Yes, but the ion/atom still has momentum toward the cathode (allegedly), and the 'thermionic cloud' is very near the cathode, right?The gas ion would be positively charged and strongly attract a (negatively charged) electron. Once the electron reaches the ion, it converts it into a neutral atom, or molecule, which is no longer attracted to 'bombard' the cathode.

Besides, would not the ion be attracted toward the space charge of the electron beam preferentially anyway, very close to where it was formed ? - ie neutralised fairly rapidly after it was formed since that is by definition in a beam of electrons, and so not be attracted toward the cathode at all? I smell a rat.

And there's the catch 22 of ionisation requires beam current requires emission which prevents ion colliding with cathode, allegedly........I smell 2 rats !

Last edited:

Member

Joined 2009

Paid Member

There is no dispute that directly-heated triodes must be preheated to avoid real cathode-stripping.

why would I need a pre-heat for a 2A3 ? - I didn't think voltages were high enough to be an issue for instant-on B+. The 2A3 is not a humungous transmitter tube, although it may once have been used for the task.

Last edited:

There is no dispute that directly-heated triodes must be preheated to avoid real cathode-stripping.

Not all of them: thoriated tungsten filaments (845, GM-70, 211, 811A, 833C, etc.) are not oxide-coated and they are not affected by cathode stripping. They can start cold with full B+.

I would expect that the space charge around the cathode is normally much denser then the electron stream to the anode. That means that a positive ion is very likely to be neutralised by the cathode space charge, but much less likely to neutralised in the anode stream. Once neutralised, the ion still has its momentum towards the cathode though. Perhaps elastic collisions in the space cloud then slow it down? It won't lose much energy/momentum in each collision as electrons are so light, but if there are enough collisions it could work. I don't know, but the books seem to agree that the presence of the space cloud protects the cathode from positive ion bombardment.luckythedog said:Yes, but the ion/atom still has momentum toward the cathode (allegedly), and the 'thermionic cloud' is very near the cathode, right?

Besides, would not the ion be attracted toward the space charge of the electron beam preferentially anyway, very close to where it was formed ? - ie neutralised fairly rapidly after it was formed since that is by definition in a beam of electrons, and so not be attracted toward the cathode at all? I smell a rat.

Yes, but the ion/atom still has momentum toward the cathode (allegedly), and the 'thermionic cloud' is very near the cathode, right?

Besides, would not the ion be attracted toward the space charge of the electron beam preferentially anyway, very close to where it was formed ? - ie neutralised fairly rapidly after it was formed since that is by definition in a beam of electrons, and so not be attracted toward the cathode at all? I smell a rat.

And there's the catch 22 of ionisation requires beam current requires emission which prevents ion colliding with cathode, allegedly........I smell 2 rats !

You need to take into account the rule of thumb used by factory tube design engineers: The emission capability of the cathode should be at least 2.5 times the rated maximum anode current (diodes and triodes) or 2.5 times the sum of the maximum rated anode and screen currents (tetrodes & pentodes). This rule is based on the industry experience that unduly rapid cathode degradation from metal depletion and ion damage does not occur if the anode+screen current is kept below this figure.

It should also noted that the emission capability of oxide cathodes is not a precise value, but somewhat of an arbitary value. A healthy tube may well do much better than 2.5 times the rated value.

Hence the density of electrons near the cathode and within the control grid / cathode space is considerably greater than the density of electrons between the control grid and the anode.

During warm up, the cathode emission capability in indirectly heated oxide cathodes stays practically zero for (typically) about 10 seconds, then ramps past the amount demanded by the amount demanded by the grid and anode voltages in about 0.2 to 0.3 seconds, reaching the design capability (2.5x) in another 2 seconds or so. These times are determined by three factors: a) the flow of heat from heater wire to cathode has a time delay of a few seconds, b) the emission capability of a cathode is acutely sensitive to temperature (a temperature increase at normal operating temperature (~1050K) of 1% results in approx 14% more emission), and as the heater and cathode get near design operating temperature, the rate of temperature increase progressivly slows down toward zero increase.

