The term came up and someone was posting information that I found questionable.

Terms used to describe the intensity of the vacuous space within a vacuum tube’s glass envelope. A hard vacuum denotes a more complete vacuum is created in the tube manufacturing process. Hard vacuum tubes – like the 6L6 and 6550 – have a higher saturation threshold and therefore distort less easily then soft vacuum tubes. Soft vacuum tubes – such as the EL34 or 6CA7 – have a less intense vacuum (sometimes called a gassy vacuum), saturate more easily and therefore break up [distort] more quickly. - Sweetwater

"What is tube "hardness"?"

First time I heard about soft and hard tubes. I looked it up and it sounded questionable to me."The tube "hardness" or "softness" - as you justifiably name itDijimiWrey - is narrowly associated with the degree of vacuum in the tube itself.

Tight vacuum tubes sound "harder" when clipped, have more headroom and attack, less compression, can afford more plate dissipation, and last longer because they hold their tolerance tighter over time. This is often the prerogative of military or industrial tubes if they have been suitably stored over time.

Soft vacuum tubes sound "softer" when clipped, less headroom and beefy punch, more compression and sensivity, but they widhstand less plate dissipation (beware red plating) and have a shorter life duration because their tolerances degrade faster over time.

In the early days of Radio, it was well-known that lower vacuum tubes were better for receiver detection stages (where more sensivity was needed) and higher vacuum tubes were prefered for RF amplification stage (where gain stability was required)."

So I am questioning the most knowledgeable bunch of tube geeks (if I may say so) that I know of. So is the concept true? Or is it somehow mistaking tube geometry somehow? Inquiring minds, you know how it goes.I remember reading an Aspen Pittman article on how the vacuum within the output tube = degree of distortion. And thus the myth began...

I think a definition of vacuum is needed.

Tubes have a getter for some gas chemicals but I doubt it would react with all gas (chemically). So it could be feasible over thins.

Pass devices (6as7 and 6550?) I could postulate need a better vaccum to prevent the high current from causing a larger ionisation?

Gas’s molecules would interrupt and cause imprecise operation of the tube unless the tube was designed to create audio distortion on purpose.

Tubes have a getter for some gas chemicals but I doubt it would react with all gas (chemically). So it could be feasible over thins.

Pass devices (6as7 and 6550?) I could postulate need a better vaccum to prevent the high current from causing a larger ionisation?

Gas’s molecules would interrupt and cause imprecise operation of the tube unless the tube was designed to create audio distortion on purpose.

One of the suppliers of vacuum tubes to the guitar amp crowd started rating their relabeled imported tubes with a number on a scale of 1 to 10. They called this number "hardness", and it referred to the "tone" quality of the sound it produced. 1 produced a soft tone that eased gently into distortion. 10 had a sharp edge that went from clean to nasty. How these numbers were generated is anybody's guess. This was at least 10 years ago, and I can't remember who it was.

The concept of a hard VS soft vacuum has been known for decades. If measured, grid current is the most reliable indicator.

The concept of a hard VS soft vacuum has been known for decades. If measured, grid current is the most reliable indicator.

As far as I know, soft tubes/valves refers to the tubes used in the first decade or two of the twentieth century. Most tubes didn't have getters yet and the vacuum pumps were not that good. As a result, you wouldn't need a grid leak resistor because the tube leaked enough to bias its own grid.

According to Timeline @ The Valve Museum , the first hard vacuum triodes were made in France in 1915.

According to Timeline @ The Valve Museum , the first hard vacuum triodes were made in France in 1915.

I would expect the softness of the tube tone to depend on the sharpness of the plate curve knees, not much to do with vacuum level.

i think there is still a distinction with later (than 1915) tubes as to vacuum "hardness". HV transmitting tubes need to remove gases to a better level to avoid high energy ion bombardment of the cathode. De-gassing the tube takes longer then, so becomes more expensive to produce. Gettering does remove most of the residual gas for tubes, but will not remove Argon, which makes up 1% of the atmosphere.

So either a very long evacuation time (vacuum doesn't travel well thru tiny evacuation glass tubing), or back filling with N2 followed by 2nd evacuation is required for hard vacuum transmitting tubes. These tubes usually get a thorough high temp (glowing metals) bake-out to remove gases in the metals during evacuation, and Pyrex or Quartz envelopes. Likely special electrode feed-thru seals too. I would seriously doubt any audio or receiving/TV type tubes get this special treatment. Maybe 6BK4.

