Recently I fitted some waveguides to my tweeters (here) I think I did this okay, at least no-one dived in to say otherwise. However there is a problem I hadn't foreseen. The waveguides vibrate audibly due to vibrations from the woofer at tones around 80Hz and 160Hz (the mid and tweeter enclosure is sealed off from the bass driver's but still shares the baffle/walls etc). I'm assuming this is the waveguide vibrating against the baffle, Hopefully its not the tweeter itself :-/

The guides are screwed tightly down at the corners so 'presumably' the plastic must be vibrating between these points. I guess its a relatively thin piece of plastic and quite flat around the corners, with the large weight of the tweeter magnet hanging from the back of it, so I can see (now!) that there could be that sort of tendency.

I didn't really want to glue the wave-guides in, its likely I'll want to make different cabinets in the future, so I'd just put a thin bead of silicone around the edge of the wave-guide as a gasket. But it seems something better is needed. I wondered about casting some kind of larger rubbery gasket into/around the baffle hole to fit more of the waveguide's profile, presumably the cone part of the guide would be quite rigid if I can support that, rather than just the flat area around the edges/corners. Ideally this wouldn't be glued to the wave-guide, just there to support and cushion it, but not sure if that would be sufficient.

Has anyone come across ways of dealing with this?

Thanks

Kev

The guides are screwed tightly down at the corners so 'presumably' the plastic must be vibrating between these points. I guess its a relatively thin piece of plastic and quite flat around the corners, with the large weight of the tweeter magnet hanging from the back of it, so I can see (now!) that there could be that sort of tendency.

I didn't really want to glue the wave-guides in, its likely I'll want to make different cabinets in the future, so I'd just put a thin bead of silicone around the edge of the wave-guide as a gasket. But it seems something better is needed. I wondered about casting some kind of larger rubbery gasket into/around the baffle hole to fit more of the waveguide's profile, presumably the cone part of the guide would be quite rigid if I can support that, rather than just the flat area around the edges/corners. Ideally this wouldn't be glued to the wave-guide, just there to support and cushion it, but not sure if that would be sufficient.

Has anyone come across ways of dealing with this?

Thanks

Kev

I remember having a look at your other thread. Yes, this is a bit of a dillema but should be easy to put in order.

Probably the most important thing is that the waveguide doesn't move in relation to the tweeter, and that the tweeter doesn't move. Since there is greater treble sound pressure near the throat, that is a place that wants strengthening and I'd probably start there. Either way to reach the same end.

These waveguides are thin, and I'd be looking for some way to cast around them to build them up. My own tweeter waveguides are a few inches thick at the throat, which I was advised to do. They are solid acrylic, not specifically meant to be soft.

It would seem reasonable to make the entire baffle and waveguide stiff enough to resist movement, but somewhere something would want to give, I think it should be a point away from the tweeter itself.

So for example if the vibration in question is coming from the woofer mechanically coupling into the baffle then decoupling the woofer might be in order.

Probably the most important thing is that the waveguide doesn't move in relation to the tweeter, and that the tweeter doesn't move. Since there is greater treble sound pressure near the throat, that is a place that wants strengthening and I'd probably start there. Either way to reach the same end.

These waveguides are thin, and I'd be looking for some way to cast around them to build them up. My own tweeter waveguides are a few inches thick at the throat, which I was advised to do. They are solid acrylic, not specifically meant to be soft.

It would seem reasonable to make the entire baffle and waveguide stiff enough to resist movement, but somewhere something would want to give, I think it should be a point away from the tweeter itself.

So for example if the vibration in question is coming from the woofer mechanically coupling into the baffle then decoupling the woofer might be in order.

Last edited:

The waveguide looks large and light and without the stiffening ribs one might expect to see in a commercial product (and that it very likely needs). Is it practical to stiffen it?I didn't really want to glue the wave-guides in, its likely I'll want to make different cabinets in the future, so I'd just put a thin bead of silicone around the edge of the wave-guide as a gasket. But it seems something better is needed. I wondered about casting some kind of larger rubbery gasket into/around the baffle hole to fit more of the waveguide's profile, presumably the cone part of the guide would be quite rigid if I can support that, rather than just the flat area around the edges/corners. Ideally this wouldn't be glued to the wave-guide, just there to support and cushion it, but not sure if that would be sufficient.

