I can disagree about that for one reason...There is more azimuth tilt in the warped record surface itself than there is from the vertical pivot orientation of the arm tracking that warp. The relative azimuth tilt will of course depend on the profile of the warp and the arm pivot design but, on average, the azimuth tilt introduced by pivot orientation helps compensate for some of the azimuth tilt in the record surface. So, the azimuth tilt that results from pivot orientation can actually be beneficial.

View attachment 1047200

Suppose the warp did not have a tilt as you show in that drawing, and the warp was more towards the label/spindle, as it can sometimes be.

I've had a few records that way, a "bubbled up" area.

Then why aggrevate the situation with a perpendicular pivot as in galu's Technics?

Bottom line I think is to stick to the angled pivot design

Indeed, "record changers" always used that style of pivot mainly because of stacking records adds height.Wiseold, I'm delighted to see that the vertical pivot axis of my vintage Garrard SP25 MKII is not perpendicular to the the arm tube.

However, it's a fiddle to get the removeable headshell to line up square to the platter!

And notice, the Technics 1200's and other "higher-end" single-play used that technique as well.

That's why I say it is "preferred", along with being more difficult to machine, which costs more.

Could you, please, let this topic be about Garrard turntables and not once again about Dual turntables or how great you are at fixing or restoring them?We all know how great you are! You are the greatest and most experienced Dual turntable restoration guy in the Milky Way , but here's about Garrard 301 turntables.

Last edited:

Indeed, "record changers" always used that style of pivot mainly because of stacking records adds height.

Indeed, indeed! The Garrard SP25 MKII is simply a stripped down, single play version of the Garrard AT-60.

Attachments

Indeed again..... I've serviced every model of Garrards through the years.Indeed, indeed! The Garrard SP25 MKII is simply a stripped down, single play version of the Garrard AT-60.

Recently sold off a SL55 on craigs list for $99 - fully restored of course.

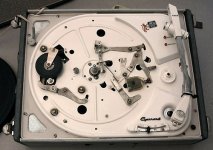

And notice.. the angled vertical pivot? 😉I once had a Garrard 4HF, which I believe was released subsequent to the Garrard 301 in 1957.

It could amost be described as a Garrard 301 with an integral tonearm!

I know that I'm quoting you out of context, but I think in these two phrases lies a big misconception about turntables with thin "ringy" platters.My problem with idler wheel TTs is that the rubber on the idler would eventually harden and transmit ever-increasing amounts of rumble to the platter.

In addition, at least the Garrard, Dual and Elac TTs made in the 60s were stamped steel with not much mass. They would ring like a bell when struck even with their thin vinyl rubber mats (which would also harden over time).

If the idler or belt is in good condition , it will damp the platter vibrations when you press Play, but NOT BEFORE that.

Once in contact with the platter the rubber idler or belt will simply destroy the platter resonances instantly with the condition of a good oiled bearing system for the platter. And you don't have a rubber mat under the vinyl for nothing either.Once the TT SNR is below the vinyl SNR you're absolutely fine with any TT no matter how expensive or cheap.TT technology was improved in many nonessential aspects to attract more audiophiles, yet there are many cheap turntables with not so great mechanics that sound acceptably well.

Garrard 301 conceptually is all you need in a turntable to work very well. You may find fantastically higher SNR turntables from newer Duals, Thorens, Yamaha or Kenwood, but in all truth you won't be able to hear the difference.What you can't hear does not exist...

Last edited:

I was guilty of less than clear writing: I wanted to talk about three different issues: (i) the rumble transmitted by idler wheels to the platter; (ii) the resonances created by thin platters; and (iii) the lack of mass with those platters, which can manifest itself in speed variations.I know that I'm quoting you out of context, but I think in these two phrases lies a big misconception about turntables with thin "ringy" platters.

If the idler or belt is in good condition , it will damp the platter vibrations when you press Play, but NOT BEFORE that.

Once in contact with the platter the rubber idler or belt will simply destroy the platter resonances instantly with the condition of a good oiled bearing system for the platter. And you don't have a rubber mat under the vinyl for nothing either.Once the TT SNR is below the vinyl SNR you're absolutely fine with any TT no matter how expensive or cheap.TT technology was improved in many nonessential aspects to attract more audiophiles, yet there are many cheap turntables with not so great mechanics that sound acceptably well.

Garrard 301 conceptually is all you need in a turntable to work very well. You may find fantastically higher SNR turntables from newer Duals, Thorens, Yamaha or Kenwood, but in all truth you won't be able to hear the difference.What you can't hear does not exist...

I agree that a good condition idler wheel or belt will reduce the platter vibration due to resonance, but it will not remove them entirely. And while you cannot hear the impact of the resonances, they can have an effect on the signal inasmuch as the preamplifier or amplifier circuitry may not take well to the resonances embedded in the signal. Furthermore, unlike belts for the more popular audiophile turntables, it may be difficult to find new idler wheels. Rubber rejuvenation products only work to a certain extent; at some point the rubber is completely oxidized and will not have the resilience when new (I had to junk a laser printer because the rubber wheels could no longer be rejuvenated).

