I suck at this.

I've tried a multiplicity of different types of paper, modified a laminator to heat the board and paper, bought a iron specifically to do this with... and I've never had a good result.

🙂 and I just keep feeling like I'm a diy fail. Anyone else have this moment?

I've tried a multiplicity of different types of paper, modified a laminator to heat the board and paper, bought a iron specifically to do this with... and I've never had a good result.

🙂 and I just keep feeling like I'm a diy fail. Anyone else have this moment?

one thing I noticed was that printing with fresh toner powder/cartridge gave the best results compared to old toner powder/cartridge which did not adhere to the pcb.

I had good results with different makes of glossy photopaper.

I had good results with different makes of glossy photopaper.

I had excellent results using inkjet glossy photo paper. Made all traces and pads thicker though. Used an iron and another sheet of paper between iron and the photo paper. The copper must be well cleaned and brushed with the green rough side of a dish washing sponge.

I rarely go to prototype pcb's.

Only if some part of the circuit is not fully known.

I get my pcb's made in China.

They cost about 1/3 of the price they do in the UK.

2 weeks from order to pcb's through my letterbox.

I get excellent pcb's that look very professional.

I do have to order minimum of 5 pcb's though.

Only if some part of the circuit is not fully known.

I get my pcb's made in China.

They cost about 1/3 of the price they do in the UK.

2 weeks from order to pcb's through my letterbox.

I get excellent pcb's that look very professional.

I do have to order minimum of 5 pcb's though.

Yup, PCB fab houses for me going forward.

Yup, I think that's the way to go. I don't have enough time as it is so I might just give up on toner transfer...

Cheers for he advice as well folks. This was the last attempt for me. I used fancy paper and did it all in best possible practice and to no avail. I'm happy to wait and get it done properly by a Chinese fab I think!

Yup, I think that's the way to go. I don't have enough time as it is so I might just give up on toner transfer...

Cheers for he advice as well folks. This was the last attempt for me. I used fancy paper and did it all in best possible practice and to no avail. I'm happy to wait and get it done properly by a Chinese fab I think!

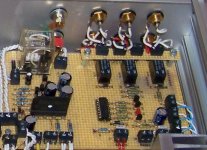

I don't do much pcb manufacturing but when I do I prefer

to wire all the components with bare wire. I print the parts

and traces layout on both of the sides of pertinax predrilled

board and follow the paths.

An excellent method. Hard to argue that it would be more time consuming than creating a proto pcb. It's been a long time that I've heard the word pertinax. 🙂

Lovely work! I am absolutely full of admiration for folks who can generate that kind of work from that process. I've tried the same, but inevitably end up 'planning' the build by drawing it up in eagle... and then wondering why I don't just make a PCB from that art 🙂

I've also tried doing the art, and then laying it on the board and drilling the holes, and then drawing by hand between them... the current project is a bit ...large and I want to do two of em, soon won't try this this time. 🙂

I've also tried doing the art, and then laying it on the board and drilling the holes, and then drawing by hand between them... the current project is a bit ...large and I want to do two of em, soon won't try this this time. 🙂

I have excellent results making my own using pre-sensitised photo-resist boards and light exposure through laser printed transparencies.

I regularly use 0.5mm pitch SMD chips and have gone down to 0.4mm when necessary (by accident -.-).

I regularly use 0.5mm pitch SMD chips and have gone down to 0.4mm when necessary (by accident -.-).

Member

Joined 2009

Paid Member

I had a lotta trouble until I found that I needed to

A) use glossy magazine paper

B) use a suitable laser printer ( my home Brother laser dosn't work but the printer at work s great)

C) don't iron the paper onto the copper, put the paper face up and the copper board on top face down and then iron through the board with iron on hot, press firmly and slowly move iron around, do this for about 30s. If you get it too hot the toner smudges, in which case ease off a bit.

A) use glossy magazine paper

B) use a suitable laser printer ( my home Brother laser dosn't work but the printer at work s great)

C) don't iron the paper onto the copper, put the paper face up and the copper board on top face down and then iron through the board with iron on hot, press firmly and slowly move iron around, do this for about 30s. If you get it too hot the toner smudges, in which case ease off a bit.

Thanks guys! I'd like to point out that my guiding idea to make

boards this way wasn't a belief that somehow wire is better than

professional executed stuff, but my hesitance to spend extra cash

on accessories to complete it in a traditional fashion. Certainly I won't

be pulling this kind of a stunt on a frequent basis.

boards this way wasn't a belief that somehow wire is better than

professional executed stuff, but my hesitance to spend extra cash

on accessories to complete it in a traditional fashion. Certainly I won't

be pulling this kind of a stunt on a frequent basis.

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- :headbash: So I suck at toner transfer pcbs