I don't know if I posted this in the right place the first time, so I've added a link to the thread relating to the problems I'm having with floating voltages.

I would be very grateful if you can help me out with this.

Thanks!

John

http://www.diyaudio.com/forums/showthread.php?s=&threadid=26688

I would be very grateful if you can help me out with this.

Thanks!

John

http://www.diyaudio.com/forums/showthread.php?s=&threadid=26688

Hi John, now you are on the correct forum to ask the question. The easiest way I know of to obtain floating voltages is using separate windings on one or more transformers. If size is not too much of a problem, you should be able to obtain as many separate supplies as needed by using many small transformers because only the higher power parts of your circuits would need to be supplied by bigger transformers.

Thanks Subwo1!

I had been thinking about that. It's the way I'll end up going most likely, but I was curious as to whether or not there was some way I could more affordably seperate a single DC supply.

Even though I only require a small amount of power from some of the supplies, it must be very smooth, so I'll need to add rectifiers, smoothing caps and regulators to each winding. While it isn't going to add up to a lot, I figured it wouldn't be worth spending even this much on it if there was some simpler way I could fraction one DC supply and float it on seperate channels, without having to create new rectified, filtered & regulated channels for each floating voltage.

Again, thank you for the help,

John

I had been thinking about that. It's the way I'll end up going most likely, but I was curious as to whether or not there was some way I could more affordably seperate a single DC supply.

Even though I only require a small amount of power from some of the supplies, it must be very smooth, so I'll need to add rectifiers, smoothing caps and regulators to each winding. While it isn't going to add up to a lot, I figured it wouldn't be worth spending even this much on it if there was some simpler way I could fraction one DC supply and float it on seperate channels, without having to create new rectified, filtered & regulated channels for each floating voltage.

Again, thank you for the help,

John

You're welcome, eeka chu. The separate low power transformers is the simplest way for anyone not experienced in switchmode power supply construction. With the 50 or 60 hz transformers you also do not have to worry about high frequency noise generated by switching converters.

Seperate windings it is! 😀

On the subject of windings... I have a related question....

I just bought a Hakko soldering station from the US, but I have a nasty feeling it's mains transform is designed only for 120v.

I have a few options. One is to run it from a 240v transformer wound to drop the voltage to 120... the other I'm not sure about.

I thought about replacing the actualy transformer inside to make it look a bit neater, so I didn't have a seperate transformer lying around.

My other idea was to have the original transformer rewound with a secondary suitable for the 240v input.

Is it likely that I'll be able to remove the original bobbin from the transformer or is it just going to be more trouble than it's worth? I've hand made a transformer before now but I'm not totally sure on all the ways in which the manufacturers have go about winding them to prevent problems.

John

On the subject of windings... I have a related question....

I just bought a Hakko soldering station from the US, but I have a nasty feeling it's mains transform is designed only for 120v.

I have a few options. One is to run it from a 240v transformer wound to drop the voltage to 120... the other I'm not sure about.

I thought about replacing the actualy transformer inside to make it look a bit neater, so I didn't have a seperate transformer lying around.

My other idea was to have the original transformer rewound with a secondary suitable for the 240v input.

Is it likely that I'll be able to remove the original bobbin from the transformer or is it just going to be more trouble than it's worth? I've hand made a transformer before now but I'm not totally sure on all the ways in which the manufacturers have go about winding them to prevent problems.

John

Oh, you should forget about rewinding the primary of the internal transformer, IMHO. It may have hundreds of turns of fine wire. Besides, it can be a real pain to remove the lacquered laminations form it. However I have done another option in your case. Temporarily hook the internal transformer to a good step-down transformer and then do measurements on the power characteristics of the Hakko transformer. Once you know the voltage and current figures of the windings, you can purchase a 220 volt transformer to substitute it.

Thanks,

I've emailed Hakko to see what the thing is with the transformer. They don't seem to have any presence in the UK.

I wasn't thinking of rewinding the coil myself. I know a number of companies in the UK do customised winding. I thought if transformer cores had been subjected to some form of international standardisation, I could just have the bobbin removed and a new one machine wound, rather than discarding the core and chassis, already there, for a new one.

Knowing manufacturers in general, they've probably specifically shaped the mounting points of the transformer to make it virtually impossible to use anything but their own replacements! 🙂

I was getting tired of using 2.99 wall powered irons, so I figured a nice station would be cool.

I was playing with the idea of getting the 703b, it comes with the two irons and the desoldering tool. But I quite like the results I get with braid and the Future model series comes with lots of funky things that means you don't really need two irons, since the tips pull out while they're still hot. The tips have identity markers electronically written into them, so you can just clip a different tip in and the station will adjust itself!

Yay!

Now I have to wait a few weeks for it to turn up! 😀

I've emailed Hakko to see what the thing is with the transformer. They don't seem to have any presence in the UK.

I wasn't thinking of rewinding the coil myself. I know a number of companies in the UK do customised winding. I thought if transformer cores had been subjected to some form of international standardisation, I could just have the bobbin removed and a new one machine wound, rather than discarding the core and chassis, already there, for a new one.

Knowing manufacturers in general, they've probably specifically shaped the mounting points of the transformer to make it virtually impossible to use anything but their own replacements! 🙂

I was getting tired of using 2.99 wall powered irons, so I figured a nice station would be cool.

I was playing with the idea of getting the 703b, it comes with the two irons and the desoldering tool. But I quite like the results I get with braid and the Future model series comes with lots of funky things that means you don't really need two irons, since the tips pull out while they're still hot. The tips have identity markers electronically written into them, so you can just clip a different tip in and the station will adjust itself!

Yay!

Now I have to wait a few weeks for it to turn up! 😀

you would be better off getting a new transformer....my station works off of 24 volt secondaries which I think is pretty well standard.....just measure your secondaries and you can always place the transformer into a remote box by the outlet

Sounds great. I may consider getting one of those Hakko ones myself.

I'll let you know what it's like if it arrives soon! I think a lot of stations are going towards the cartridge tip idea to make it safer for untrained staff to use them. The tips are about $10 each. Hakko suggests using them for about a week or two, but I suspect that estimate is in a high production enviroment.

Here's mine, complete with very stylish colouring! 😀

An externally hosted image should be here but it was not working when we last tested it.

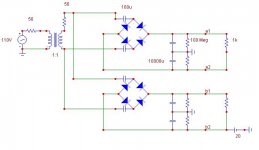

The following is an example of two independent

floating supplies in action from a single transformer.

However, they are not perfect. The DC voltage

is lowered by the decoupling cap (100u) the lower these caps

the lower the voltage, but they cannot be too big.

I hope this helps

Federico

floating supplies in action from a single transformer.

However, they are not perfect. The DC voltage

is lowered by the decoupling cap (100u) the lower these caps

the lower the voltage, but they cannot be too big.

I hope this helps

Federico

Attachments

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Floating voltages