It is during that 0.2 to 0.3 seconds that the cathode is open to ion damage, because some electron flow to the anode IS occurring, but the density of electrons around the cathode is way below the design value. Electrons that do get through the grid(s) do of course get full acceleration from the anode voltage, and have just as much ion-creating capability as they do when the tube is fully warmed up.

Ions created near the cathode are not the problem. The problem is ions created at or near the anode, as two things apply: a) the electrons have been more fully accelerated, having spent more time in the anode/grid electric field and building up kinetic energy to create ions, and b) the ions created have time to be fully accelerated toward the cathode, which if they get through uncombined in the electron cloud, get carried through to hit the cathode with high kinetic energy.

So, your two rats do not exist.

But, as I & others have said before, practical experience in the vast number of tube-based radios, stereos and TV's manufactured since the introduction of selenium rectifers (Germany late 1940's) and silicon rectifiers (world wide 1962 or so) has shown that not having any HT delay does not significantly hasten cathode wear out that occurs in any case during operation due to a range of causes.

Last edited:

Do not think that because the cathode emission capability is only 2.5 x the anode & grid current, that means the electron density near the cathode is only 2.5 times the density near the anode. It's much MUCH greater.

To see why, picture this:-

Its early morning, not very warm yet, but some electrons have decided to go shopping at the local supermarket. They arrive at the checkout counter on average 1 every 1.1 minutes. It happens that the checkout chick can price up their purchases and take their money at the rate of 1 customer per minute (she's a good fast chick, I've given her a bonus). The queue at the checkout counter won't be long. It won't always be zero - it will fluctuate, occaisonally with one electron in the queue, less often, two.

Now, lets's say its later and temperature has gone up. Electrons now arive at the checkout at the average rate of 1 per minute, just on the number the checkout chick can handle. How long is the queue? Not very long, still averaging just about one electron, 2 a bit more often, rarely, as much as three.

Now, its afternoon. Electrons are averaging 5 every 2 minutes, 2.5 times what the checkout chick can handle. How long is the queue after 30 minutes? Think about it. After 30 minutes, there's 45 electrons in the queue. Fortunately for the poor checkout chick, the sight of all those electrons in the queue causes some electrons just arriving at the store to give up in disgust and go home without buying anything, so the queue doesn't get any worse.

Much the same thing happens with electrons in the cloud around the cathode. The density reaches a stable state where the accumulated negative charge causes about as many electrons to give up and go back to the cathode, as the grid lets thru to the anode. But the electron cloud density around the cathode is MUCH MUCH higher than the density of electrons on their way to the anode.

For those with a mathematical bent, this is called "queuing theory" and "markovian statistics" and is a branch of statistics important to supermarkets, banks, and all manner of electronic engineering topics.

To see why, picture this:-

Its early morning, not very warm yet, but some electrons have decided to go shopping at the local supermarket. They arrive at the checkout counter on average 1 every 1.1 minutes. It happens that the checkout chick can price up their purchases and take their money at the rate of 1 customer per minute (she's a good fast chick, I've given her a bonus). The queue at the checkout counter won't be long. It won't always be zero - it will fluctuate, occaisonally with one electron in the queue, less often, two.

Now, lets's say its later and temperature has gone up. Electrons now arive at the checkout at the average rate of 1 per minute, just on the number the checkout chick can handle. How long is the queue? Not very long, still averaging just about one electron, 2 a bit more often, rarely, as much as three.

Now, its afternoon. Electrons are averaging 5 every 2 minutes, 2.5 times what the checkout chick can handle. How long is the queue after 30 minutes? Think about it. After 30 minutes, there's 45 electrons in the queue. Fortunately for the poor checkout chick, the sight of all those electrons in the queue causes some electrons just arriving at the store to give up in disgust and go home without buying anything, so the queue doesn't get any worse.

