Lithium-Ion batteries are awesome. They are simply unmatched for running LED flashlights and headlights. Being only 1 cell is 3.7V, just 1 is needed for any LED.

RadioShack is clearing out old Li-ion cells, and I just got TEN 3.7V 800mAh cells, and also TWO 1140mAh, all for 97 cents each! YEA!!! I'll find a use for these cells, maybe even make a multicell pack.

Charging Li-Ion is not as hard as it may seem. I already made a 2-LED Li-ion flashlight with an simple charger made from LM317 and PNP power pass transistor built in the flashlight, and has NOT EVER failed, despite overdischarging, dropping repeatedly, and submerging in water.

I have a 12V, 3.9AH NiCD battery I made for running high power Halogen lights and horn for my bicycle. I use this 12V battery to also recharge a 3.7V Li-Ion battery made from 2 paralleled 1300mAh 18650 cells for my LED backup headlights. I only have to charge the 12V battery myself. I NEVER have to worry about the state of charge of the Li-ion thanks to the versatility and exact 4.18V max voltage set by the Max1555 IC. When my 12V battery runs too low for Halogen, I switch on the LED's that run for hours more from the Li-ion.

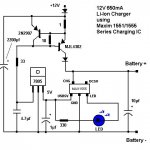

I'm posting the circuit used for the battery charger. The power PNP is heatsinked on the aluminum bottom of the project box, that's then mounted on the handlebars.

By itself, the Max1555 only charges with 300mA MAX and runs hot, but with a PNP transistor, you can make much more, while the chip runs cool at only 100mA, I get over 650mA of charge current.

Any of you mess with Li-Ion for lighting or other uses? Any of you make multicell packs for higher voltage audio projects? I'll use the NiCD and NiMH for high-drain uses, and the Li-ion for everything else.

RadioShack is clearing out old Li-ion cells, and I just got TEN 3.7V 800mAh cells, and also TWO 1140mAh, all for 97 cents each! YEA!!! I'll find a use for these cells, maybe even make a multicell pack.

Charging Li-Ion is not as hard as it may seem. I already made a 2-LED Li-ion flashlight with an simple charger made from LM317 and PNP power pass transistor built in the flashlight, and has NOT EVER failed, despite overdischarging, dropping repeatedly, and submerging in water.

I have a 12V, 3.9AH NiCD battery I made for running high power Halogen lights and horn for my bicycle. I use this 12V battery to also recharge a 3.7V Li-Ion battery made from 2 paralleled 1300mAh 18650 cells for my LED backup headlights. I only have to charge the 12V battery myself. I NEVER have to worry about the state of charge of the Li-ion thanks to the versatility and exact 4.18V max voltage set by the Max1555 IC. When my 12V battery runs too low for Halogen, I switch on the LED's that run for hours more from the Li-ion.

I'm posting the circuit used for the battery charger. The power PNP is heatsinked on the aluminum bottom of the project box, that's then mounted on the handlebars.

By itself, the Max1555 only charges with 300mA MAX and runs hot, but with a PNP transistor, you can make much more, while the chip runs cool at only 100mA, I get over 650mA of charge current.

Any of you mess with Li-Ion for lighting or other uses? Any of you make multicell packs for higher voltage audio projects? I'll use the NiCD and NiMH for high-drain uses, and the Li-ion for everything else.

Attachments

Now I'm good with single cell Li-ion setups, but have to make a good charger for a multicell pack. I figure since this is the power supply design forum, battery chargers go here too.

I realize a 14.4V Li-Ion pack for a portable amplifier is MUCH smaller and lighter than a NiCd or NiMH of nearly the same mAh.

I also have a few questions, as everything I do is DIY and I'm always learning more.

Now a typ 3.7V Li-ion has absolute max charge voltage of 4.2V for max life. Very crucial it never goes over that for each cell.

In say, a 3 cell pack, should I just hook them in series and charge with 12.6V , or should I use special circuits to balance the cell voltage?

I'm thinking of trying to make a discrete charger for many cells, but if you know of any good IC's let me know.

Thanks

Eworkshop1708

I realize a 14.4V Li-Ion pack for a portable amplifier is MUCH smaller and lighter than a NiCd or NiMH of nearly the same mAh.

I also have a few questions, as everything I do is DIY and I'm always learning more.

Now a typ 3.7V Li-ion has absolute max charge voltage of 4.2V for max life. Very crucial it never goes over that for each cell.

