix or expo WG would be better in most cases but that compression driver is weird. It does appear to have a copper demodulation ring in the VC gap, so that sort of makes me think its a knock off of a B&C or Lavoce. The diaphragm sure looks suspect as being a generic, but i don't see any tell tale signs of VC misalignment based on impedance response.

I agree, a bi-radial, tractrix or expo WG would be better in most cases but that compression driver is weird. It does appear to have a copper demodulation ring in the VC gap, so that sort of makes me think its a knock off of a B&C or Lavoce. The diaphragm sure looks suspect as being a generic, but i don't see any tell tale signs of VC misalignment based on impedance response.

The WG throat transition can ( no-doubt ) be improved with a bit of plumbers putty applied to get rid of all the sharp transitions ( dis-continuities ) that one sees at the horns' entrance.

Some years back I did the same to one horn ( of a pair ) that I bought from ZXPC .

Here's what (even a crap ) putty application can achieve ( it actually achieved a very usable response ) .

This is raw response from 20" out.

🙂

Some years back I did the same to one horn ( of a pair ) that I bought from ZXPC .

Here's what (even a crap ) putty application can achieve ( it actually achieved a very usable response ) .

This is raw response from 20" out.

🙂

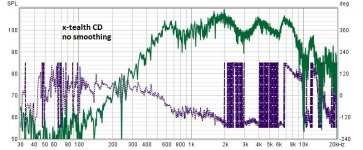

The XT1464//X-Tealth combo response looks a lot better.

The entrance to that ( unknown ) horn looks larger than 1.5" ( is it 2" ?? ).

If it's ( 2" ) then you need to adapt your horn drivers 1.5" exit to the larger horn entrance ( with something like the P-Audio PC-5038 ).

A mismatch like that ( 1.5" driver exit to 2" horn entry ) will certainly cause the problems seen in your initial response pics.

I use ( actually ) GB Duct Seal for smoothing horn transition discontinuities ( available at Home Depot ).

🙂

The entrance to that ( unknown ) horn looks larger than 1.5" ( is it 2" ?? ).

If it's ( 2" ) then you need to adapt your horn drivers 1.5" exit to the larger horn entrance ( with something like the P-Audio PC-5038 ).

A mismatch like that ( 1.5" driver exit to 2" horn entry ) will certainly cause the problems seen in your initial response pics.

I use ( actually ) GB Duct Seal for smoothing horn transition discontinuities ( available at Home Depot ).

🙂

Last edited:

Make sure your driver actually has a 1.5" exit ( rather than the more common 1.4" exit ).

The Eminence HA14-2 adapter is very good ( and a lot cheaper than the P-Audio ) .

The Eminence HA14-2 adapter is very good ( and a lot cheaper than the P-Audio ) .

- Home

- Loudspeakers

- Multi-Way

- help creating x-over for 15" PA cab