Hi, I am new to this forum.

I joined to know and share ideas about sound box design.

I am currently designing a vented box for the fronts of my PC (5.1 channels). With the shielded speakers I have just bought (they are replacement speakers used in TVs), I am faced with a larger box due to its high Qts, since:

Vb = Qts^2.87 * 15 * Vas

From the formula, Qts is a nice target for reduction to lower Vb. Knowing that Qts is a result of Qms and Qes in parallel, I though that lowering Qms (since it is easier) could effectively lower Qts.

I started with applying diluted fabric conditioner on the spider (the other factor for Qms, aside from the surround). While still wet, I measured T/S parameters using Audua Speaker Workshop just for the sake of knowing what the parameters would be. Qts lowered due to lower Qms, Vas slightly increased, Qes nearly just stayed.

I thought that as soon as the spider will dry, the magic will go, and it did. The parameters returned to their original values.

So I thought about longer-lasting materials, and I thought GREASE!

I diluted bicycle grease with light machine oil and applied it generously on the spider. Measured T/S parameters again. Qms reduced by 28% (and hence, Qts), Vas increased slightly, Qes close to original. (very sorry! Data is at home, I’m currently at work. I will bring them tomorrow).

So after treating the spider with grease, my box volume design reduced by 28%.

I held the bare speaker close to my ears and played music at low volume. Perceptibly, the speaker sounds cleaner, maybe because the coloration of sound due to mechanical Q, is reduced.

I joined to know and share ideas about sound box design.

I am currently designing a vented box for the fronts of my PC (5.1 channels). With the shielded speakers I have just bought (they are replacement speakers used in TVs), I am faced with a larger box due to its high Qts, since:

Vb = Qts^2.87 * 15 * Vas

From the formula, Qts is a nice target for reduction to lower Vb. Knowing that Qts is a result of Qms and Qes in parallel, I though that lowering Qms (since it is easier) could effectively lower Qts.

I started with applying diluted fabric conditioner on the spider (the other factor for Qms, aside from the surround). While still wet, I measured T/S parameters using Audua Speaker Workshop just for the sake of knowing what the parameters would be. Qts lowered due to lower Qms, Vas slightly increased, Qes nearly just stayed.

I thought that as soon as the spider will dry, the magic will go, and it did. The parameters returned to their original values.

So I thought about longer-lasting materials, and I thought GREASE!

I diluted bicycle grease with light machine oil and applied it generously on the spider. Measured T/S parameters again. Qms reduced by 28% (and hence, Qts), Vas increased slightly, Qes close to original. (very sorry! Data is at home, I’m currently at work. I will bring them tomorrow).

So after treating the spider with grease, my box volume design reduced by 28%.

I held the bare speaker close to my ears and played music at low volume. Perceptibly, the speaker sounds cleaner, maybe because the coloration of sound due to mechanical Q, is reduced.

Hehe that's a good idea I guess, you could patent it!

No, not anymore. For being patentable an invention must be new. Publishing an idea before filing destroys the novelty.

Regards

Charles

He's not "publishing" it. He's just throwing around some ideas with a few people on the internet.phase_accurate said:

No, not anymore. For being patentable an invention must be new. Publishing an idea before filing destroys the novelty.

Regards

Charles

You may not even tell a friend about your findings without destroying the novelty. I assume this here is more widespread than just telling a friend, isn't it ?

Regards

Charles

Regards

Charles

For the US, I heard something about a year after publishing it or mentioning on a message board. Not sure about that. It would not surpirse me if the Phillipines follow the US patent law-they used to be a US territory. At any rate, a foreigner can get a US patent anyway.

AFAIK, here to get a patent, you must be the first to find out the idea. So Badeck could write a document about T/S and grease, get a signature from anyone for a witness, then fill a patent. If there's battles about the patent, he could point people to this thread to show he was the first on the idea.

lower power handling?

correct me if im wrong but wouldnt putting grease on the spider hinder cooling of VC?

correct me if im wrong but wouldnt putting grease on the spider hinder cooling of VC?

Just be careful as to what kind of grease and oil you are using on what kind of spider material. The immediate results may be grand, but the end result could be complete failure of the spider and/or other soft-parts on the driver.

Noidster

Noidster

Hello folks! Here's the data (not merely remembering now 🙂 )

It's tab-delimited, but the tabs don't format correctly (showed as space)

Grease Treatment of Spider

T/S Parameters

Parameter Before After % Diff

Re 3.5 3.5 0

Qms 6.527 2.662 -59.21556611

Qes 0.8299 0.8109 -2.289432462

Qts 0.7632 0.6215 -18.56656184

Vas (ft^3) 0.1251 0.13 3.916866507

Le (mH) 0.8005 0.8386 4.759525297

L1 (mH) 0.57 0.582 2.105263158

R1 (ohms) 2.154 1.721 -20.10213556

Fs 64.6 61.52 -4.767801858

Optimum Vented Box Design Results:

Parameter Before After

Vb (vented) (ft^3) 0.864013776 0.497978581 -42.36450915

F3 24.51953104 31.12949595 26.95795812

Fb 34.60248451 39.64319033 14.56746789

So, the results:

Vb decreased by 42%, but at the expense of F3 going up by 27% (a quarter of an octave?), from 24.5 to 31.5 Hz.

