Oy, a little congested in there sorry about that

Here you go

And thank you! Very gracious of you to offer doing this 🙂

Let me know if you need the other lines too, I only included the ones where the horn path notches

Yes, please get me the other lines too.

Thanks,

X

omg, what a nightmare. I actually feel bad for you right now, I really do.

** gently presses reply **

** gently presses reply **

Could you also mark the driver tap points and give the cross sectional areas at those points as well as the distance to the nearest purple lines?

If it's easy for you could you convert to cm? If not I can do it manually.

Also what is the exact internal height?

If it's easy for you could you convert to cm? If not I can do it manually.

Also what is the exact internal height?

Could you also mark the driver tap points and give the cross sectional areas at those points as well as the distance to the nearest purple lines?

If it's easy for you could you convert to cm? If not I can do it manually.

Also what is the exact internal height?

distances

areas

EDIT: found an error in my cross section, angle was wrong

next time I'll be staying in metric the whole time. I think I was just thinking about my cut sheet this time around

Last edited:

Measured from CAD areas

S1: 400.0 sq cm

S2: 524.59 sq cm

S3: 2073.71 sq cm

S4: 2247.29 sq cm

Measured from advanced centerline in CAD

L12: 33.58

L23: 287.25

L34: 32.13

Oh yeah, inner width is 37.5 exactly

S1: 400.0 sq cm

S2: 524.59 sq cm

S3: 2073.71 sq cm

S4: 2247.29 sq cm

Measured from advanced centerline in CAD

L12: 33.58

L23: 287.25

L34: 32.13

Oh yeah, inner width is 37.5 exactly

Comparison between initial "perfect" sim (grey) and sim based on actual CAD dimensions (black)

I think I got lucky here folks. The cinema4d method was definitely not exact, but with these roughs it appears to be pretty darn close. Hopefully factoring in human build error doesn't throw it off any more.

The dip at 100hz increased, while the response from 30hz - 80hz flattened out some. I'll take it. When the driver heats up and Re increases, it will help to flatten the 100hz dip (50% added to Re):

Now just curious to see what the akabakkers have to say about all of this craziness...

I think I got lucky here folks. The cinema4d method was definitely not exact, but with these roughs it appears to be pretty darn close. Hopefully factoring in human build error doesn't throw it off any more.

The dip at 100hz increased, while the response from 30hz - 80hz flattened out some. I'll take it. When the driver heats up and Re increases, it will help to flatten the 100hz dip (50% added to Re):

Now just curious to see what the akabakkers have to say about all of this craziness...

Huzzah... I have been looking at the screen too long!

I am all mixed up, I had L12 & L34 values switched around..

I was like... how the heck is L34 < L12?? Doh

Response is right on the money! You can't even see that grey comparison line!

😀 😀 😀

CAD measured hornresp parameters (fixed)

I am all mixed up, I had L12 & L34 values switched around..

I was like... how the heck is L34 < L12?? Doh

Response is right on the money! You can't even see that grey comparison line!

😀 😀 😀

CAD measured hornresp parameters (fixed)

Already thinking about mids

I have these two Faital 8FE200's laying here not doing anything. I think they might be pretty underpowered compared to this sub (probably an understatement), but my next step is seeing if I can't get something good out of a vented / front loaded horn hybrid enclosure with some driver & a horizontal/vertical dimension of 39x11. Obviously the pic above is just some kind of whack mockup to see what it might look like.

I just wanna make a bunch of horns. Horns for everything, all the time.

Been eyeing jbells HS12's, specifically this dual 10" configuration mentioned here:

http://www.diyaudio.com/forums/pa-systems/160911-jbell-pa-top.html#post2078495

I've never made a FLH, but with hornresp fresh on the mind it's not looking nearly as difficult.

Theoretically I would be able to run the sub 1ch @ 2ohm 1200W from JL HD1200, midbass on 2ch bridged of the JL HD600 @ 2/4ohm 300W, and one of my 1.4" CD horns on the other 2ch bridged @ 8ohm 150W. Crossover points ideally at 100hz & 1300hz.

I have these two Faital 8FE200's laying here not doing anything. I think they might be pretty underpowered compared to this sub (probably an understatement), but my next step is seeing if I can't get something good out of a vented / front loaded horn hybrid enclosure with some driver & a horizontal/vertical dimension of 39x11. Obviously the pic above is just some kind of whack mockup to see what it might look like.

I just wanna make a bunch of horns. Horns for everything, all the time.

