Pico,

What a kind offer. And thanks for your support too.

I would not be prepared to attempt that task without a pretty good pillar drill and top class drills and taps. The cost of such kit for making, in my case, a couple of of amps would be sheer waste of money...and the risk level of a tool breaking in the alloy would be reasonably high!

But thanks again Pico.🙂

What a kind offer. And thanks for your support too.

I would not be prepared to attempt that task without a pretty good pillar drill and top class drills and taps. The cost of such kit for making, in my case, a couple of of amps would be sheer waste of money...and the risk level of a tool breaking in the alloy would be reasonably high!

But thanks again Pico.🙂

Case costs

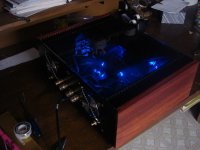

My F-5 case was built from three pieces of 1/8" aluminum plate/sheet for the bottom, front and rear. The left and right sides made use of drilled and tapped holes in the Conrad heatsinks. The top was bronze tinted plexiglass (which I had handy in my scrap bin). The aluminum plate was left over from some of my car building projects, so my cost was basically the heatsinks and Allen head button screws.

I got the front engraved and anodized. The two "cheeks" on the front panel were also scrap 1/2" aluminum I milled down.

All told, my cost was the two heatsinks and my labor. (I'd rack that up as "a labor of love" though....)

My F-5 case was built from three pieces of 1/8" aluminum plate/sheet for the bottom, front and rear. The left and right sides made use of drilled and tapped holes in the Conrad heatsinks. The top was bronze tinted plexiglass (which I had handy in my scrap bin). The aluminum plate was left over from some of my car building projects, so my cost was basically the heatsinks and Allen head button screws.

I got the front engraved and anodized. The two "cheeks" on the front panel were also scrap 1/2" aluminum I milled down.

All told, my cost was the two heatsinks and my labor. (I'd rack that up as "a labor of love" though....)

Attachments

Up and down like a yoyo !Chilly here today!

Hope you get on top of your health and that it is not too debilitating.

A while since we met up.

Thanks Andrew.....and snow forecast for tomorrow!

Carol is away skiing next week...so, if convenient, send me a PM; post code (for sat nav) with your tel.no. and I will pop over.

Health holding up....except heavy/akward lifting is now a thing of the past [hence this thread!].

Carol is away skiing next week...so, if convenient, send me a PM; post code (for sat nav) with your tel.no. and I will pop over.

Health holding up....except heavy/akward lifting is now a thing of the past [hence this thread!].

My F-5 case was built from three pieces of 1/8" aluminum plate/sheet for the bottom, front and rear. The left and right sides made use of drilled and tapped holes in the Conrad heatsinks. The top was bronze tinted plexiglass (which I had handy in my scrap bin). The aluminum plate was left over from some of my car building projects, so my cost was basically the heatsinks and Allen head button screws.

I got the front engraved and anodized. The two "cheeks" on the front panel were also scrap 1/2" aluminum I milled down.

All told, my cost was the two heatsinks and my labor. (I'd rack that up as "a labor of love" though....)

Fantastic looking.

It is good to see you are not afraid of fans as some are. With fans you can bias that sucker up! I enjoy seeing the artistry of other members with their case builds. Truly diy to another level. I will agree most will want to buy a ready to use case and for most the cost savings of building yourself will not be that great if any. I have one store case and one I built myself but it looks nothing like this. More of a Frankenstein looking case but it works. The electronics do not know the difference.

Bare, to make things "easier" on myself, I had customers cuts made to size. It adds a few bucks to the cost.

With the correct blade, it can be cut on a table saw as well. I sure didnt do it, but the member who supplied the sheet material did. As to the ventilation, having no means to do it my self short of drilling a bunch of messy holes, I elected to space the top and bottom covers about a 1/4 inch or so.

Russellc

Having seen piccies of your Box.. I was impressed by the ingenuity /effectiveness of the spaced panels.

Enough motivation try to emulate the technique 😱

Still remains to be seen if .. I can make it work tho.

Enough motivation try to emulate the technique 😱

Still remains to be seen if .. I can make it work tho.

Fantastic looking.

....... I have one store case and one I built myself but it looks nothing like this. More of a Frankenstein looking case but it works. The electronics do not know the difference.

I believe classical electromagnetic theory and poynting vector analysis have empirically shown electrons flow 43.6% faster in a well designed and constructed chassis......(!) 😀

There has been a rumour that the Store may be able to offer drilled heat-sinks for 4U & 5U cases. This should, if it happens not only increase the options for builders but also increase the Store's revenue figures.

If this really interests you please post a response so that some feedback gets to those who can make a stocking decision.

I'm back now 🙂 These will be available within 4 days, and I absolutely agree that they will increase the options for builders. I certainly don't want people to have to buy a whole chassis just to get the heatsinks. The whole point of creating the UMS standard was to make it easier for everyone to DIY 🙂

Sorry for my poor attendance, as mentioned in the other chassis thread. Expect a lot more action very shortly...

Delighted - and thank you Jason. I expect to be one of your first customers!

And also I hope that you soon settle in to your new base and home.

Where have you moved to?

And also I hope that you soon settle in to your new base and home.

Where have you moved to?

Bco , isn't better to ship directly from funny 'Talians , instead across big splash?

you can always donate difference to DiyA , if you eager to support site

you can always donate difference to DiyA , if you eager to support site

we can make some cultural exchange , of things we have most

ya send me pair of 'Roos and I can send you few containers of depletion uranium radiation

(ya know for some secret and new continent , non-populated, where we can deport all politicians of the world ?)

ya send me pair of 'Roos and I can send you few containers of depletion uranium radiation

(ya know for some secret and new continent , non-populated, where we can deport all politicians of the world ?)

@ZM

UK buyers have the goodies shipped direct from Italy, net of UK duties etc. 😎 (I hope that DIYa make a few % too)

You miss your coffee again this morning? 😉

UK buyers have the goodies shipped direct from Italy, net of UK duties etc. 😎 (I hope that DIYa make a few % too)

You miss your coffee again this morning? 😉

Last edited:

we can make some cultural exchange , of things we have most

ya send me pair of 'Roos and I can send you few containers of depletion uranium radiation

(ya know for some secret and new continent , non-populated, where we can deport all politicians of the world ?)

We don't need no depleted uranium we have the biggest uranium ore deposits in the world, 31% of world total.

Maybe we are lucky after all. 😀

Happy to send you any Australian souvenirs.

Plenty of land here to hide and torture unwanted politicians "wolf creek style"

...............

Plenty of land here to hide and torture unwanted politicians "wolf creek style"

If you like that kind of fun we could send you a ship load of them.

Regular and UMS pre-drilled heatsinks along with chassis mounting brackets for 300 and 400 deep Dissipante / Deluxe chassis are now available for purchase separately in the store:

- Status

- Not open for further replies.

- Home

- Amplifiers

- Pass Labs

- Heat-Sinks