Much the same thing happens with electrons in the cloud around the cathode. The density reaches a stable state where the accumulated negative charge causes about as many electrons to give up and go back to the cathode, as the grid lets thru to the anode. But the electron cloud density around the cathode is MUCH MUCH higher than the density of electrons on their way to the anode.

For those with a mathematical bent, this is called "queuing theory" and "markovian statistics" and is a branch of statistics important to supermarkets, banks, and all manner of electronic engineering topics.

Last edited:

Member

Joined 2009

Paid Member

I still don't understand why I should be afraid of 'cathode stripping' on a DHT - or should I say 'filament stripping' ?

If I understand what has been said, the rate of ion generation is tiny until there is a decent flux of electrons at the anode - by which time the electron cloud (virtual cathode) in the DHT is established.

If I understand what has been said, the rate of ion generation is tiny until there is a decent flux of electrons at the anode - by which time the electron cloud (virtual cathode) in the DHT is established.

The alternative, delaying HT/B+, creates a different problem: cathode interface layer. This happens when a valve has a hot cathode but no anode current. Valves designed for computer service or other intermittent operation have special cathode materials to avoid this, but most do not.

So we have a choice: cathode bombardment for a few seconds, or formation of a cathode interface layer. If the valve has a good vacuum then there is nothing to bombard the cathode with.

This is a completely non-existent issue in audio applications.

According to Tomey, Getting the most out of vacuum tubes, 1960, it takes hundreds of hours of zero or near zero anode/screen current operation to produce a significant change in tube characteristics. And operation at full current or a slightly high heater voltage will make the interface layer go away, albiet also a very slow process in the case of anode &screen current.

Early in the days of tube manufacturing, manufacturers realised that purity of materials was key to long tube life. Methods of producing ultra pure nickel for making cathode tubes was developed for example. Then later on it was discovered that adding trace amounts of silicon to the nickel improved emission. So nickel with trace silicon became a routine choice for cathode tubes.

But the trace silicon, a relative insulator, in hot nickel tends to difuse to form an interface layer just under the oxide emission coating, if the emission current is insufficent.

Then computers were invented, which operate tubes cutoff for very long periods. Also TV's with blocking oscillator fame oscillators, which holds the tube cutoff 95% of the time. So, with the early computers and TV's, interface layer growth became a problem.

The solution was simple. They went back to pure nickel cathode tubes. And tubes for computer service were made with nickel especially tested, on every delivery from the nickel refinery for silicon content, to make sure that the refinery hadn't slipped up.

This is a completely non-existent issue in audio applications.

According to Tomer, Getting the most out of vacuum tubes, 1960, it takes hundreds of hours of zero or near zero anode/screen current operation to produce a significant change in tube characteristics.

Tomer is not a good source to cite; it is more of a 'beginner's guide' than an academic study. Although later generation valves did have better immunity to interface resistance, the problem never went away entirely from ordinary quality valves. Degenerative effects and increased flicker noise can be witnessed after hours of running hot but cut-off, not hundreds of hours. Whereas cathode stripping is indeed a non-issue in receiving valves (so there is no need for the delayed application of the HT), interface resistance is a genuine possibility, particularly when we can't be sure of the material quality in modern cathodes.

Incidentally, it grows much faster if the cathode is run hotter than it is supposed to, and in such cases may even grow faster when there is a small anode current than when there is none at all!

No, interface resistance is basically impossible to cure. It is surface poisoning that can be reversed by running the cathode hot and/or pulling a large pulse of anode current. Interface resistance is for life, not just for Christmas.And operation at full current or a slightly high heater voltage will make the interface layer go away, albiet also a very slow process in the case of anode &screen current.

Last edited:

But, as I & others have said before, practical experience in the vast number of tube-based radios, stereos and TV's manufactured since the introduction of selenium rectifers (Germany late 1940's) and silicon rectifiers (world wide 1962 or so) has shown that not having any HT delay does not significantly hasten cathode wear out that occurs in any case during operation due to a range of causes.

Your conclusion is merely wishful thinking.