Been eyeing jbells HS12's, specifically this dual 10" configuration mentioned here:

http://www.diyaudio.com/forums/pa-systems/160911-jbell-pa-top.html#post2078495

I've never made a FLH, but with hornresp fresh on the mind it's not looking nearly as difficult.

Theoretically I would be able to run the sub 1ch @ 2ohm 1200W from JL HD1200, midbass on 2ch bridged of the JL HD600 @ 2/4ohm 300W, and one of my 1.4" CD horns on the other 2ch bridged @ 8ohm 150W. Crossover points ideally at 100hz & 1300hz.

Last edited:

Jennygirl,

Thanks for all those dims. Yes, it does look like a lot of numbers. I am at 27 segments and wonder if it may be better to simplify the hairpin turns to four 90 deg turns. That is what I normally do and it captures that big area expansion to the vertex of each corner better. Plus but will reduce the number of nodes used. Not that I am hitting the limit as AkAbak can handle 52 nodes in any one system.

A few questions:

1. Is this a one driver or two driver system?

2. What is the internal width?

3. Do you plan to use some damping it stuffing anywhere like maybe the first section or two?

Thanks,

X

Btw, cool that you like horns. I have tried almost exactly what you did by putting a mid in very small folded tapped horn and it sounds terrible. You get reverberations and all the higher freq get muffled due to the low pass nature of the turns. If you want a great sounding mid horn - try a tractrix. I recently built one for a PRV 5MR450NDY (5 in 95dB mid with 250 watt power handling). The tractrix sounds great - very nice and super low harmonic distortion. I think a similar horn can be made for an 8in mid. It may be kind of big but sounds excellent. More info here: http://www.diyaudio.com/forums/full-range/259293-prv-5mr450-ndy-fast-applications.html. I used foam core but you could use bendy plywood or even foam core and fiberglass it if you want more durability. Info on calculating the horn profile is in link in thread to Volvtreter's spreadsheet. Also, I think you could just use the horn I designed for the 5in driver and put the 8in behind it as you are looking for mids and not full range. I can sim that in AkAbak too. It all probably go up to 4k or 5khz. The SPL sensitivity will be insane - in the 110dB range. If you use my design, a 2d cut template is provided in the thread (you can scale that up or down and it works - I scaled down to 0.7x and it works great). The 2d template is the key to making this and required me to model the horn in 3d then use sheet metal tools in Solidworks to unroll it to a flat pattern. That pattern, when anchored at the throat and mouth boundary conditions force a flexible sheet to form the tractrix automatically.

