No, but I remember Kevin saying he was getting 1500/1700 hours on his SET amp with no soft start, I suppose with softstart, dalay and 60W dissipation it can reach 3K hours.Thanks for the reply. Just these days I was reading Kevin's posts about the GM70, and he wrote that he is replacing the GM70's every 1000 hours, to avoid nasty surprises.

Do you have a more specific link?

Thanks! Erik

Big Boss at Eimac say :

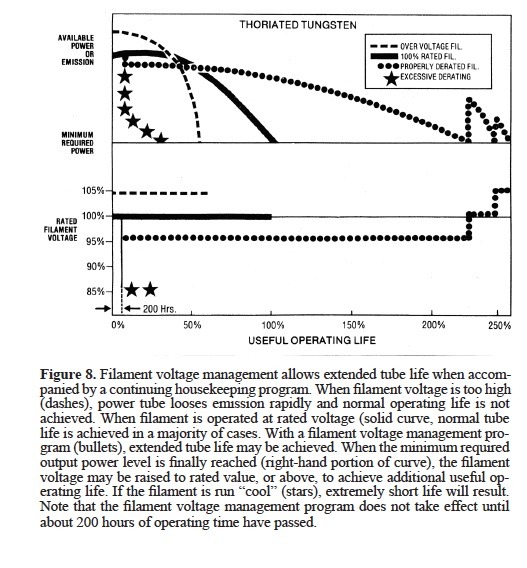

"The key to extending the life of a thoriated tungsten filament

emitter is to control operating temperature. Emitter

temperature is a function of the total RMS power applied

to the filament. Thus, filament voltage control is temperature

control, because temperature varies directly with voltage.

Figure 8 shows that useful tube life can vary significantly

with only a 5% change in filament voltage.

NOTE: If the filament voltage cannot be regulated to

within ± 3%, the filament should always be operated at

the rated nominal voltage specified on the data sheet.

It should be noted that there is a danger to operating the

emitter too much on the “cold” temperature side. It may

become “poisoned.” A cold filament acts as a getter; that

is, it attracts contaminants. When a contaminant becomes

attached to the surface of the emitter, the affected area of

the emitter is rendered inactive, causing loss of emission.

Should this happen, recovery is possible by operating the

filament at full voltage for a period of time. Closely monitored

operation of the filament at slightly below the rated

nominal voltage, however, can extend tube life, if done

properly.

Note that these filament management techniques should

not be applied to oxide cathode tubes, such as the

3CX1500A7/8877. Running oxide cathodes too cold will

result in internal arcs; and once that happens, an oxide

cathode tube is not recoverable.

Of equally great importance to long tube life is the temperature

of the other tube elements and of the ceramicto-

metal seals. Element temperatures can be held within

proper limits by observing the maximum dissipation ratings

listed in the tube’s data sheet. Tube seal temperatures

should be limited to 200°C at the lower anode seal under

worst-case operating conditions. As tube element temperatures

rise beyond 200°C, the release of contaminants

locked in the materials used in manufacturing increase

rapidly. These contaminants can cause poisoning of the

filament, and in turn loss of emission.

When a new power tube is first installed in a transmitter, it

must be operated at rated nominal filament voltage for the

first 200 hours. This procedure is very important for two

reasons. First, operation at normal temperature allows the

getter (a device that chemically binds tube contaminates)

to be more effective during the early period of a tube’s

life, when contaminants are more prevalent. This break-in

period conditions the tube for future operation at lower

filament voltages. Secondly, during the first 200 hours of

operation, filament emission increases. It is necessary for

the life extension program to start at the peak emission

point."

In another doc :

"Filament Voltage

Proper filament v o I t a g e and the allowable departures therefrom are usually specified in the tube data

sheet. In general, quick-heating thoriated tungsten filaments used in the larger power tubes may be operated

over a range of plus or minus 5-percent of the recommended voltage. Slower heating cathode-type

filaments used in small power tubes usually have a filament operating range of plus or minus 10-percent

of the recommended voltage. External anode tubes have a filament voltage range of plus or minus 5-percent.

Some variation in power output must be expected as the filament voltage is varied in this range.

Lower than normal filament voltage will impair the power output of the tube, and higher than normal voltage

will cause critical parts of the tube to run at an excessive temperature, and may even cause damage

to the grid structure in extreme cases. In passing, it should be noted that an inexpensive a.c. type meter

of plus or minus five-percent accuracy can tell the operator little about filament voltage, when the voltage

must be held to the same value of accuracy. Use a good filament voltmeter of known accuracy."

"The key to extending the life of a thoriated tungsten filament

emitter is to control operating temperature. Emitter

temperature is a function of the total RMS power applied

to the filament. Thus, filament voltage control is temperature

control, because temperature varies directly with voltage.

Figure 8 shows that useful tube life can vary significantly

with only a 5% change in filament voltage.

NOTE: If the filament voltage cannot be regulated to

within ± 3%, the filament should always be operated at

the rated nominal voltage specified on the data sheet.

It should be noted that there is a danger to operating the

emitter too much on the “cold” temperature side. It may

become “poisoned.” A cold filament acts as a getter; that

is, it attracts contaminants. When a contaminant becomes

attached to the surface of the emitter, the affected area of

the emitter is rendered inactive, causing loss of emission.

Should this happen, recovery is possible by operating the

filament at full voltage for a period of time. Closely monitored

operation of the filament at slightly below the rated

nominal voltage, however, can extend tube life, if done

properly.

Note that these filament management techniques should

not be applied to oxide cathode tubes, such as the

3CX1500A7/8877. Running oxide cathodes too cold will

result in internal arcs; and once that happens, an oxide

cathode tube is not recoverable.

Of equally great importance to long tube life is the temperature

of the other tube elements and of the ceramicto-

metal seals. Element temperatures can be held within

proper limits by observing the maximum dissipation ratings

listed in the tube’s data sheet. Tube seal temperatures

should be limited to 200°C at the lower anode seal under

worst-case operating conditions. As tube element temperatures

rise beyond 200°C, the release of contaminants

locked in the materials used in manufacturing increase

rapidly. These contaminants can cause poisoning of the

filament, and in turn loss of emission.

When a new power tube is first installed in a transmitter, it

must be operated at rated nominal filament voltage for the

first 200 hours. This procedure is very important for two

reasons. First, operation at normal temperature allows the

getter (a device that chemically binds tube contaminates)

to be more effective during the early period of a tube’s

life, when contaminants are more prevalent. This break-in

period conditions the tube for future operation at lower

filament voltages. Secondly, during the first 200 hours of

operation, filament emission increases. It is necessary for

the life extension program to start at the peak emission

point."

In another doc :

"Filament Voltage

Proper filament v o I t a g e and the allowable departures therefrom are usually specified in the tube data

sheet. In general, quick-heating thoriated tungsten filaments used in the larger power tubes may be operated

over a range of plus or minus 5-percent of the recommended voltage. Slower heating cathode-type

filaments used in small power tubes usually have a filament operating range of plus or minus 10-percent

of the recommended voltage. External anode tubes have a filament voltage range of plus or minus 5-percent.

Some variation in power output must be expected as the filament voltage is varied in this range.

Lower than normal filament voltage will impair the power output of the tube, and higher than normal voltage

will cause critical parts of the tube to run at an excessive temperature, and may even cause damage

to the grid structure in extreme cases. In passing, it should be noted that an inexpensive a.c. type meter

of plus or minus five-percent accuracy can tell the operator little about filament voltage, when the voltage

must be held to the same value of accuracy. Use a good filament voltmeter of known accuracy."