I have had my Ferrograph F307 Mk2 from new having purchased it as a student in 1975. So I'm rather fond of it!!

It has developed a fault - the mains fuse blows on power up and a local vintage amps repair firm has confirmed what I thought - the main transformer has failed somewhere deep in the windings.

Replacements are not available so I am looking at a possible rewind. The schematics (attached) indicate an output voltage between A and B of 70V but do not confirm what it is between X and Y. Am I right to think that it's the same?

between X and Y. Am I right to think that it's the same?

between X and Y. Am I right to think that it's the same?

It has developed a fault - the mains fuse blows on power up and a local vintage amps repair firm has confirmed what I thought - the main transformer has failed somewhere deep in the windings.

Replacements are not available so I am looking at a possible rewind. The schematics (attached) indicate an output voltage between A and B of 70V but do not confirm what it is between X and Y. Am I right to think that it's the same?

Attachments

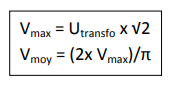

It seems that this secondary winding of the transformer is used for the preamplifier part on the diagram it is mentioned -42V therefore the winding must be in Vac 42/1.414 = 29.69Vac therefore 30Vac roughly speaking!

View attachment 1084107

Many thanks for coming back with some thoughts. To be honest, I'm an electrical engineer, not and electronic engineer and so I am somewhat at sea here. I can see in the schematics that the x & y output from the power supply is coming out of a rectifier and so I assumed that we are talking DC here, not AC? I can see a number of voltage references around the diagram and thought that these were test points during set up. The -42V marker is on the X input but after it has gone through a 2.2k ohm resistor which I assume would reduce the voltage from that arriving from the power supply?

Or am I (as I suspect I might be) talking complete garbage!

Or am I (as I suspect I might be) talking complete garbage!

The preamp stage consumes nothing at all, in other words the voltage drop in the 2.2K is insignificant after the easiest way is to use a lab power supply to replace the built-in power supply and thus see the exact voltages that It's necessary; but on this kind of old stuff it's frankly not very critical voltages of 29Vac in transformer secondary are common!

Hi again and many thanks for your helpful advice. I thought that a rectifier turned AC to DC so that shows how ignorant about all this I am!

Thanks again.

Thanks again.

It is obvious that the alternating voltages that I mention are at the terminals of the transformer and BEFORE the rectifier bridge of course.

Sorry to display my complete ignorance of all this but where does the 1.414 come from in your calculation Vac 42/1.414 = 29.69Vac

You need separate secondaries of 30 and 45 volts which isn’t going to be easy off the shelf. What are your thoughts on replacing/rewinding?

It was suggested by a friend that I should disconnect the secondary connections, insert a 60W filament bulb into the primary connections and test the primary windings. If they have failed the lamp will stay on. If all is ok, the lamp will flash and then go out. If the transformer has failed I have been recommended a possible rewind solution with from Transformer Equipment Ltd in Sandwich Kent but I guess that won't be cheap. One other idea would be to try to squeeze two separate devices in to give the two outputs. Any other ideas gratefully received!

With due respect, I think as an EE you should be aware of it?!?Sorry to display my complete ignorance of all this but where does the 1.414 come from in your calculation Vac 42/1.414 = 29.69Vac

Best regards!

Thanks for that - no - I have long forgotten any learning on transformers - I haven't handled one for decades. I do find it frustrating that sites like this often seem to be frequented by people like you keen to put others down rather than offering help and support. Luckily for me, some of your colleagues have been much more willing to give me good sound advice.With due respect, I think as an EE you should be aware of it?!?

Best regards!

So, and also with due respect, if you don't have anything helpful to add to my understanding of the problem, just keep out of it.

You put the lamp in series.

Dim Bulb Tester, look it up.

You do have a multi meter?

You might get ready transformers with about same ratings for less effort and money than rebuilding it.

You can put one or both in a separate case.

But transformer failure means a deeper fault most of the time.

So check all the devices in the output stage, and so on, a new transformer with all that could add up to a lot of expense.

One poster here kept the unit as is, but the output board was changed to Class D, externally it looks the same, and pre amp etc. are retained. Even speaker relay was retained.

It is a recent post.

You can think of that as well.

Dim Bulb Tester, look it up.

You do have a multi meter?

You might get ready transformers with about same ratings for less effort and money than rebuilding it.

You can put one or both in a separate case.

But transformer failure means a deeper fault most of the time.

So check all the devices in the output stage, and so on, a new transformer with all that could add up to a lot of expense.