Isolating the waveguide from the cabinet with a thick soft gasket with a lot of contact area (and not screwing it down tight) looks good but the tweeter/waveguide assembly would then need supporting. Running bolts from the tweeter mounting to the back of the midrange cabinet is perhaps an option to explore. Bushes perhaps.

Thanks very much, Allen and Andy. Quite a few very workable possibilities there, and I may have a go at a combination of them. I think the waveguide horn-shaped sections are acrylic, so could indeed be bonded to strengthening ribs or even have a solid block of something (if its compatible, maybe body-filler or fibreglass) cast onto the back of them, if I left clearance for the nuts. The round back/fixing plate of the waveguide is polycarbonate and somewhat thicker - its already pretty firm, so if that were braced to the acrylic part it should give a very solid fixing for the tweeter.

I'll have a think about decoupling the waveguide and/or woofer from the baffle. The woofer is already on a thick soft foam gasket so it may be hard to do much more without being radical, but there could be a bit more scope for softening and cushioning the coupling between baffle and waveguide or else supporting the tweeter more directly.

The current cabinets are essentially a kind of long term first prototype, which I'll probably test and tweak as I learn about them. If/when when size is less of an issue I'm hoping to make a more elegant cabinet for the same drivers, and could certainly then plan for better isolation of the woofer or separate/isolated cabinets for the mid + tweeter and the bass.

Thanks again for the ideas,

Kev

I'll have a think about decoupling the waveguide and/or woofer from the baffle. The woofer is already on a thick soft foam gasket so it may be hard to do much more without being radical, but there could be a bit more scope for softening and cushioning the coupling between baffle and waveguide or else supporting the tweeter more directly.

The current cabinets are essentially a kind of long term first prototype, which I'll probably test and tweak as I learn about them. If/when when size is less of an issue I'm hoping to make a more elegant cabinet for the same drivers, and could certainly then plan for better isolation of the woofer or separate/isolated cabinets for the mid + tweeter and the bass.

Thanks again for the ideas,

Kev

Last edited:

I have never really liked the idea of "isolation" as this will inevitably lead to response aberrations. Also, these kinds of vibration problems can be quite insidious and often hard to track down. I would guess that you need a more rigid mounting of the waveguide, not a softer one, but then that's just a guess as to what is actually vibrating. I have had issues like this that turn out to be things that I never would have guessed at in the beginning.

Thanks for the info, most useful. Seems like if I'm unlucky this could take a while to track down, or I could end up moving it around rather than solving it. I think I'll keep things simple to start with then, and see what that does before going further.

My guess for the most likely area to flex/vibrate is the part of the waveguide that fits flush to the baffle. The dimensions there are its largest, the turning moment from the mass of the tweeter's magnet would be greatest, and the relatively thin plastic is quite flat outside of the cone/horn (i.e. with no contours to stiffen it). If this vibrated (say between the mounting screws) it could do so against the baffle, which could explain why its so audible.

Its just a theory so could be wrong, but stiffening that area would be less complicated than many other things I could try, so seems worth a go.

Thanks again,

Kev

My guess for the most likely area to flex/vibrate is the part of the waveguide that fits flush to the baffle. The dimensions there are its largest, the turning moment from the mass of the tweeter's magnet would be greatest, and the relatively thin plastic is quite flat outside of the cone/horn (i.e. with no contours to stiffen it). If this vibrated (say between the mounting screws) it could do so against the baffle, which could explain why its so audible.

Its just a theory so could be wrong, but stiffening that area would be less complicated than many other things I could try, so seems worth a go.

Thanks again,

Kev

Last edited:

This is quick and dirty and cheap. You might try sticking some soft modelling clay, like Plasticine, on the back of the waveguide. Adds mass and lots of damping.

If it works, then you can figure out how to make it stick permanently because it never drys out.

If it works, then you can figure out how to make it stick permanently because it never drys out.

Heh, that would be great, thanks for the suggestion. TBH I wouldn't expect it to be enough, but its so simple to try that its definitely worth a go!