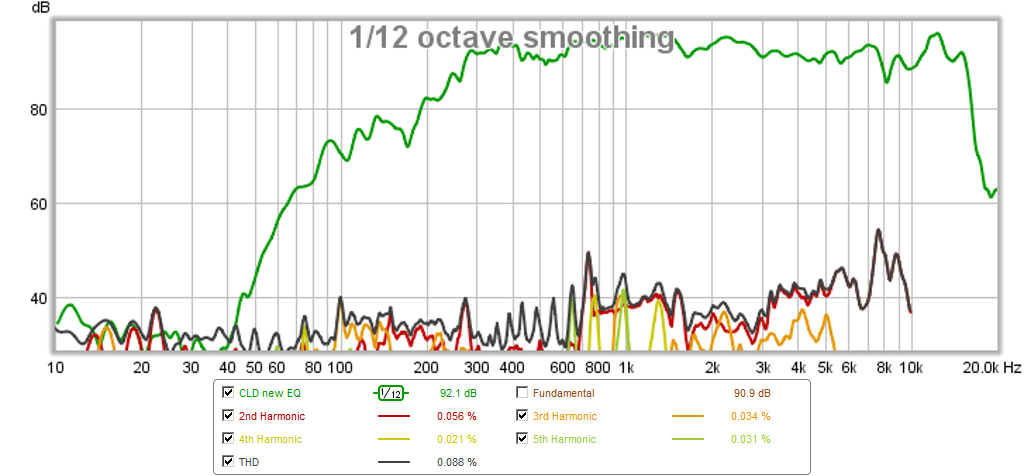

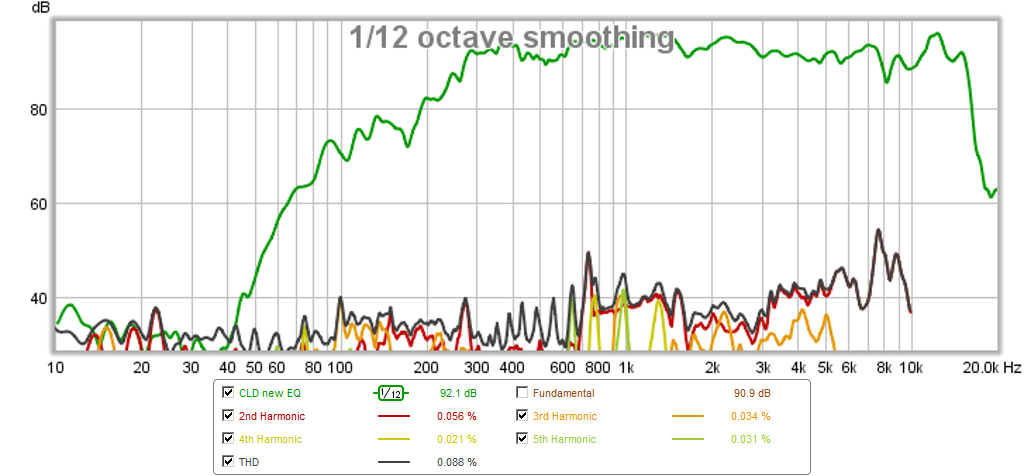

Here is the type of performance I got with the PRV driver in a 28in wide x 22in long tractrix.

Thanks for all those dims. Yes, it does look like a lot of numbers. I am at 27 segments and wonder if it may be better to simplify the hairpin turns to four 90 deg turns. That is what I normally do and it captures that big area expansion to the vertex of each corner better. Plus but will reduce the number of nodes used. Not that I am hitting the limit as AkAbak can handle 52 nodes in any one system.

A few questions:

1. Is this a one driver or two driver system?

2. What is the internal width?

3. Do you plan to use some damping it stuffing anywhere like maybe the first section or two?

Thanks,

X

Btw, cool that you like horns. I have tried almost exactly what you did by putting a mid in very small folded tapped horn and it sounds terrible. You get reverberations and all the higher freq get muffled due to the low pass nature of the turns. If you want a great sounding mid horn - try a tractrix. I recently built one for a PRV 5MR450NDY (5 in 95dB mid with 250 watt power handling). The tractrix sounds great - very nice and super low harmonic distortion. I think a similar horn can be made for an 8in mid. It may be kind of big but sounds excellent. More info here: http://www.diyaudio.com/forums/full-range/259293-prv-5mr450-ndy-fast-applications.html. I used foam core but you could use bendy plywood or even foam core and fiberglass it if you want more durability. Info on calculating the horn profile is in link in thread to Volvtreter's spreadsheet. Also, I think you could just use the horn I designed for the 5in driver and put the 8in behind it as you are looking for mids and not full range. I can sim that in AkAbak too. It all probably go up to 4k or 5khz. The SPL sensitivity will be insane - in the 110dB range. If you use my design, a 2d cut template is provided in the thread (you can scale that up or down and it works - I scaled down to 0.7x and it works great). The 2d template is the key to making this and required me to model the horn in 3d then use sheet metal tools in Solidworks to unroll it to a flat pattern. That pattern, when anchored at the throat and mouth boundary conditions force a flexible sheet to form the tractrix automatically.

Here is the type of performance I got with the PRV driver in a 28in wide x 22in long tractrix.

Last edited:

Hi xrk- once again I appreciate your efforts. It is a two driver system, internal width of 37.5", and no I was not planning on using damping. I didn't know THs ever used damping in fact. Let me know if you think it would be a good idea- it is still up in the air as of now, but not for long.

Yeah horns are the coolest.. Free dB! Well not really I guess when you factor in size, but I am all about low power max efficiency mobile systems so the horn is a natural fit!

Wow that tractrix is really cool. I am so down for something crazy like that. Makes a ton of sense and looks really weird/cool to boot.

How big would it have to be to cover the gamut of midrange frequencies I would need it for (100hz seems to be pretty important with the subs). My top cd horns sound great with anything above 1200 where I was crossing them in the existing 2 way setup.

I guess I could go as wide as 39". Ridiculous looking is not only okay but basically preferred 😉 ...especially with such high efficiency benefit.

Thanks for the recommendation, it sounds and looks like a wonderful idea

Yeah horns are the coolest.. Free dB! Well not really I guess when you factor in size, but I am all about low power max efficiency mobile systems so the horn is a natural fit!

Wow that tractrix is really cool. I am so down for something crazy like that. Makes a ton of sense and looks really weird/cool to boot.