One poster here kept the unit as is, but the output board was changed to Class D, externally it looks the same, and pre amp etc. are retained. Even speaker relay was retained.

It is a recent post.

You can think of that as well.

Last edited:

Many thanks for your help and advice - very much appreciated. Yes - I will put the lamp in series so I don't trip anything if the primaries have lost their resistance. Yes - I have a multi meter so will see what the resistance of the primary is before the test - may even confirm that it's had it.You put the lamp in series.

Dim Bulb Tester, look it up.

You do have a multi meter?

You might get ready transformers with about same ratings for less effort and money than rebuilding it.

You can put one or both in a separate case.

But transformer failure means a deeper fault most of the time.

So check all the devices in the output stage, and so on, a new transformer with all that could add up to a lot of expense.

One poster here kept the unit as is, but the output board was changed to Class D, externally it looks the same, and pre amp etc. are retained. Even speaker relay was retained.

It is a recent post.

You can think of that as well.

Yes - I imagine that repairing the transformer might be eye wateringly expensive so once I can see where the problem might be I will hand it over to a specialist vintage repair shop as my next move. Any suggestions on suitable firms will be gratefully received.

Thanks again for your help and advice.

If repairing the transformer is eye-wateringly expensive then so will the bill from a vintage repair shop. He’s going to want retail on top of the retail you’ll get charged for a rewind. Plus $100 an hour.

Thats why you DIY - when a repair like this ends up costing $300. What I would do if I were in your position is buy a pair of toroids from Antek (2x24V 200 VA, and a 32V/25 VA), stack them and bolt them in where the old one was. $75 landed cost in the states, usually not much more elsewhere - and I seriously doubt one can get ANY transformer rewound for $75. Even a teeny tiny one. Fixing it for myself, I’d rewind it - myself. Fixing for a customer, I’d go with the Antek pair because that will give him the lowest possible bill the quickest. A proper repair shop might consider that too much of a hack - I don’t.

Thats why you DIY - when a repair like this ends up costing $300. What I would do if I were in your position is buy a pair of toroids from Antek (2x24V 200 VA, and a 32V/25 VA), stack them and bolt them in where the old one was. $75 landed cost in the states, usually not much more elsewhere - and I seriously doubt one can get ANY transformer rewound for $75. Even a teeny tiny one. Fixing it for myself, I’d rewind it - myself. Fixing for a customer, I’d go with the Antek pair because that will give him the lowest possible bill the quickest. A proper repair shop might consider that too much of a hack - I don’t.

Thanks ever so much for this excellent advice. This all started with a local 'expert repair shop' confirming that the transformer was shot and suggesting doing as you say but not knowing where or how to go about it. After having the amp for about three months I gave up and took it back off him with the idea of repairing it myself. I thought the rewind route might be for me the easiest option as I'm no electronics wizard and so thought that replacing like for like was my best option. However I agree that I will probably be horrified by a rewind cost and your suggestion is how I am going to proceed once I've confirmed nothing else is causing the problem in the first place. The 'expert' said it was the transformer but I think I will just test it before proceeding further.

Many thanks again for your guidance and advice.

Many thanks again for your guidance and advice.

There are a lot of things that can cause the main fuse to blow instantly - I’d definitely confirm the trafo before proceeding. Could just be a faulty voltage selector switch that somehow shorts between taps (Although less likely). Could be a bad rectifier - and that’s just as likely as a short in the trafo. It’s an easy test if you pull the trafo - put it on a dim bulb and see what happens. It shouldn’t draw much current with no load. If it does it’s toast.

The two transformer trick will work - the only hurdle is making sure they fit. Toroids are more space efficient per volt-amp than old EIs so that works in your favor. I’m assuming the old one was an EI. If a 200 VA is too big then the old one couldn’t possibly been more than 100 VA so that size would work. The little one doesn’t need to be much current at all. The lion’s share of the work is mounting them. I would make an adapter plate out of thick sheet metal stock, but drilling a hole in the chassis and running a bolt thru the center would work.

The two transformer trick will work - the only hurdle is making sure they fit. Toroids are more space efficient per volt-amp than old EIs so that works in your favor. I’m assuming the old one was an EI. If a 200 VA is too big then the old one couldn’t possibly been more than 100 VA so that size would work. The little one doesn’t need to be much current at all. The lion’s share of the work is mounting them. I would make an adapter plate out of thick sheet metal stock, but drilling a hole in the chassis and running a bolt thru the center would work.

- Home

- Amplifiers

- Solid State

- Ferrograph F307 Mk 2 transformer failure