Happy Christmas and New Year

I have been watching some YouTube videos on valve amp building using the Hammond chassis

I need to buy some tools to cut the holes for the valve bases.

Can any one recommend what I should buy and where please, I am in the UK

Thanks

I have been watching some YouTube videos on valve amp building using the Hammond chassis

I need to buy some tools to cut the holes for the valve bases.

Can any one recommend what I should buy and where please, I am in the UK

Thanks

A guy who builds guitar tube amps recently highly recommended Q-Max punches to me for valves.

Q.Max Sheet Metal Punch - 20mm QMA20M: Amazon.co.uk: DIY & Tools

I've not got them myself but he was very positive about them and they aren't too expensive even over here in Oz!

Q.Max Sheet Metal Punch - 20mm QMA20M: Amazon.co.uk: DIY & Tools

I've not got them myself but he was very positive about them and they aren't too expensive even over here in Oz!

Yes, Q-max are good. You can probably find cheaper ones, but they might not cut such a clean hole and might not last as long.

Careful of cheap punches - they don't last too long and can mess things up when they fail (from experience).

Another approach is a step drill bit - a little cleanup of the flash is needed after, but work fairly well.

RIch

Another approach is a step drill bit - a little cleanup of the flash is needed after, but work fairly well.

RIch

I've mostly used step drills which are ok, but they can easily wander and leave you with a hole out of alignment (why I am now looking at punches!).

Hole punches usually give a nicer finish overall but you gotta pay for quality.

Hole punches usually give a nicer finish overall but you gotta pay for quality.

+1Another approach is a step drill bit - a little cleanup of the flash is needed after, but work fairly well.

RIch

I use step drills. Center punch the location, drill with a small (1/8" ?) twist drill and then step drill.

I have an octal punch - a good one- but seldom use it.

I use the step drills for all the other round holes (jacks, small tube sockets, etc. ) anyway, so usually don't bother getting out the punch.

If I could find a good punch for the IEC power jacks at reasonable cost, I'd be tempted. 🙂

+1 for step drills, although these work VERY well, too. They just cost more. DEWALT DWACM1816 Metal Cutting Carbide Holesaw, 1-Inch: Amazon.ca: Tools & Home Improvement

I have one for panel meters. There is NO deburring required. They are designed for SS so they are durable, too.

As far as IEC, I use a dremel and a cutting disc. Not perfect, but I don't look at the back of the amp, either.

The power tube holes and the hole for the meter were made with a DeWalt hole saw.

I have one for panel meters. There is NO deburring required. They are designed for SS so they are durable, too.

As far as IEC, I use a dremel and a cutting disc. Not perfect, but I don't look at the back of the amp, either.

The power tube holes and the hole for the meter were made with a DeWalt hole saw.

Attachments

Last edited:

RS carry a good range. For B9A I use 771-9276 made by Greenlee.

I have used Q-max punches for over 40years and fail to find a supplier that can match RS prices.

Punch & Die Combinations | RS Components

I have used Q-max punches for over 40years and fail to find a supplier that can match RS prices.

Punch & Die Combinations | RS Components

As a journeyman machinist and mechanical engineer since 1984, I can say that if you are going to make several DIY amps and want to punch holes, the punches are the best way to go with sheetmetal. Buy a good quality set of punches such as JonSnell recommends. It's less expensive than machine tools and all the tooling, and doesn't require such a big learning curve to use them.

If this is something you're going to do once or twice in your life, buy a step drill and center drill or punch and practice on a piece of scrap. Read the website information about making holes in metal/machining.

I'm not an EE (but know how to spell it), I'm an ME who learned electronics as a hobby. I'm learning more everyday from the web from sites like this.

If this is something you're going to do once or twice in your life, buy a step drill and center drill or punch and practice on a piece of scrap. Read the website information about making holes in metal/machining.

I'm not an EE (but know how to spell it), I'm an ME who learned electronics as a hobby. I'm learning more everyday from the web from sites like this.

The problem with using a punch is that you need a 5/16 or 3/8" hole for the punch bolt.

To drill a round hole that size in sheet metal, a step drill is the easiest option.

Using larger twist drills in sheet metal doesn't work well for me.

BTW, step drills in larger sizes aren't cheap either.

Also, steel and aluminum present different problems.

Lots of different diy approaches work- my first amp (50+ yrs ago) I recall using a wood bit and brace.

To drill a round hole that size in sheet metal, a step drill is the easiest option.

Using larger twist drills in sheet metal doesn't work well for me.

BTW, step drills in larger sizes aren't cheap either.

Also, steel and aluminum present different problems.

