So I was planning on building a small amplifier for the kitchen, and I wanted to have a fixed power chord running through the chassi. But I obviously don't want the metal edges of the chassis to eat away at the chord... So i'm locking for some sort of solution to this. How do I keep the chord firmly tucked in place and not in contact with the metal edges?

/H

/H

Look for a 'cable strain relief bush' (sometimes called 'clip' or 'clamp').

Cable Wire Strain Relief Bush Grommet 16mm (2 Pack) | eBay

Cable Wire Strain Relief Bush Grommet 16mm (2 Pack) | eBay

Attachments

Thanks guys! Knowing what function I need but not knowing the names of it makes guggogolung hard... A bushing! 🙂

The powercons are great to. Don't have shop access so did'nt want any odd shaped connector, just straight drilling.

The powercons are great to. Don't have shop access so did'nt want any odd shaped connector, just straight drilling.

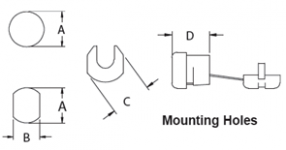

The fixings I mentioned are clamped around the cable then snapped into either a round or an elongated (double D) hole, if you need to prevent rotation.

If necessary, you can make a double D hole by drilling 2 smaller holes side by side then filing out the middle ridges

If necessary, you can make a double D hole by drilling 2 smaller holes side by side then filing out the middle ridges

Attachments

Look at Your computer PSU, but perhaps You need a smaller one.cable strain relief bush

Chandelier stores / factories usually have that kind of things.

I found some different solutions nereby me, so I´ll get to drilling and soldering. 🙂

I'll probably go for the rubber grommet since I don't really plan on moving it around that much.

I'll probably go for the rubber grommet since I don't really plan on moving it around that much.

Easiest stuff to use is a cable gland as you need a simple round hole.

cable glands at Reichelt

PS: as already pointed out by MAAC0.

cable glands at Reichelt

PS: as already pointed out by MAAC0.

Agree with 00940 - use something like it is shown in the attachement. I would never recommend a "thing" like Galu has shown... That is unsafe/old-school...

Edit: As the opener of the thread pointed out, he is using a metal chassis - for us hoppyists, this needs to be connected to PE. Nothing else to be sayed.

Edit: As the opener of the thread pointed out, he is using a metal chassis - for us hoppyists, this needs to be connected to PE. Nothing else to be sayed.

Attachments

Last edited:

To be safe it must be a compression plastic strain relief bush.These absorb the pushing, pulling, and twisting forces that electrical cables may be subjected to during use. They snap into either a round or anti-rotation hole and, when inserted, they compress against the cable. They are, however, best suited to small round or flat cables.I would never recommend a "thing" like Galu has shown... That is unsafe/old-school...

An externally hosted image should be here but it was not working when we last tested it.

Some cable strain reliefs don't provide protection from pulling force. Instead, they are used to allow cables to pass through holes in furniture and enclosures without causing damage to either the cord or the device.

The power cord bushing Galu posted is most often manufactured by "Heyco." It is rated and listed by most safety agencies. It does require a special "double D" punch. The bushings come in different sizes to precisely clamp the various types of cords. They also are specified by the wall thickness of the enclosure. A special plier style tool is the best way to compress and insert the bushing. To get a safety agency approval on the bushing as used in a production piece of gear, the right bushing, proper punch and specific insertion tool must be used.

A compression cord fitting may be used with a rated power cord. Some of the fittings are designed for oval cords, others for round cords.

Using a grommet and a strain relief such as a cable tie to smooth flat metal tab will not meet any safety agency approval I am aware of. However it is a practical solution for one off personal projects.

But for most folks the compression connector previously shown is probably the best bet. But do note it screws in so something must be done to prevent it from rotating and becoming loose. Thread locking compound is a good choice for that.

Costwise, once you have the tooling a Heyco style bushing is the best. It locks in firmly, won't twist and provides a positive resistance against pull out.

For normal folks the compression fitting with thread locking compound is a good choice.

A grommet and strain relief work well when a rated and protected wall mount or desktop power supply is used, but a connector is better.

A compression cord fitting may be used with a rated power cord. Some of the fittings are designed for oval cords, others for round cords.

Using a grommet and a strain relief such as a cable tie to smooth flat metal tab will not meet any safety agency approval I am aware of. However it is a practical solution for one off personal projects.

But for most folks the compression connector previously shown is probably the best bet. But do note it screws in so something must be done to prevent it from rotating and becoming loose. Thread locking compound is a good choice for that.

Costwise, once you have the tooling a Heyco style bushing is the best. It locks in firmly, won't twist and provides a positive resistance against pull out.

For normal folks the compression fitting with thread locking compound is a good choice.

A grommet and strain relief work well when a rated and protected wall mount or desktop power supply is used, but a connector is better.

If You use a rubber grommet, make sure You put a compression thingy inside the chassis in order for the cable not to rotate & to fixate it. Many appliances use a small metal strip with two screws on each side. Look at power plugs & strips.

So I wound up taking to the old saw, and putting an IEC-connector there anyway. But thanks to everybody for the help and tips! 🙂

what a difference one letter can make...a power chord is a staple of heavy metal music, a power cord is an electrical cable.

So I wound up taking to the old saw, and putting an IEC-connector there anyway. But thanks to everybody for the help and tips! 🙂

An excellent decision!

It does require a special "double D" punch.

Drill a hole to accommodate the widest FLAT diameter. Use a rat tail file to carve out the belly of the D's and a flat file to form the squared part. I did this, but it takes quite a bit of skill to insert the cable into the chassis with the strain relief.

For the most part, I've been using IEC connectors, or PEM's. Be attentive to the polarization.

(I've also used 6V/3A wall warts with Jan Didden's "Silent Switcher" -- boy does this make life easy for projects like headphone amplifiers, phono pre, line amplifiers!)

what a difference one letter can make...a power chord is a staple of heavy metal music, a power cord is an electrical cable.

Lol didn't even notice that little slip up! 😛😛😛

- Home

- Design & Build

- Parts

- Fixed power chord washer