Cheers

Kev

Cheers

Kev

Heh, that would be great, thanks for the suggestion. TBH I wouldn't expect it to be enough, but its so simple to try that its definitely worth a go!

Cheers

Kev

Plumbers' putty is even heavier as it is loaded with sand or minerals. I have also seen people apply a liquid adhesive like liquid nails to back of waveguides. Add sand to wet glue to add mass. Iron filings if you have them. Lead shot also works. I bet this fixes it.

This is quick and dirty and cheap. You might try sticking some soft modelling clay, like Plasticine, on the back of the waveguide. Adds mass and lots of damping.

If it works, then you can figure out how to make it stick permanently because it never drys out.

If you want something "semi-permanent" then look to pure silicone caulk. (..this can still be "cut-out" from the baffle later on.) You can also add a "filler" to it like xrk971 mentions above.

Still, the Plasticine should do an even better job of damping (than pure silicone caulk alone), if not as good keeping the waveguide in place.

Last edited:

Thanks everyone for the ideas on putty and caulk. I had a go this morning with some blu-tac loaded with various metal nuts, sadly it didn't stop the audible vibrations, though it perhaps changed the frequency marginally.

I'm growing more convinced that it is likely to be the flat face (edges/corners) of the waveguide that is flexing wrt the baffle. I can flex them with a finger, so its as if the weight of the tweeter is supported on a spring (albeit a stiff one). If so, then glueing it strongly to the baffle should help, but I don't want to do that so perhaps I could instead glue it to a stiff metal frame, and screw the whole thing into the baffle.

If I cast material around that frame and the rest of the waveguide it should be even better. Its awkward to leave clearance for getting at the tweeter fixing nuts though, so perhaps I could just use the studs to locate the tweeter and instead clamp it down using a bar across the back of the tweeter.

Cheers

Kev

I'm growing more convinced that it is likely to be the flat face (edges/corners) of the waveguide that is flexing wrt the baffle. I can flex them with a finger, so its as if the weight of the tweeter is supported on a spring (albeit a stiff one). If so, then glueing it strongly to the baffle should help, but I don't want to do that so perhaps I could instead glue it to a stiff metal frame, and screw the whole thing into the baffle.

If I cast material around that frame and the rest of the waveguide it should be even better. Its awkward to leave clearance for getting at the tweeter fixing nuts though, so perhaps I could just use the studs to locate the tweeter and instead clamp it down using a bar across the back of the tweeter.

Cheers

Kev

Last edited:

If the weight of the tweeter is bouncing on the soft spring of the thin waveguide then fixing the mouth of the waveguide strongly to the baffle is not going to be a solution. You need to support the weight of the tweeter. An easy way to do this is with short struts/bolts to the back of the midrange cabinet. If you do this then the mouth of the waveguide would likely benefit from being softly mounted so that the thin waveguide is not driven by the relative motion between points a large distance apart on the cabinet.I'm growing more convinced that it is likely to be the flat face (edges/corners) of the waveguide that is flexing wrt the baffle. I can flex them with a finger, so its as if the weight of the tweeter is supported on a spring (albeit a stiff one). If so, then glueing it strongly to the baffle should help, but I don't want to do that so perhaps I could instead glue it to a stiff metal frame, and screw the whole thing into the baffle.

An alternative could be a frame around the mouth of the waveguide attached to a frame to support the tweeter which stiffens the whole tweeter/waveguide assembly like the frame of the woofer. Again I would be tempted to use a softish gasket to isolate the assembly from the cabinet motion but the pros and cons of this could be investigated separately.

Thanks Andy. I was heading more towards your second option, so its good that you think it may work.

I'd like to make the tweeter/waveguide assembly work as a unit if possible, it should hopefully pay back in the future if/when I build different cabinets for it.

Cheers

Kev

I'd like to make the tweeter/waveguide assembly work as a unit if possible, it should hopefully pay back in the future if/when I build different cabinets for it.

