If instead each power transistor you imagine one hamburger, which have the same price, isn't impression so crazy 😉 .

My personal favorites

Guys,

For those among you interested in MJL21194/21193, check out my post in the trading forum.

It's definitely a favorite of mine, along with the 2SA1216/2sc2922 from Sanken.

Can't really say which one I like best, they're both outstanding devices.

Regards,

Xcel

Guys,

For those among you interested in MJL21194/21193, check out my post in the trading forum.

It's definitely a favorite of mine, along with the 2SA1216/2sc2922 from Sanken.

Can't really say which one I like best, they're both outstanding devices.

Regards,

Xcel

Source of 2SC5200/A1943

Hi Rajeev ,

I need to get some 2SC5200/A1943. Where did you get yours and how much did they cost ?

Thanks.

Ashok.

ashokm(at)sify.com

Hi Rajeev ,

I need to get some 2SC5200/A1943. Where did you get yours and how much did they cost ?

Thanks.

Ashok.

ashokm(at)sify.com

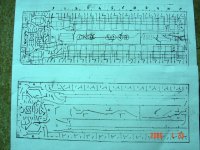

I have cut the boards and will be painting them with enamel paint soon.

K-amps

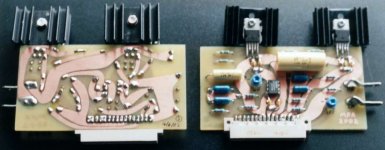

Yes it is looking like the holton boards the only difference is that he has

put the devices in the centre and I have put them on both sides .

Ashok

I have already told you that you can get them from Mumbai , regarding

dealer go to PRAMASHAW RADIO & ELECTRONICS CO.

I had inquired about your wellbeing after the tsumani had hit chennai

coast , but you did not reply .

cheers

K-amps

Yes it is looking like the holton boards the only difference is that he has

put the devices in the centre and I have put them on both sides .

Ashok

I have already told you that you can get them from Mumbai , regarding

dealer go to PRAMASHAW RADIO & ELECTRONICS CO.

I had inquired about your wellbeing after the tsumani had hit chennai

coast , but you did not reply .

cheers

Attachments

That is one heck of a lot of tedious work  Have you not considered investing in a UV lightbox? It only takes a couple of boards like that to make it worthwhile IMO.

Have you not considered investing in a UV lightbox? It only takes a couple of boards like that to make it worthwhile IMO.

Have you not considered investing in a UV lightbox? It only takes a couple of boards like that to make it worthwhile IMO.

Have you not considered investing in a UV lightbox? It only takes a couple of boards like that to make it worthwhile IMO.I had inquired about your wellbeing after the tsumani had hit chennai

Hi Rajeev,

Sorry about not replying to that. I really don't remember seeing that. I'm sorry. I was very busy at the time with guests and my mind was being over worked. Must have slipped up .

Thanks for refreshing my memory about the shop. I will try there. My trip has been postponed.

Cheers,

Ashok.

It should do for testing out the validity of the circuit. It must be much faster to do it at home than to get it done out.

I'm sure not many people will 'see' that board.

DIY of course.

I'm sure not many people will 'see' that board.

DIY of course.

I hand draw my PCBs too. It's because PCBs are art!🙂 Plus it's about as DIY as you can get.Bill Fitzpatrick said:If I made boards like that I'd be too embarrased to show them to anybody.

Mr Evil said:

I hand draw my PCBs too. It's because PCBs are art!🙂 Plus it's about as DIY as you can get.

Agreed. Mr. Luthra has toughed it out the old macho way.

Also Kudos to his courage to show it to us, not everyone has that level of self esteem and confidence. We wish him the best in his project. People in my country have usually no idea what people in other countries have to go through to support an expensive hobby like this, the fact that you are trying to do what you can is commendable. Afterall this forum is not for only for experts in a peeing contest, it is also for regular folks who love audio.

Rajeev, I apologize on our friend's behalf if any comments seemed out of place,

kind regards,

Tekko said:No. Using perfboard and thin wire is as diy as you can get.😉

I sometimes wire all components p2p without perfboards, THATS as DIY as you can get. 😀

Etching and drilling PCBs, YUCK Perfboard as actually hardwire as you draw regular wire between components😉 Easier to get a nice looking layout too, also some components are desigend to work optimally when the board capacitances are present.

Perfboard as actually hardwire as you draw regular wire between components😉 Easier to get a nice looking layout too, also some components are desigend to work optimally when the board capacitances are present.

Perfboard as actually hardwire as you draw regular wire between components😉 Easier to get a nice looking layout too, also some components are desigend to work optimally when the board capacitances are present.

Perfboard as actually hardwire as you draw regular wire between components😉 Easier to get a nice looking layout too, also some components are desigend to work optimally when the board capacitances are present.New idea

I just had a new (?) idea.

Coat the whole board with some paint (?). Some film that can be scraped off easily. The film should not be brittle ( crack off in pieces ) or be too gooey like rubbery film . Possibly some sort of enamel paint ? I guess the thickness of the layer is very important. The layer should be coated , not painted.

Maybe apply a diluted layer of paint and spread it around and let the board stay on its edge for a few minutes for the excess paint to flow away . Then lay it flat to dry. Should form a fairly thin layer.

Maybe even acrylic paint - or nail polish . Methyl Acetate ( or nail polish remover) should be a good solvent. Will dry fast but not super fast. Even NC paint thinner will work. Will NC paint work ?

Scrape off the areas that need to be separated like guys do with a knife ( Xacto!) on "quick pcb's". The scraper tool should be as wide as the width that needs to be scraped off ( 0.5mm ?). One might need to make one by grinding it on a grinding wheel from some broken drill bits. The bit should be curved inward so that it lifts off the scraped material ( like a "C").

After that etch the board as usual.

Hope somebody tries it out. Let me see if I have time to experiment with this.

Cheers.

I just had a new (?) idea.

Coat the whole board with some paint (?). Some film that can be scraped off easily. The film should not be brittle ( crack off in pieces ) or be too gooey like rubbery film . Possibly some sort of enamel paint ? I guess the thickness of the layer is very important. The layer should be coated , not painted.

Maybe apply a diluted layer of paint and spread it around and let the board stay on its edge for a few minutes for the excess paint to flow away . Then lay it flat to dry. Should form a fairly thin layer.

Maybe even acrylic paint - or nail polish . Methyl Acetate ( or nail polish remover) should be a good solvent. Will dry fast but not super fast. Even NC paint thinner will work. Will NC paint work ?

Scrape off the areas that need to be separated like guys do with a knife ( Xacto!) on "quick pcb's". The scraper tool should be as wide as the width that needs to be scraped off ( 0.5mm ?). One might need to make one by grinding it on a grinding wheel from some broken drill bits. The bit should be curved inward so that it lifts off the scraped material ( like a "C").

After that etch the board as usual.

Hope somebody tries it out. Let me see if I have time to experiment with this.

Cheers.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Favorite High Power Output Transistor