In say, a 3 cell pack, should I just hook them in series and charge with 12.6V , or should I use special circuits to balance the cell voltage?

I'm thinking of trying to make a discrete charger for many cells, but if you know of any good IC's let me know.

Thanks

Eworkshop1708

If you are going to use muti-cell Li-Ion packs you should take into account a few precautions. Commercial cells are often equipped with an internal protection against overcurrent, and sometimes even over-voltage. If you don't know what you're dealing with however, it's better to make sure you keep the batteries within their specs.

- NEVER overcharge above 4.2V per cell

- NEVER overdischarge below 2.5V per cell

Then, if you want to extend the life of your cells, it is best to:

- Limit charge/discharge currents to C/2 or C/3 where C is the battery nameplate capacity in Ah

- If you're putting cells in parallel, you multiply the max. charge/dicharge current with the number of parallel connections

- If you're putting multiple cells in series, it is best to have some cell balancing. The easyest way to do so is to interconnect the parallel branches between each series connection. This way, the batteries will balance themselves.

Please don't mess too much with Li-Ion cells... Lithium fires are particularly difficult to put out...

Bakmeel

- NEVER overcharge above 4.2V per cell

- NEVER overdischarge below 2.5V per cell

Then, if you want to extend the life of your cells, it is best to:

- Limit charge/discharge currents to C/2 or C/3 where C is the battery nameplate capacity in Ah

- If you're putting cells in parallel, you multiply the max. charge/dicharge current with the number of parallel connections

- If you're putting multiple cells in series, it is best to have some cell balancing. The easyest way to do so is to interconnect the parallel branches between each series connection. This way, the batteries will balance themselves.

Please don't mess too much with Li-Ion cells... Lithium fires are particularly difficult to put out...

Bakmeel

Lithium cells are old news to torch freaks. If you're interested in torches (flashlights) then have a look at http://candlepowerforums.com

If you want cheap supplies of LEDs, cells and chargers and flashlights:- http://www.dealextreme.com

Lithium cells are popular with (aero)modellers - http://www.ezonemag.com - there are many lithium-powered electric helis on the market.

Older cells are more likely to present a fire risk but latterly improved technology has become widespread without major incident. While you should treat the devices with respect (there's a lot of energy in there and if a fire occurs it can be very difficult to extinguish) the risk of fire with COTS devices used according to the instructions is small.

w

Oh, Lithium cells are vastly superior to NiMh for storage lifetime, NiMh lose their charge disappointingly quickly.

If you want cheap supplies of LEDs, cells and chargers and flashlights:- http://www.dealextreme.com

Lithium cells are popular with (aero)modellers - http://www.ezonemag.com - there are many lithium-powered electric helis on the market.

Older cells are more likely to present a fire risk but latterly improved technology has become widespread without major incident. While you should treat the devices with respect (there's a lot of energy in there and if a fire occurs it can be very difficult to extinguish) the risk of fire with COTS devices used according to the instructions is small.

w

Oh, Lithium cells are vastly superior to NiMh for storage lifetime, NiMh lose their charge disappointingly quickly.

Thanks for the info and the links!

I'm well aware of the fire hazards from Li-Ion. NO worry at all. I've never had an issue with them. In my first Li-Ion days, years ago, I even destroyed a few cells with over 4.5V (oops) from overcharging, but never had them even get hot. Since then I have always made precautions to never overcharge them.

Most of my cells have the built-in protection board, but the 18650 paralleled cells I'm using are naked, and have no issues, because the charger limits it to under 4.2V (4.18), so there will be plenty of cycles and no fires. 😎 Main concern I had was cell voltage going over 4.2 if in a series pack.

*I'm designing on paper right now, a series charger that senses the voltage at the series connection points of the cells, to balance the voltage, maybe using opamps or other sensing. To be continued.....

Thanks,

Eworkshop1708

I'm well aware of the fire hazards from Li-Ion. NO worry at all. I've never had an issue with them. In my first Li-Ion days, years ago, I even destroyed a few cells with over 4.5V (oops) from overcharging, but never had them even get hot. Since then I have always made precautions to never overcharge them.

Most of my cells have the built-in protection board, but the 18650 paralleled cells I'm using are naked, and have no issues, because the charger limits it to under 4.2V (4.18), so there will be plenty of cycles and no fires. 😎 Main concern I had was cell voltage going over 4.2 if in a series pack.