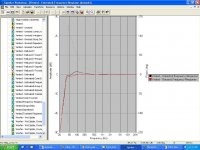

One might think: why not just decrease box volume by 42% w/o applying grease? I plotted the frequency response of such scenario using Speaker Workshop and compared with the Greased plot. The force-reduced plot showed a marked hump of 1.87 db at its Fs, compared to the ideal flat response showed by the greased plot.

So, box design is indeed a choice of tradeoffs, and I will go the greased path 🙂

Here's the on-box FR plot of the force-reduced volume untreated and the treated spider:

It's tab-delimited, but the tabs don't format correctly (showed as space)

Grease Treatment of Spider

T/S Parameters

Parameter Before After % Diff

Re 3.5 3.5 0

Qms 6.527 2.662 -59.21556611

Qes 0.8299 0.8109 -2.289432462

Qts 0.7632 0.6215 -18.56656184

Vas (ft^3) 0.1251 0.13 3.916866507

Le (mH) 0.8005 0.8386 4.759525297

L1 (mH) 0.57 0.582 2.105263158

R1 (ohms) 2.154 1.721 -20.10213556

Fs 64.6 61.52 -4.767801858

Optimum Vented Box Design Results:

Parameter Before After

Vb (vented) (ft^3) 0.864013776 0.497978581 -42.36450915

F3 24.51953104 31.12949595 26.95795812

Fb 34.60248451 39.64319033 14.56746789

So, the results:

Vb decreased by 42%, but at the expense of F3 going up by 27% (a quarter of an octave?), from 24.5 to 31.5 Hz.

One might think: why not just decrease box volume by 42% w/o applying grease? I plotted the frequency response of such scenario using Speaker Workshop and compared with the Greased plot. The force-reduced plot showed a marked hump of 1.87 db at its Fs, compared to the ideal flat response showed by the greased plot.

So, box design is indeed a choice of tradeoffs, and I will go the greased path 🙂

Here's the on-box FR plot of the force-reduced volume untreated and the treated spider:

Attachments

According to Thiele, when you decrease box size by 50%, your F3 should go up i/2 octave.

31 Hz is 37% of an octave higher than 24 Hz, but the Vas is decreased only 42%.

So you decrease Vas by a little less than 50%, and your F3 goes up a little less than half an octave.

Sounds about right.

Looks like what your experient basically did was enable you to squeeze a woofer into a box that it normally would have irregular response in. Nice job.

PS: After the grease is applied, did you find if your SPL @ 1W/1M change at all in the midband?

31 Hz is 37% of an octave higher than 24 Hz, but the Vas is decreased only 42%.

So you decrease Vas by a little less than 50%, and your F3 goes up a little less than half an octave.

Sounds about right.

Looks like what your experient basically did was enable you to squeeze a woofer into a box that it normally would have irregular response in. Nice job.

PS: After the grease is applied, did you find if your SPL @ 1W/1M change at all in the midband?

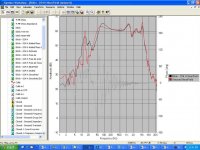

I cannot measure SPL due to the limits of my test equipment, but I did measure nearfield responses for comparison. I have here attached the nearfield responses for the speaker just after 24 H breakin, and after grease treatment.

I guess the large s-curve between 1 kHz and 2 kHz is due to helmholtz behavior of the basket (which is more like windows rather than just support for the magnet and frame) - they're brass plates.

Regarding patents - really I was just humorizing this thing. This is only a discovery, not an invention and Phil patents does not consider discoveries or submissions with prior art (the speaker itself) as valid.

I only think though that maybe with this, we'll be seeing loudspeakers with grease in the spider in the future - the reduction of optimum box volume is i think great (42%) to ignore. Maybe we'll see loudspeakers with spiders having near-zero Q, just there to restore the cone in place, and let the magnet + coil do the vibrating.

I guess the large s-curve between 1 kHz and 2 kHz is due to helmholtz behavior of the basket (which is more like windows rather than just support for the magnet and frame) - they're brass plates.

Regarding patents - really I was just humorizing this thing. This is only a discovery, not an invention and Phil patents does not consider discoveries or submissions with prior art (the speaker itself) as valid.

I only think though that maybe with this, we'll be seeing loudspeakers with grease in the spider in the future - the reduction of optimum box volume is i think great (42%) to ignore. Maybe we'll see loudspeakers with spiders having near-zero Q, just there to restore the cone in place, and let the magnet + coil do the vibrating.

Attachments

patents

Just a few comments on the side-chatter:

1. Chances are that this idea is not patentable.

2. If it were, disclosure on a public forum bars patenting in most countries except the US, where you'd have a year to file.

3. Most people have no real idea what a patent is or does. it is this, and this only: A license to spend a LOT of money to sue someone who infringes the claims of the patent.