Cheers

Kev

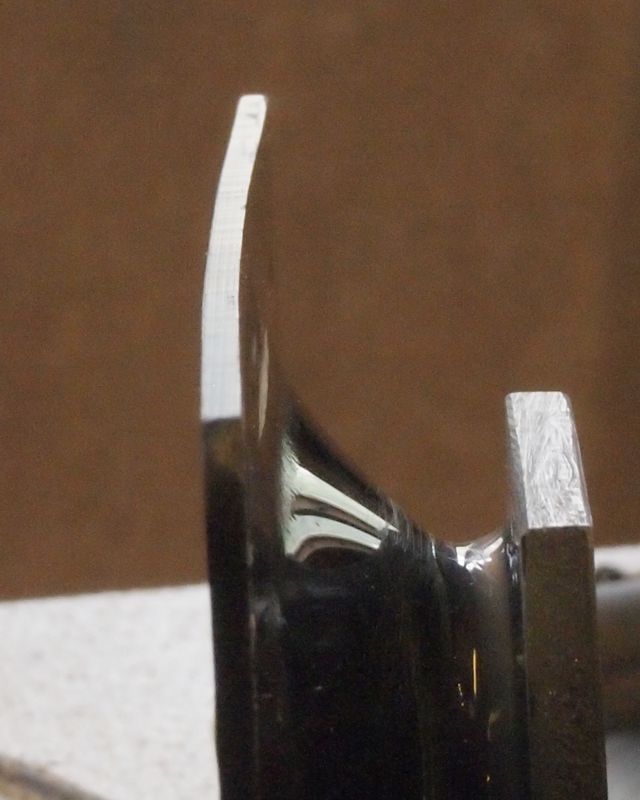

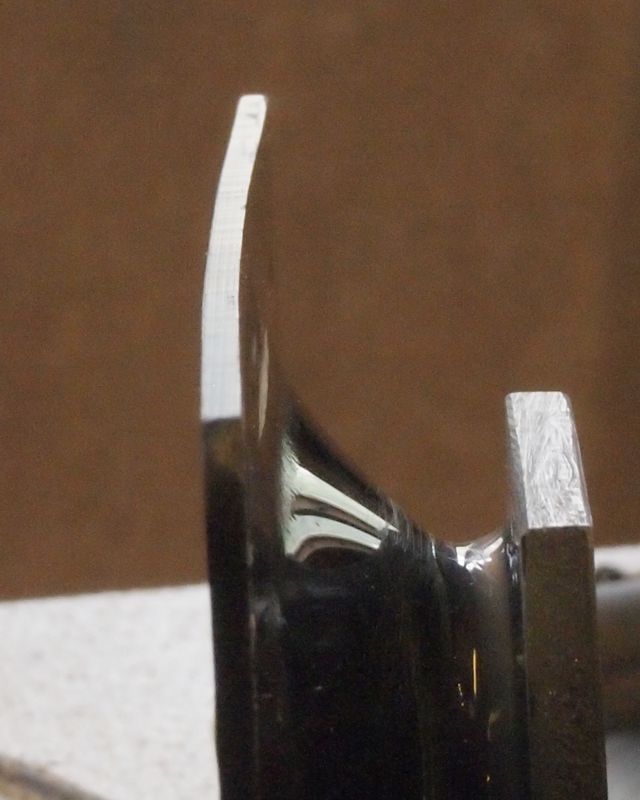

I was just putting a flat on the tweeter mounting plate, and noticed something else. If you look along the edges of the wave-guide all four are curved slightly.

Apologies for the poor photo, I tried to get the light to glint off the edge to make it more visible.

As I elected to put the screws at the corner, which are the lowest point, I can therefore tighten these without pulling the majority of the waveguide flush with the baffle. I guess even if it were flush it could still vibrate, but I think it supports my theory of this being the weakest link.

I have a plan: I'm going to buy some 8mm thick acrylic, cut an oval in it and solvent-weld to the back of the waveguide as a more rigid frame. I'm then going to clamp the tweeter down to this frame with long screws and a bar across the back of the tweeter, such that it is pushed firmly against the back of the waveguide, rather than hanging off it. As that would still put a compression force on the waveguide i'm going to first pack lots of fibreglass/resin filler between the 8mm frame and the tweeter mounting plate. So effectively the existing waveguide will become more of a surface skin than a structural part.

Cheers

Kev

Apologies for the poor photo, I tried to get the light to glint off the edge to make it more visible.