*I'm designing on paper right now, a series charger that senses the voltage at the series connection points of the cells, to balance the voltage, maybe using opamps or other sensing. To be continued.....

Thanks,

Eworkshop1708

there are ready made chargers controllers IC's with balancing functions from linear technology and maxim, to name a few.

If you need high current the new lithium phosfate cells are awsome. they are now used in the dewalt power tools (36V cells). check out A123 systems .. great for rapid charge and many cycles.

If you need high current the new lithium phosfate cells are awsome. they are now used in the dewalt power tools (36V cells). check out A123 systems .. great for rapid charge and many cycles.

Anyone thought abt a low voltage cut off circuit for lithium cells ?

A mosfet (low igs on) based circuit with a presicion reference will suffice. I've seen a design in a magazine long time back..

I am using a Intersil ISL6299 charger with a single cell, not yet used multiple cells...the voltage imbalances are a concern.

A mosfet (low igs on) based circuit with a presicion reference will suffice. I've seen a design in a magazine long time back..

I am using a Intersil ISL6299 charger with a single cell, not yet used multiple cells...the voltage imbalances are a concern.

Li-Ion protection

a simple option is using the seiko S8241 Li-ion protection IC. you need a dual Nmos and some parts, but then you have overvoltage overcurrent and undervoltage protection.

otherwise use a comparator and a big mosfet.

a simple option is using the seiko S8241 Li-ion protection IC. you need a dual Nmos and some parts, but then you have overvoltage overcurrent and undervoltage protection.

otherwise use a comparator and a big mosfet.

Thx basreflex"

a big mosfet u mean ? Low RDS on for loss insertion loss ? ok fine...

but since the voltage is only 3 to 4.2.. ..a low VgS device is necessary RIGHT ?

a big mosfet u mean ? Low RDS on for loss insertion loss ? ok fine...

but since the voltage is only 3 to 4.2.. ..a low VgS device is necessary RIGHT ?

mosfets

check out the fairchild website and look for duals in case you use the seiko part. batteries usually contain an NEC 6Amp or 8amp rated part.

I've used FDMA1024 and FDMA1028 for high frequency switching, but you need soldering skills for these. otherwise select an SO8 part, like the vishay siliconix SI4838 , just an awsome few milliohms and 30A rating.

but be careful, the seiko uses the on resistance of the fets to determine the overcurrent threshold.

check out the fairchild website and look for duals in case you use the seiko part. batteries usually contain an NEC 6Amp or 8amp rated part.

I've used FDMA1024 and FDMA1028 for high frequency switching, but you need soldering skills for these. otherwise select an SO8 part, like the vishay siliconix SI4838 , just an awsome few milliohms and 30A rating.

but be careful, the seiko uses the on resistance of the fets to determine the overcurrent threshold.

Tubular rechargeable cells come in 2 flavours now, protected and unprotected. The protected ones run a few points of a volt lower IIRC but switch themselves off when discharged. This can be a bit disconcerting in an LED torch, as there is little or no tail-off if the output is regulated, one minute you have near-full-power and the next minute nothing, but hey, you can't destroy the cells.

I have a few of these (LI) cells in various applications. You can get good-value off-the-shelf chargers from Aeromodelling suppliers, and I'm sure I've seen a few published circuits, although the commercially-available ones are so good that building your own probably doesn't generate much of a saving unless your application is particularly obscure. I mean, you get battery + charger thrown in in a UKP 9.99 remote control helicopter.

w

I have a few of these (LI) cells in various applications. You can get good-value off-the-shelf chargers from Aeromodelling suppliers, and I'm sure I've seen a few published circuits, although the commercially-available ones are so good that building your own probably doesn't generate much of a saving unless your application is particularly obscure. I mean, you get battery + charger thrown in in a UKP 9.99 remote control helicopter.

w

I've been using nine laptop cells in a series parallel arrangement driving three 5W luxeons in series for a head lamp, the one you wear on your head... but also mount it on my bike when I ride at night (with a DIY CC-CV DC-DC converter) for more than a year now. but only about a few months ago I started using a DIY charger with cell balancing.

the charger I made has trickle charge, normal full current charge, charge termination, manual charge start and cell balancing. 😉 if anyone is interested, I could post the schem but only if I could find it in my PC.