Modern high vacuum lab or production (IC's ) systems have to use big 6" diameter or bigger stainless steel tubing to "convey" high vacuum. The residual molecules just bounce around in them off the surfaces, and don't like going around corners in the tubing well. High vacuum turbo pumps can be 12" or more in diameter. The little glass evacuation lines used for making tubes take a -long- time to remove vacuum level molecules from tubes, so receiving/audio tubes only get evacuated to levels near what a mechanical vacuum piston or scroll pump could do, and depended on gettering to finish the job. So there IS a question whether these tubes are back-filled with N2 first so the gettering will work really well. I've seen quite a few TV power tubes that glow purple when over-loaded, probably argon glow.

i think there is still a distinction with later (than 1915) tubes as to vacuum "hardness". HV transmitting tubes need to remove gases to a better level to avoid high energy ion bombardment of the cathode. De-gassing the tube takes longer then, so becomes more expensive to produce. Gettering does remove most of the residual gas for tubes, but will not remove Argon, which makes up 1% of the atmosphere.

So either a very long evacuation time (vacuum doesn't travel well thru tiny evacuation glass tubing), or back filling with N2 followed by 2nd evacuation is required for hard vacuum transmitting tubes. These tubes usually get a thorough high temp (glowing metals) bake-out to remove gases in the metals during evacuation, and Pyrex or Quartz envelopes. Likely special electrode feed-thru seals too. I would seriously doubt any audio or receiving/TV type tubes get this special treatment. Maybe 6BK4.

Modern high vacuum lab or production (IC's ) systems have to use big 6" diameter or bigger stainless steel tubing to "convey" high vacuum. The residual molecules just bounce around in them off the surfaces, and don't like going around corners in the tubing well. High vacuum turbo pumps can be 12" or more in diameter. The little glass evacuation lines used for making tubes take a -long- time to remove vacuum level molecules from tubes, so receiving/audio tubes only get evacuated to levels near what a mechanical vacuum piston or scroll pump could do, and depended on gettering to finish the job. So there IS a question whether these tubes are back-filled with N2 first so the gettering will work really well. I've seen quite a few TV power tubes that glow purple when over-loaded, probably argon glow.

Last edited:

If you see a tube that has a "getter trough" or a getter holder that is empty, and there is getter on the glass envelope, then chances are that the tube had an RF heater applied to the tube.

That heats the getter trough/holder, and the getter evaporates onto the glass.

That RF heating also heats the tube elements, and there can be outgassing from them due to the heat.

If the vacuum pump is applied at the same time, some of that outgassing goes out of the tube, and so it does not all have to be captured by the getter.

More than once I used to watch the RF heater operation at work.

Before the advent of RF power tubes, RF heaters were not used for vacuum tube production, no matter how bad or good the vacuum was.

Noble gasses are Noble, they can not be captured by common getter matter.

My, how wonderful all those processes are. Those engineers must have been genius.

That heats the getter trough/holder, and the getter evaporates onto the glass.

That RF heating also heats the tube elements, and there can be outgassing from them due to the heat.

If the vacuum pump is applied at the same time, some of that outgassing goes out of the tube, and so it does not all have to be captured by the getter.

More than once I used to watch the RF heater operation at work.

Before the advent of RF power tubes, RF heaters were not used for vacuum tube production, no matter how bad or good the vacuum was.

Noble gasses are Noble, they can not be captured by common getter matter.

My, how wonderful all those processes are. Those engineers must have been genius.

Last edited:

The fine gentleman replied to me with a lot of technical information on tube vacuum but did not respond to the distortion/level of vacuum statement he made earlier. I am glad you all posted. I know there is a world of technical knowledge here that I will never acquire.

If you see a tube that has a "getter trough" or a getter holder that is empty, and there is getter on the glass envelope, then chances are that the tube had an RF heater applied to the tube.

That heats the getter trough/holder, and the getter evaporates onto the glass.

That RF heating also heats the tube elements, and there can be outgassing from them due to the heat.

If the vacuum pump is applied at the same time, some of that outgassing goes out of the tube, and so it does not all have to be captured by the getter.

More than once I used to watch the RF heater operation at work.

Before the advent of RF power tubes, RF heaters were not used for vacuum tube production, no matter how bad or good the vacuum was.

Noble gasses are Noble, they can not be captured by common getter matter.