As I elected to put the screws at the corner, which are the lowest point, I can therefore tighten these without pulling the majority of the waveguide flush with the baffle. I guess even if it were flush it could still vibrate, but I think it supports my theory of this being the weakest link.

I have a plan: I'm going to buy some 8mm thick acrylic, cut an oval in it and solvent-weld to the back of the waveguide as a more rigid frame. I'm then going to clamp the tweeter down to this frame with long screws and a bar across the back of the tweeter, such that it is pushed firmly against the back of the waveguide, rather than hanging off it. As that would still put a compression force on the waveguide i'm going to first pack lots of fibreglass/resin filler between the 8mm frame and the tweeter mounting plate. So effectively the existing waveguide will become more of a surface skin than a structural part.

Cheers

Kev

Attachments

This is starting to sound good. Give some thought to mounting behind a baffle to allow some mouth extension/termination, which may be especially helpful at top and bottom.

Thanks Allen, thats reassuring. It'll be a few days before the acrylic arrives but no doubt time will tell. Mounting behind a baffle could be difficult with the current cabinet, but it would certainly be a plan for future cabinets so I'll allow for it in my modifications.

Cheers

Kev

Cheers

Kev

I would be cautious with the solution welding. The waveguide is certainly NOT acrylic and may not "weld" to Acrylic. You may end up with a mess on your hands. I would suggest epoxy since it will stick well to virtually any plastic.

Looks like some weak QC on that waveguide.

Looks like some weak QC on that waveguide.

I was just putting a flat on the tweeter mounting plate, and noticed something else. If you look along the edges of the wave-guide all four are curved slightly.

Apologies for the poor photo, I tried to get the light to glint off the edge to make it more visible.

As I elected to put the screws at the corner, which are the lowest point, I can therefore tighten these without pulling the majority of the waveguide flush with the baffle. I guess even if it were flush it could still vibrate, but I think it supports my theory of this being the weakest link.

I have a plan: I'm going to buy some 8mm thick acrylic, cut an oval in it and solvent-weld to the back of the waveguide as a more rigid frame. I'm then going to clamp the tweeter down to this frame with long screws and a bar across the back of the tweeter, such that it is pushed firmly against the back of the waveguide, rather than hanging off it. As that would still put a compression force on the waveguide i'm going to first pack lots of fibreglass/resin filler between the 8mm frame and the tweeter mounting plate. So effectively the existing waveguide will become more of a surface skin than a structural part.

Cheers

Kev

Ah! Why not "shim" it? Use some really heavy vinyl like for greenhouses. Maybe several thicknesses. BTW, Vinyl is a very good damper - dense and floppy.

In fact, since you're going to mount it on a plate, why not fill the gap with modelling clay? Like I said it damps like crazy and will seal.

I hate to see you spending much time or money on a kind of cheap component.

Last edited:

Thanks very much for the warning, I'll do a test first, before plunging in with the solvent. The pellegrene acoustics website says they are "acrylic waveguides available with polycarbonate mounting plates" which is what I was going on, and I know acrylic can be vacuum formed so I wasn't aware of any conflict, but i appreciate words and reality may differ so definitely better safe than sorry.I would be cautious with the solution welding. The waveguide is certainly NOT acrylic and may not "weld" to Acrylic. You may end up with a mess on your hands. I would suggest epoxy since it will stick well to virtually any plastic.

Looks like some weak QC on that waveguide.

Cheers

Kev

Yeah, I thought of casting it's profile in body filler or using a softer shim of some kind. My concern is that it already circumvented the silicone I had filling the gap; presumably it vibrates out as well as in, probably in combo with the weight of the tweeter vibrating and flexing against the screwed-down corners. So i wanted a good bond that will work in tension as well - very little is as good as a solvent weld in that respect when it comes to acrylic. Of course if it turns out not to be acrylic then that idea may change.Ah! Why not "shim" it? Use some really heavy vinyl like for greenhouses. Maybe several thicknesses. BTW, Vinyl is a very good damper - dense and floppy.

In fact, since you're going to mount it on a plate, why not fill the gap with modelling clay? Like I said it damps like crazy and will seal.

I hate to see you spending much time or money on a kind of cheap component.

Cheers

Kev

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Fitting waveguide to baffle - vibrations