the charger I made has trickle charge, normal full current charge, charge termination, manual charge start and cell balancing. 😉 if anyone is interested, I could post the schem but only if I could find it in my PC.

ur welcome to post it here....or if u can't find the schematic..let least give some details like device used etc...

it has a fixed trickle charge current when the total battery voltage is below 9V (it's designed for three Li-ION cells in series) and switches to normal charge current above that. current is set by low ohm resistors.

voltage references are three TL431's one for each cell. the only hard to find part is the LM1084. similar to LM317 but higher current and low dropoff.

power input is from a 16V 4A laptop adaptor.

still looking for the schematic......

voltage references are three TL431's one for each cell. the only hard to find part is the LM1084. similar to LM317 but higher current and low dropoff.

power input is from a 16V 4A laptop adaptor.

still looking for the schematic......

Thanks for the input!

I have made a first draft schematic on paper of my 3-cell charger, and uses an LM317 for each cell as a reference, and each cell is measured independently by a comparator, and if the cell goes over 4.18V, it gets bypassed by a CCS to keep the other cells charging. 4 LM317's total.

However, I got a newer idea..............

I may just parallel ALL of the cells to make a really large 3.7V battery, and use a small SMPS to get whatever voltage I want from the cells. Then just make a larger MAX1551/1555 charger, and no worry about individual cell voltage!!!

Heck, even make the SMPS output variable for running whatever I want from the 3.7V pack!

No balancing required at all in that case, and easier to take care of, and easier to charge from lower voltage sources!!!

Only concern I have there is a slight bit of wasted power as heat, but i'll just make an efficient SMPS, and not waste power with snubbers or other components, just straight power and some caps to filter.

I have made a first draft schematic on paper of my 3-cell charger, and uses an LM317 for each cell as a reference, and each cell is measured independently by a comparator, and if the cell goes over 4.18V, it gets bypassed by a CCS to keep the other cells charging. 4 LM317's total.

However, I got a newer idea..............

I may just parallel ALL of the cells to make a really large 3.7V battery, and use a small SMPS to get whatever voltage I want from the cells. Then just make a larger MAX1551/1555 charger, and no worry about individual cell voltage!!!

Heck, even make the SMPS output variable for running whatever I want from the 3.7V pack!

No balancing required at all in that case, and easier to take care of, and easier to charge from lower voltage sources!!!

Only concern I have there is a slight bit of wasted power as heat, but i'll just make an efficient SMPS, and not waste power with snubbers or other components, just straight power and some caps to filter.

Li-Ion Battery Charger solution using the Maxim 1555

Hii Friends,

Can any one give the Li-Ion Battery Charger solution using the Maxim 1555.I need the explanation as well as the circuit diagram. Thank You.

Hii Friends,

Can any one give the Li-Ion Battery Charger solution using the Maxim 1555.I need the explanation as well as the circuit diagram. Thank You.

http://datasheets.maxim-ic.com/en/ds/MAX1551-MAX1555.pdf

This datasheet has circuits for the MAX1555. It is a very simple chip to use. You connect a DC voltage to it in the ranges specified 3.7-6V (USB) and 3.7-7V (AC adapter) and you connect it to a battery.

Power is taken from the AC adapter input if it is connected, otherwise the USB.

The capacitors are 1uF ceramic, can get these readily on ebay in 0805 SMT.

The POK output goes LOW when power is connected. The pullup value for this is 100k, it can be used to tell a microprocessor the circuit is working, but you can leave it unconnected.

The chip looks after the battery, that's all there is to it.

w

This datasheet has circuits for the MAX1555. It is a very simple chip to use. You connect a DC voltage to it in the ranges specified 3.7-6V (USB) and 3.7-7V (AC adapter) and you connect it to a battery.

Power is taken from the AC adapter input if it is connected, otherwise the USB.

The capacitors are 1uF ceramic, can get these readily on ebay in 0805 SMT.

The POK output goes LOW when power is connected. The pullup value for this is 100k, it can be used to tell a microprocessor the circuit is working, but you can leave it unconnected.

The chip looks after the battery, that's all there is to it.

w

The MAX155X series is very easy. The hardest part is soldering, but it can be done. I use regular RadioShack perf board, and solder 5 small tinned wires to where I'll put the IC, and heat each wire with the iron and the tinned wire solders itself to the IC pin. A little rosin from the solder makes the IC stick to the board.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Power Supplies

- Fun with Lithium Ion