How big would it have to be to cover the gamut of midrange frequencies I would need it for (100hz seems to be pretty important with the subs). My top cd horns sound great with anything above 1200 where I was crossing them in the existing 2 way setup.

I guess I could go as wide as 39". Ridiculous looking is not only okay but basically preferred 😉 ...especially with such high efficiency benefit.

Thanks for the recommendation, it sounds and looks like a wonderful idea

Hi jennygirl,

It's been a while since I have thought about this subject, but for a nice midrange horn for the Eminence Beta-12A-2 take a look here, Posts #226/234/245/249/255/267 (290 🙂) /304/333/336:

http://www.diyaudio.com/forums/subwoofers/213685-bass-my-soldier-24.html

epa (Erik) designed it and did the CAD work. Build pictures start @ Post #332. Finished picture in Post #346.

It does need an additional high frequency horn, e.g.: Post #233.

Regards,

It's been a while since I have thought about this subject, but for a nice midrange horn for the Eminence Beta-12A-2 take a look here, Posts #226/234/245/249/255/267 (290 🙂) /304/333/336:

http://www.diyaudio.com/forums/subwoofers/213685-bass-my-soldier-24.html

epa (Erik) designed it and did the CAD work. Build pictures start @ Post #332. Finished picture in Post #346.

It does need an additional high frequency horn, e.g.: Post #233.

Regards,

So many options. It will once again be tough to decide. Ultimately it will be about frequency response, stacking it right on top of the sub is as well important. Ease of build, too.

So far the HS12 with beta12a looks like the sure fire win, but options are inspiring me- especially xrk's. Thanks for the rec's.

Once I get this sub done it'll be time to finalize mid horn. I can already tell part of me wants it to be a horn I designed myself.

So far the HS12 with beta12a looks like the sure fire win, but options are inspiring me- especially xrk's. Thanks for the rec's.

Once I get this sub done it'll be time to finalize mid horn. I can already tell part of me wants it to be a horn I designed myself.

Last edited:

Hi jennygirl,

Have you looked into the unity/synergy horns?

Regards,

No I have not, but I am now 🙂

Hi jennygirl,

The unity horn patent is US 6,411,718 B1. The synergy horn application is US 2009/0136072 A1.

bwaslo did a wonderful job w/ a build and design spreadsheet:

DIY Synergy/Unity spreadsheet

and a general index on the subject:

Index of DIY Synergy and Unity Horns

Regards,

The unity horn patent is US 6,411,718 B1. The synergy horn application is US 2009/0136072 A1.

bwaslo did a wonderful job w/ a build and design spreadsheet:

DIY Synergy/Unity spreadsheet

and a general index on the subject:

Index of DIY Synergy and Unity Horns

Regards,

I think this is about as good as I could do in 3 minutes with the 2 8FE200's in a vented FLH that matches the S3 of the mockup in post 189.

Honestly, seems rather doable. I might need to lower the tuning slightly to better match the 100hz dip in the subs. But it is looking promising to me, what do you think?

It's certainly not ideal or the highest efficiency, but I have everything I need besides a sheet of plywood. Jbell's HS tops are proven to have a great sound to them, and this is very closely related.

39x11 front box dimension, 4x 2" cutout holes deep in the throat

Honestly, seems rather doable. I might need to lower the tuning slightly to better match the 100hz dip in the subs. But it is looking promising to me, what do you think?

It's certainly not ideal or the highest efficiency, but I have everything I need besides a sheet of plywood. Jbell's HS tops are proven to have a great sound to them, and this is very closely related.

39x11 front box dimension, 4x 2" cutout holes deep in the throat

what you have modelled is *not* 4x 2" coutout holes deep in the throat though. horn loading the port output WILL have an affect on the overall sound.

what you have modelled is *not* 4x 2" coutout holes deep in the throat though. horn loading the port output WILL have an affect on the overall sound.

I guess jbell described the effect as "feedback".

Sorry I meant 4x 3" cutout ports oopsie

I'm just saying, what you have modelled does not include the the ports *inside* the horn, but rather on the outside of the horn (easily done). setting the ports back in the horn will likely affect response shape, but I'm terrible at top design so I couldnt tell you how.

I kind of missed a couple of pages of responses.... what was your max cabinet dimensions again? I noticed your most recent sim is like... 450 liters, which is fairly large.

I kind of missed a couple of pages of responses.... what was your max cabinet dimensions again? I noticed your most recent sim is like... 450 liters, which is fairly large.

- Home

- Loudspeakers

- Subwoofers

- FaitalPRO 15HP1060 vs 3015LF for tapped horn?