Lots of different diy approaches work- my first amp (50+ yrs ago) I recall using a wood bit and brace.

Was the wood bit still good after using it to make holes in metal?

If you're going to make holes in sheet metal, it's a good investment to buy the correct tools. A lot less expensive and less time consuming than a trip to the ER or scrapping the metal work piece.

Twist drills can be used most effectively and safely by clamping the work piece to a drill press table on top of a piece of wood.

Working safely around high voltages is always stressed when working with electronics. Working safely with power tools also applies. Buy the best quality tools the first time and you don't have to buy them again. If you don't use them again, they can be easily sold secondhand.

If you're going to make holes in sheet metal, it's a good investment to buy the correct tools. A lot less expensive and less time consuming than a trip to the ER or scrapping the metal work piece.

Twist drills can be used most effectively and safely by clamping the work piece to a drill press table on top of a piece of wood.

Working safely around high voltages is always stressed when working with electronics. Working safely with power tools also applies. Buy the best quality tools the first time and you don't have to buy them again. If you don't use them again, they can be easily sold secondhand.

The problem with using a punch is that you need a 5/16 or 3/8" hole for the punch bolt.

To drill a round hole that size in sheet metal, a step drill is the easiest option.

Using larger twist drills in sheet metal doesn't work well for me.

BTW, step drills in larger sizes aren't cheap either.

Also, steel and aluminum present different problems.

Lots of different diy approaches work- my first amp (50+ yrs ago) I recall using a wood bit and brace.

I've had good luck drilling a small (1/8" or so) hole, filing it if necessary to keep it centered as needed, and the using a tapered reamer by hand to enlarge it to the needed pilot hole size. I just hate using unibit/step drills unless I will be cleaning it up substantially after, which is a ton of work by hand.

Small holesaws work well but are a pain to use and may warp thinner material when they "grab" during use.

Of course not! It needed a touch-up with a (correct) sharpening stone.Was the wood bit still good after using it to make holes in metal?

In those days, auger bits were throwaway things in many shops - not like today.

Steel bit vs aluminum sheet isn't much of a battle.

Even good HSS steel bit vs sheet (iron/steel) metal works just fine.

Last edited:

I would recommend the punches too.A guy who builds guitar tube amps recently highly recommended Q-Max punches to me for valves.

They make a very clean hole compared to nibblers etc

I have used a sharp-cornered spade bit.

In a heavy drillpress with blocking and clamps.

NOT recommended!!

This was just before junk step-bits came on the market. Step-bit is now my general go-to under 1".

STILL NEED AMPLE BLOCKING AND CLAMPING! Sometimes it does not grab and spin. When it does, it takes a huge piece of your hand or tummy out, and the resulting stitching is much more costly than it would have been to hire it done at a metal shop.

For an extreme case, 1-1/2" hole in heavy (fusebox) sheetmetal riddled with 1/2" partial knock-outs: two slabs of hard maple flooring, both clamped and screwed-through, and a holesaw urged gently. Hardwood on both sides of the metal constrained the holesaw as it chewed the pre-punched metal. I waited for a well-rested day, and wore the heavy work-jacket.

In a heavy drillpress with blocking and clamps.

NOT recommended!!

This was just before junk step-bits came on the market. Step-bit is now my general go-to under 1".

STILL NEED AMPLE BLOCKING AND CLAMPING! Sometimes it does not grab and spin. When it does, it takes a huge piece of your hand or tummy out, and the resulting stitching is much more costly than it would have been to hire it done at a metal shop.

For an extreme case, 1-1/2" hole in heavy (fusebox) sheetmetal riddled with 1/2" partial knock-outs: two slabs of hard maple flooring, both clamped and screwed-through, and a holesaw urged gently. Hardwood on both sides of the metal constrained the holesaw as it chewed the pre-punched metal. I waited for a well-rested day, and wore the heavy work-jacket.

I need to buy some tools to cut the holes for the valve bases.

I would second the chassis punch, they will give much nicer results.

You'll likely only need two sizes, and they last forever with a little

periodic oiling. Bear in mind their material and thickness limitations.

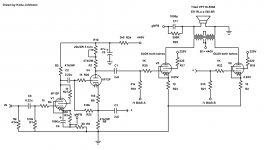

kodabmx- do you have a schematic for the amp shown? It is using 3E25 tubes in PP configuration?

It's actually GU29 with 6F12P phase splitter.

Here's the drawing.

Attachments

- Status

- Not open for further replies.

- Home

- Design & Build

- Equipment & Tools

- Hammond Chassis cutting holes for valves tools