My, how wonderful all those processes are. Those engineers must have been genius.

You slipped your post in without me looking. For a time I worked in an aerospace company partly to do with vacuum furnaces and induction heating. Lot of cool stuff. I also read some of the technical articles of the early 60's in process control and these guys knew their stuff.

The 4-65A RF tetrode does not even have a getter.

But it does have a hard vacuum

There is a special version of the 4-65A tube (I can not remember the type-name of that Eimac tube).

The plate voltage rating is much higher than the standard 4-65A.

The difference . . . special care is taken to remove all of the burrs on the metal, even the smallest ones.

But it does have a hard vacuum

There is a special version of the 4-65A tube (I can not remember the type-name of that Eimac tube).

The plate voltage rating is much higher than the standard 4-65A.

The difference . . . special care is taken to remove all of the burrs on the metal, even the smallest ones.

The big glass Eimacs, including the 75T - 300T series that work so well for audio, have their gettering on the anodes. They actually *need* to operate with reddish anode color to maintain good vacuum. Eimac does some things we never hear about in receiving valves, like Uranium glass around the seals. Zirconium gettering.

YOS,

Chris

YOS,

Chris

@6A3sUMMER

You're probably thinking of the Eimac 4PR-65A that was rated for pulse service. This was done with several of their tetrods up to 1000 watt plate dissipation. One could use the PR version anywhere the standard would go, but not the reverse.

You're probably thinking of the Eimac 4PR-65A that was rated for pulse service. This was done with several of their tetrods up to 1000 watt plate dissipation. One could use the PR version anywhere the standard would go, but not the reverse.

And that was a poor decision back then because many of the "green glass" Eimacs are gassy today because of leaky seals. Much more then the clear glass. I have decades of experience buying, testing and reselling industrial tubes.Eimac does some things we never hear about in receiving valves, like Uranium glass around the seals.

Is this related to the higher temperatures that Uranium glass sealed valves are presumably subjected to, or to fault in the idea of Uranium glass itself? I wonder because they went to a lot of trouble to do it that way.

Much thanks,

Chris

Much thanks,

Chris

Got a reply.

Not sure what it tells me.

printer2 said: ↑

So just to make sure there is no confusion. I have posted was I do not believe the level of vacuum has the effect you attributed to it. That is all. I looked for technical information to clarify your statements and could not find any. I also asked the good people on diyAudio (quite a knowledgeable bunch) what they thought of your post. They could not confirm what you posted. I make no claims, other than question what you posted.

Too bad for them : they probably never checked this point.

Any old ham radio from the 20-30 era who worked on Armstrong, Schnell or Reinartz regenerative receivers, or Konteschweller / Flewelling super-regeneration receivers knew that vacuum question well. Unfortunately, they are all passed away now...

I have this subject discussed in several of my old books from that era (OK, they are well stored now in my attic, and bring them out would be a hassle).