This is not a comparative study, or even a numeric one, nor do we see any evidence. And most importantly, the criterion for a positive result is merely that somebody thinks that they remember an antique radio working for some lengthy period.

I have already noted that acceptable levels of performance for TV and table radio, or even mid-fi stereos, are not good enough for high quality audio. As usual, you have to know what you are doing, and choose materials accordingly.

If the debate is reduced to anecdotes of this kind, here is mine: as a very young fellow I heard about the valve-tester in my father's research lab. I packed up most of the valves from two table-radios, and had them tested - only to find that all but one were failures. Mostly low gm, but also H-K shorts. Yet - the radios still played (judging in a non-comparative way) fine.

Later, I saved the valves out of working 405-line TV sets. many years later I tried (Mullard) EF80s from this stash in a SE power amp driver circuit - only to find that the gm was so low that I could not reach my gain target.

This outcome is a tribute to the design of old consumer products that can tolerate the use of deeply degraded components, but says nothing about actual degradation of valves over time or usage.

I seem to have to repeat the reasons against crash-starting of cathodes:

Firstly, that there is an increased risk of grid emission, accumulating with each crash-start.

The fact of increased grid-emission is indicated by the Brimar data. The effect is explained by the Philips cathode designer van de Weijer, and his explanation has passed the scrutiny of another cathode designer, Vancil.

We also have a risk of bombardment degradation of the cathode, as described in the various texts.

The risk is that your valves will accumulate excess grid current, noise, and degraded emission. It does not mean that your amplifier will stop working, except in extremity. It does mean that it may perform in a degraded manner.

But in non-critical applications, like amplifiers built for appearances only, it probably makes no difference.

In the case of Bigun's 2A3, I say: There is only one reason to use a 2A3: a very high quality SE or PP power amp for efficient speakers. All other non-critical audio applications can be served better by cheaper and more robust indirectly heated valves. So, to use this very expensive tube without taking all reasonable precautions to maintain its performance seems unwise to me. Espcially against grid-emission. It is perfectly simple and harmonious to build 2A3 amps with PY500A, 6CJ3 or other delay-start, slow rise-time rectifiers. Or you can start the amplifier with high negative bias on the grid, using a switch.

In all things DIY, though, it's your money, and your valves. You may take precautions, or ignore the warnings at your pleasure.

And if we are going to go through the old books looking for guidance, here is another warning against crash-starting:

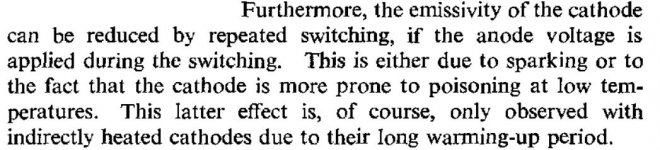

from Herrman & Wagener "The oxide coated Cathode". English Edition, 1951, page 119.

This book was translated at the express wishes of staff of the UK General Electric Company, and the UK Post Office (National PTT at that time). It is based on the actual practical experience of Telefunken, AEG, and Osram GmbH, rather than theoretical speculation.

Attachments

Weijer's description is pure speculation. It was never tested, so you can't use it as a sweeping justification for anything. It's plausible, but then lots of things are plausible that turn out to be irrelevant. Every other published study seems to indicate that 'crash starting' has no detrimental effect on the life of ordinary receiving valves.The effect is explained by the Philips cathode designer van de Weijer, and his explanation has passed the scrutiny of another cathode designer, Vancil.

Weijer's description is pure speculation. It was never tested, so you can't use it as a sweeping justification for anything. It's plausible, but then lots of things are plausible that turn out to be irrelevant. Every other published study seems to indicate that 'crash starting' has no detrimental effect on the life of ordinary receiving valves.

Van de Weijer was a designer of cathodes, and therefore qualified to speak on the subject, and I repeat, Vancil scrutinised it without objection.

Yes it is plausible, and I submit it as an explanation of increased grid emission - which is actually given as a real effect in the Brimar 6BS7 data.