The rubber mat for most audiophile turntables has at least four functions: (i) damping the platter; (i) protecting the platter from scratching if there were direct contact with the platter material itself (here we are talking about home use, as it is clear that cutting lathes have no mats, as I recall so the protection function is really only relevant in home use - commercial pop radio stations have free records so they usually don't care about the condition of their records) (iii) ensuring no slippage between the vinyl and the platter (i.e., they are rotating together with no slip); and (iv) damping the resonance within the vinyl itself, which can be caused by air vibrations, and the energy transmitted by the stylus to the vinyl during play (probably a small amount).

The mass of the turntable platter is part of the system for ensuring that tiny variations in the speed of the drive motor (either idle wheel driver or the motor driving the capstan/pulley for the belt) is evened out by the resistance of the mass of the platter to changes in it rotational speed. I also read that on some turntables, the resistance to rotation caused by the stylus on the heavily cut groove would slow down the rotation of the platter/record but I am not too sure of that.

Worrying about possible and often trivial issues with turntables leads me to believe that some of it is internet-driven propaganda that some read about and adhere to because of their own built-in obsessions with things.

In other words, people that are prone to being "worry-warts".

True, there are some annoying and obvious problems with a mechanical system due to manufacturing and cost limits.

These are the various "tier levels" of manufacturing - even cars, appliances, and clothing.

In that respect, "you get what you paid for", plain and simple.

However, in a "quality" machine, these issues are pretty much rectified and subdued to the point of essentially being non-issues.

The fact that elastic/rubber deteriorates in some cases, doesn't mean there are flaws in the original design.

If this is a "worry", then go with a direct-drive machine, which can have its own "down the road" problems.

In other words, people that are prone to being "worry-warts".

True, there are some annoying and obvious problems with a mechanical system due to manufacturing and cost limits.

These are the various "tier levels" of manufacturing - even cars, appliances, and clothing.

In that respect, "you get what you paid for", plain and simple.

However, in a "quality" machine, these issues are pretty much rectified and subdued to the point of essentially being non-issues.

The fact that elastic/rubber deteriorates in some cases, doesn't mean there are flaws in the original design.

If this is a "worry", then go with a direct-drive machine, which can have its own "down the road" problems.

Vinyl vibrations caused by air at 45rpm...that's entirely new...Are there more strange things like this?

My post did not mention any particular record speed.Vinyl vibrations caused by air at 45rpm...that's entirely new...Are there more strange things like this?

To you, they may be trivial. I may grant you that even some of the issues are really non-issues that are not of any real interest.Worrying about possible and often trivial issues with turntables leads me to believe that some of it is internet-driven propaganda that some read about and adhere to because of their own built-in obsessions with things.

In other words, people that are prone to being "worry-warts".

True, there are some annoying and obvious problems with a mechanical system due to manufacturing and cost limits.

These are the various "tier levels" of manufacturing - even cars, appliances, and clothing.

In that respect, "you get what you paid for", plain and simple.

However, in a "quality" machine, these issues are pretty much rectified and subdued to the point of essentially being non-issues.

The fact that elastic/rubber deteriorates in some cases, doesn't mean there are flaws in the original design.

If this is a "worry", then go with a direct-drive machine, which can have its own "down the road" problems.

I did end up going with a direct drive turntable, Kenwood KD-650. Sure enough there are "down the road" issues as there are no sources for the specialized LSI ICs used in the Kenwood TT. But I gave up on turntables and moved over to CDs in the late 1980s and have never looked back so it is a non-issue for me. But that is not the point of this thread, is it? My position is that I prefer belt-drive turntables to idler wheel turntables and the main reason is idler wheel deterioration and the inability to replace that wheel.

The mass of the turntable platter...

Of course, a high moment of inertia is what you want in a turntable platter when it comes to maintaining constant angular velocity.

Refer to the attachment and note how the mass of the Garrard 301 platter is concentrated at the rim, resulting in a high moment of inertia.

Attachments

Are your turntables much faster than that?My post did not mention any particular record speed.

The issue of air vibrations from playback affecting the record being played exists regardless of speed of the turntable platter.Are your turntables much faster than that?

While my Kenwood was limited to 33 and 45, the Garrards/Duals/Elacs in the 60s and 70s had 78 rpm. Turntables that have the 78 speed are sought after by 78 collectors. At the radio stations I was at, 78 was available. I also saw an old transcription turntable at one station (KGU in Honolulu) that had the 16 speed and the massive platter for playing the 16" transcription records.

- Home

- Source & Line

- Analogue Source

- Garrard 301