Usual disclaimer: I am not an attorney nor patent agent, but I do have several decades of experience with the patent system and litigation.

Just a few comments on the side-chatter:

1. Chances are that this idea is not patentable.

2. If it were, disclosure on a public forum bars patenting in most countries except the US, where you'd have a year to file.

3. Most people have no real idea what a patent is or does. it is this, and this only: A license to spend a LOT of money to sue someone who infringes the claims of the patent.

Usual disclaimer: I am not an attorney nor patent agent, but I do have several decades of experience with the patent system and litigation.

This patent thing is interesting...

But in a patent you are explaining (almost) everything to the others, who can take the idea and with small changes get away from your rigths and make their own system.

Miguel

But in a patent you are explaining (almost) everything to the others, who can take the idea and with small changes get away from your rigths and make their own system.

Miguel

You also need to be pretty confident that none other design had used any spider material that could be considered as something similar to a greased spider. That is difficult. Which means even if you have a patent, and in the process of enforcing it, it still could be invalidated.

There is widespread misperception about intellectual property rights, and that often spills over into this forum. Sy's summary is concise and accurate. I'm not a patent expert either, but I've been involved in various phases of patent issues over the years, including inventor and expert witness.

As for the grease idea; it may meet the novelty requirement, but even so would end up being a pretty narrow claim. As pointed out by another poster, there are other ways to change the properties of a spider. This particular one would not likely be used by manufacturers. It applies mainly to a few aftermarket users, who you ain't gonna catch anyway.

So better to make some secret sauce, with wondrous and mysterious properties (that you extoll with grand flowery language) and made from equally wondrous and mysterious ingredients, that you sell in small bottles at a very high price. And you could paint cones with it, and circuit boards, and treat sores and blindness, and well the possibilities are limitless. Oops, this is spinning out of control.

Sheldon

As for the grease idea; it may meet the novelty requirement, but even so would end up being a pretty narrow claim. As pointed out by another poster, there are other ways to change the properties of a spider. This particular one would not likely be used by manufacturers. It applies mainly to a few aftermarket users, who you ain't gonna catch anyway.

So better to make some secret sauce, with wondrous and mysterious properties (that you extoll with grand flowery language) and made from equally wondrous and mysterious ingredients, that you sell in small bottles at a very high price. And you could paint cones with it, and circuit boards, and treat sores and blindness, and well the possibilities are limitless. Oops, this is spinning out of control.

Sheldon

You need a lot of money to patent anything, and sometimes there are ridiculous patents.

B&W patented the basic speaker design where they put the tweeter on top of the speaker (like on the Nautilus range, and others).

What?!

Yes.

They have a legal fight with Kef, which "copied" their "design" (the supertweeter they put on top, and the coax driver slightly getting out of the box), and doesn't pay anything to B&W for that.

B&W claims payment for infringement of their patent (which is basically just an enclosure design).

Hillarious, but who has the money...

B&W patented the basic speaker design where they put the tweeter on top of the speaker (like on the Nautilus range, and others).

What?!

Yes.

They have a legal fight with Kef, which "copied" their "design" (the supertweeter they put on top, and the coax driver slightly getting out of the box), and doesn't pay anything to B&W for that.

B&W claims payment for infringement of their patent (which is basically just an enclosure design).

Hillarious, but who has the money...

If you go to http://www.muzique.com/clones.htm and read paragraphs 5 and 6 of the Patents section, that is quite interesting. It's in reference to guitar FX pedals.

It basically says that obvious solutions to problems are not patentable. I would consider the tweeter on top idea an obvious solution to a common problem in the field of loudspeaker design. Next they'll be patenting rear firing reflex ports.

I 've been thinking a bit about mechanical dampening since I read the fantastic thread called "Current Driven Loudspeakers and Tranconductance Amplifiers". I thought it might be a good idea to put a more viscous version of ferro fluid in the magnetic gap (perhaps someone could come up with a ferro grease?), which is what I thought you might be referring to in the title of this thread. Obviously not, but do you think it would help reduce the Qms much?

It basically says that obvious solutions to problems are not patentable. I would consider the tweeter on top idea an obvious solution to a common problem in the field of loudspeaker design. Next they'll be patenting rear firing reflex ports.

I 've been thinking a bit about mechanical dampening since I read the fantastic thread called "Current Driven Loudspeakers and Tranconductance Amplifiers". I thought it might be a good idea to put a more viscous version of ferro fluid in the magnetic gap (perhaps someone could come up with a ferro grease?), which is what I thought you might be referring to in the title of this thread. Obviously not, but do you think it would help reduce the Qms much?

Hmnn... the old EV and Jensen 8", 10" and 12"speakers I used eons ago had a pleated fabric for a spider with a sticky, viscous coating that seemed to among other things, stabilize the fabric.

I wonder if this might pre-date this grease idea by several decades??

Prior art notwithstanding....

I wonder if this might pre-date this grease idea by several decades??

Prior art notwithstanding....

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Grease to Lower Speaker Q