Against this, we have seen no evidence, or authoritative remarks whatsoever.

Where exactly are these published studies? If they exist, we can see whether their judgement criteria were actually relevant to degradation of high-quality audio.

All Vancil said was "I have not seen this phenomenon, but believe it could occur." When it comes to science it doesn't matter who you work for, or how many letters your have after your name, what counts is data and maths. Without those, a hypothesis is nothing more than an educated guess.Van de Weijer was a designer of cathodes, and therefore qualified to speak on the subject, and I repeat, Vancil scrutinised it without objection.

Read the other thread. I have better things to do than repeat the same references over and over, every time a newbie raises the same question.Against this, we have seen no evidence, or authoritative remarks whatsoever. Where exactly are these published studies?

http://www.diyaudio.com/forums/tubes-valves/168981-lets-settle-b-cold-tubes-issue.html

Last edited:

All Vancil said was "I have not seen this phenomenon, but believe it could occur." When it comes to science it doesn't matter who you work for, or how many letters your have after your name, what counts is data and maths. Without those, a hypothesis is nothing more than an educated guess.

One simply gives greater credibility to experienced professionals explaining matters related to their actual expertise.

The only persons claiming that crash-starting presents no risks at all are hobbyists.

Read the other thread. I have better things to do than repeat the same references over and over, every time a newbie raises the same question.

http://www.diyaudio.com/forums/tubes-valves/198739-switch-b-not.html

Oh, the thread that contains no links to any studies whatever of relevance to the debate? Nothing numeric, nothing with any specified judgement criteria.

Your obvious vexation betrays your inability to substantiate the position you take.

Tomer is not a good source to cite; it is more of a 'beginner's guide' than an academic study. Although later generation valves did have better immunity to interface resistance, the problem never went away entirely from ordinary quality valves. Degenerative effects and increased flicker noise can be witnessed after hours of running hot but cut-off, not hundreds of hours. Whereas cathode stripping is indeed a non-issue in receiving valves (so there is no need for the delayed application of the HT), interface resistance is a genuine possibility, particularly when we can't be sure of the material quality in modern cathodes.

Incidentally, it grows much faster if the cathode is run hotter than it is supposed to, and in such cases may even grow faster when there is a small anode current than when there is none at all!

No, interface resistance is basically impossible to cure. It is surface poisoning that can be reversed by running the cathode hot and/or pulling a large pulse of anode current. Interface resistance is for life, not just for Christmas.

I agree that Tomer is an entry-level text aimed at those who would not read more advanced material. But that is why I quoted it. It's not wrong and the OP is not an an engineer advanced in tube based technology or he would not have asked the question.

Even if the interface layer grew significantly in hours or even minutes, it still would not be a problem in audio, where the conditions for growth last just a second or less at each switch-on.

The rest of your comments are just plain wrong. I and thousands of others have 'rejuvinated' tubes with low DC gm just by running the heater on 120% rated voltage for 30 minutes or so. There's only one cause known to cause low DC gm with normal or near normal emission (and near normal high frequency gm) and that's an interface layer.

The rest of your comments are just plain wrong, as lots of books on interface layers would show.

Your conclusion is merely wishful thinking.

This is not a comparative study, or even a numeric one, nor do we see any evidence. And most importantly, the criterion for a positive result is merely that somebody thinks that they remember an antique radio working for some lengthy period.

This is not a personal anecdote. It is the experince of an entire industry.

I have already noted that acceptable levels of performance for TV and table radio, or even mid-fi stereos, are not good enough for high quality audio.

True as regardles distortion, frequency response, power output, noise. But as regards tube life, which was this thread is about, it makes no difference.

This is a personal anecdote and as such worthless. We don't know what sort of tube tester, we don't even know if you used it correctly and interpreted the results correctly.If the debate is reduced to anecdotes of this kind, here is mine: as a very young fellow I heard about the valve-tester in my father's research lab. I packed up most of the valves from two table-radios, and had them tested - only to find that all but one were failures. Mostly low gm, but also H-K shorts. Yet - the radios still played (judging in a non-comparative way) fine.