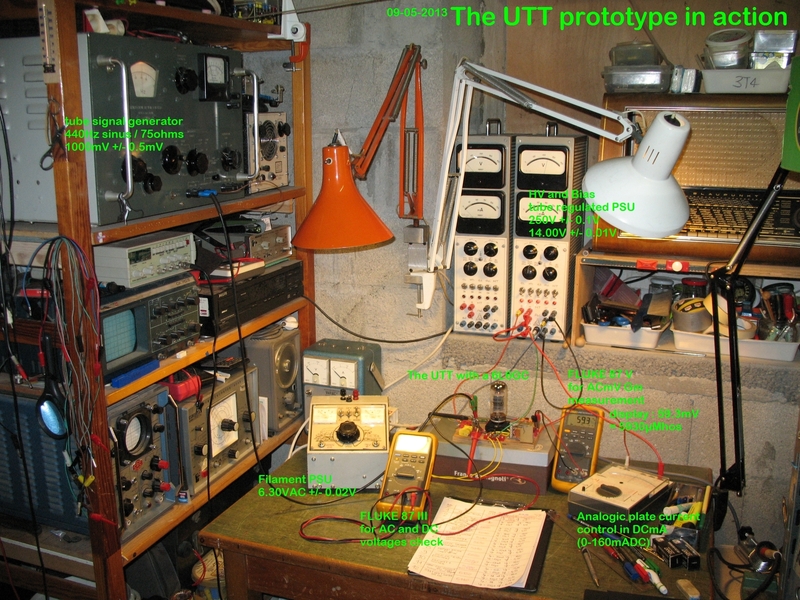

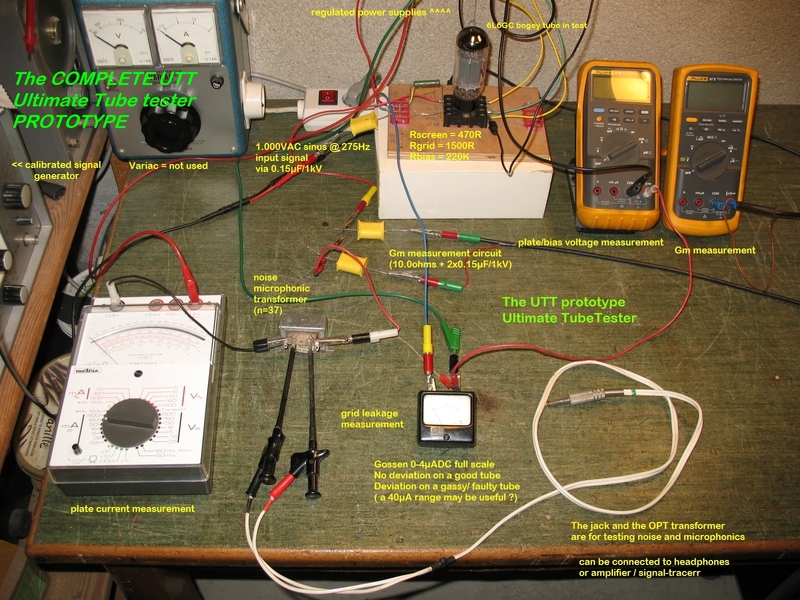

That said, I noticed many times and studied the influence of vacuum degree variations on the tone of guitar amps, and confirmed it by oscilloscope output power monitoring and tube tester checking. That's why I speak about it. Sorry, I do not have pics of all that...

I am one of those who thinks (and have noticed) that the influence of vacuum on the performance of a tube - both in lifespan and about clipping tone - is very important, just like the Guy you and I quoted, by the way.

But it's me, OK ?

-tbln.

Not sure what it tells me.

I don't know just why Eimac began using Uranium glass in the bases of some of their transmitting power tubes. Although they surely had a reason for doing so, I've never been able to find out just why. Uranium glass was used a lot back in the mid 20th century, probably more for looks in things like vases, ashtrays and other home items. I only know that now, 50 plus years later, most Eimac tubes with it will be unusable. And old Eimac tubes are usually more reliable then others. When I was actively dealing with these years ago I threw away too many with green glass bases. It also caused me to not buy them as the risk wasn't worth it, unless they were super cheap. Of course I'd still like to know what their thinking was for using it.Is this related to the higher temperatures that Uranium glass sealed valves are presumably subjected to, or to fault in the idea of Uranium glass itself? I wonder because they went to a lot of trouble to do it that way.

There are tube testers that measure control grid current.

The relative lack of vacuum can cause control grid current.

Does that answer your question?

The relative lack of vacuum can cause control grid current.

Does that answer your question?

leadbelly,

No, I am not mad at you. I apologize.

In my present state of mind, I sometimes consider dropping off this forum.

Too much of the bad side of me gets onto the forum.

Again, I apologize to all.

You are from Calgary. About 1968 or 1969 I went with a college group to Edmonton, end of April, start of March (you know the weather).

We were coming back to the US, between Edmonton and Calgary, late afternoon. A couple of Canadians and their baby had a stalled car. They did not have a coat, water, or food. We managed to get their car started (the spark breaker points leaf metal had come out of the connection (under the distributor cap).

I consider that day to be a miracle.

Thanks for listening.

No, I am not mad at you. I apologize.

In my present state of mind, I sometimes consider dropping off this forum.

Too much of the bad side of me gets onto the forum.

Again, I apologize to all.

You are from Calgary. About 1968 or 1969 I went with a college group to Edmonton, end of April, start of March (you know the weather).

We were coming back to the US, between Edmonton and Calgary, late afternoon. A couple of Canadians and their baby had a stalled car. They did not have a coat, water, or food. We managed to get their car started (the spark breaker points leaf metal had come out of the connection (under the distributor cap).

I consider that day to be a miracle.

Thanks for listening.

- Home

- Amplifiers

- Tubes / Valves

- Hard vs Soft vacuum tubes, distorting more