Later, I saved the valves out of working 405-line TV sets. many years later I tried (Mullard) EF80s from this stash in a SE power amp driver circuit - only to find that the gm was so low that I could not reach my gain target.

The EF80/6BX6 is a TV IF amplifier tube, inherently non-critical in use as far as emission is concerned. And if in a favourable position in the TV set in a good signal area, could be on its last legs without any noticeable effect on picture or sound - the AGC will compensate. (or the user's controls if an old 405 line set - Britain used +ve video modulation so many if not most sets had no AGC. Other countries had negative modulation, so the using the sync pulse amplitude to control AGC is simple, and AGC universal)

This outcome is a tribute to the design of old consumer products that can tolerate the use of deeply degraded components, but says nothing about actual degradation of valves over time or usage.

Good engineering IS about making circuits non-critical, whether cheap radios or expensive high quality gear.

But again, this is a personal anecdote that means nothing. Examples: If you had tested the radio(s) with proper intrumentation, you might have found audio power output had dropped. A drop of 3dB (half power) is not that noticeable - the ear has a logarithmic response. On test, the radio(s) may have had severely degraded RF gain. Unless you routinely listen to distant radio stations, the automatic gain control that all radios have would usually have covered up the problem

And if we are going to go through the old books looking for guidance, here is another warning against crash-starting:

from Herrman & Wagener "The oxide coated Cathode". English Edition, 1951, page 119.

This book was translated at the express wishes of staff of the UK General Electric Company, and the UK Post Office (National PTT at that time). It is based on the actual practical experience of Telefunken, AEG, and Osram GmbH, rather than theoretical speculation.

This was a very good text in its day but is not a good text to quote on this topic. It contains a mix of stuff written between the 1938 and the German publication date 1950. As I explained before, it was commonly thought in the tube industry that not having HT delay would be a problem. But with the introduction of solid state rectification well after this book was written showed the problem was not significant. And tube manufacture advanced quite a bit during and after WW2 -these advances are not covered in this book.

Last edited:

This is not a personal anecdote. It is the experince of an entire industry.

Oh, you are going to claim to speak for a whole industry are you?

Well, where is the substance of your study? where are the methods outlining how crash-started on non-crash-started valves were compared?

where are the numeric results?

You have provided no substantiation of any kind, you have merely issued a tendentious claim.

This was a very good text in its day but is not a good text to quote on this topic. It contains a mix of stuff written between the 1938 and the German publication date 1950. As I explained before, it was commonly thought in the tube industry that not having HT delay would be a problem. But with the introduction of solid state rectification well after this book was written showed the problem was not significant. And tube manufacture advanced quite a bit during and after WW2 -these advances are not covered in this book.

In other words, the text says something incovenient to your argument.

We are instead expected to believe your unsupported anecdote, rather than writers drawing on the mighty experience of Telefunken, AEG, and Osram,

If you have any actual evidence to assist your failing argument, then please let us have it. So far, your material contribution has been exactly zero on this head.

Um, but all you have provided is a couple of cherry-picked sentences from very broad-application books, plus a comment (Weijer) from -of all places- an internet bulletin board! Hardly the epitome of academic rigour.

The verdicts from a number of text books, and of a professional cathode designer have been submitted in favour of the argument that crash-starting conveys some risk. The informed writers - especially those informed by the experience of Telefunken et al. (Note also that the Herrman/Wagener was proof read by a number of staffers at the GEC Research Laboratories, and the GPO Research Station).

Against this, there is exactly zero evidence, and no independent material of any kind (at a professional level) to support for the argument that there is no risk.

Which boils down to: the considered statements of professionals against......... the idle musings of some hobbyists.

Last edited:

- Status

- Not open for further replies.

- Home

- Amplifiers

- Tubes / Valves

- Getter heater & B+ sequencing ?