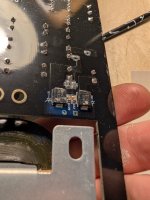

I've got an Allo Shanti dual power supply with a 3amp (dirty) and 1amp (clean) side. The Allo Digione Signature has been giving me grief, and I thought it might be this power supply. I opened up and found some oily residue in there that should not be in there. It's stored pretty far behind stuff on the third shelf down of the hifi rack. I did some poking around, and it's likely a failed capacitor, but I'd love some second opinions before I buy parts and start down this rabbit hole. Any advice or wisdom? thanks!

In one of the pics, you can see my finger smudge on the pcb for reference.

In one of the pics, you can see my finger smudge on the pcb for reference.

Attachments

A few more things to report. On this plastic electrical protector on the bottom of the PCB two devices look like they got real hot at some point. I was able to narrow it down to these two components: I think they are Schotty diodes, chatgpt says "Schottky Barrier Rectifiers, specifically the B340A model." Are they supposed to get super hot?

I got a usb load tester and ran both the outputs of the dual power supply up to their rated amperage: 1.0amps for the "clean side" and 3.0 amps for the "dirty side." On each side, one of the transistors got super hot, too hot to touch. I'm borrowing a FLIR camera later today to see if there are any other components that get oddly hot they are Q14 and Q11.

Do you think this is a lost cause? Or are there any other steps I can take for trouble shooting this power supply?

I got a usb load tester and ran both the outputs of the dual power supply up to their rated amperage: 1.0amps for the "clean side" and 3.0 amps for the "dirty side." On each side, one of the transistors got super hot, too hot to touch. I'm borrowing a FLIR camera later today to see if there are any other components that get oddly hot they are Q14 and Q11.

Do you think this is a lost cause? Or are there any other steps I can take for trouble shooting this power supply?

Attachments

Last edited:

Working from pictures is really difficult at the best of times 🙂

I would first vacuum the board on both sides with a soft brush. If its still grubby then I would, and this isn't a recommendation if you have never done this before, give it a good wash in hot soapy water (not the transformer though). It would come up like new.

Ideally you should fix the fault first and that means measurement and diagnostics. Nothing obvious shows up in the pictures like bulged caps etc.

I would first vacuum the board on both sides with a soft brush. If its still grubby then I would, and this isn't a recommendation if you have never done this before, give it a good wash in hot soapy water (not the transformer though). It would come up like new.

I actually had cause to wash a PCB today, OK so it was only a remote control but it was a good example.

Having rinsed the PCB I added a few drops of ordinary washing up liquid poured neat onto the PCB. Soft brush to clean both sides, rinse, shake, pat dry with a paper towel and dry on a radiator.

Having rinsed the PCB I added a few drops of ordinary washing up liquid poured neat onto the PCB. Soft brush to clean both sides, rinse, shake, pat dry with a paper towel and dry on a radiator.

Ideally you should fix the fault first and that means measurement and diagnostics. Nothing obvious shows up in the pictures like bulged caps etc.

Washing a PCB, that's a crazy idea! But there ya go. I don't have any experience in that, I'd feel more comfortable wiping the thing down with some little cotton q-tips and stuff like that I think.

How about this pic of filth? Anything? There was some other white schmootz on this trimpot.

How about this pic of filth? Anything? There was some other white schmootz on this trimpot.

I think the 3.3F/2.7V might be slightly bulging. I've seen those super hi value caps fail a bit more frequently than regulars. Maybe check it first. The white goo could be electrolyte from it.

I used to do just that and quite often in the large service dept where I worked. Many a TV or VCR panel has had that treatment 😉Washing a PCB, that's a crazy idea! But there ya go.

Its hard to say just what all that is in your picture and where it originated. Airborne dirt and dust perhaps of the casing is open with ventilation slots. I've seen far far worse though.

I think the 3.3F/2.7V might be slightly bulging.

Can you see any bulging in the first picture in the thread... nothing obvious stood out to me 🙂

I agree with some board washing and let it fully dry. The 3.3F 2.7V capacitor will not likely see enough charging current to ever vent. It is likely used as backup memory power when the device is off.

Hi Mike,

Yes, I see a slight bulge if you look along the vent line from the side to the center. No idea if that is an actual problem or not.

Hi Karl,

Yes, I wash PCBs occasionally. Some parts have to be removed or sealed (trimmer caps, pots, relays). Then a heat gun on low and far away enough so you don't cook anything, then allow to dry overnight. I'll hit it with a zero residue cleaner after the heat gun and it cools a bit. Washing PCBs means you have to be observant and careful.

Yes, I see a slight bulge if you look along the vent line from the side to the center. No idea if that is an actual problem or not.

Hi Karl,

Yes, I wash PCBs occasionally. Some parts have to be removed or sealed (trimmer caps, pots, relays). Then a heat gun on low and far away enough so you don't cook anything, then allow to dry overnight. I'll hit it with a zero residue cleaner after the heat gun and it cools a bit. Washing PCBs means you have to be observant and careful.

Yes, I can see any aqueous solution containing salt as being more than a little bad for just about everything!

You've got to rinse everything using distilled water or a zero residue cleaner that doesn't have an appetite for anything on the board. That means you often have to remove some parts. Remember most capacitors use a rubber seal, maybe not the newer ones. Sometimes fluids can wick up inside old transistors.

You've got to rinse everything using distilled water or a zero residue cleaner that doesn't have an appetite for anything on the board. That means you often have to remove some parts. Remember most capacitors use a rubber seal, maybe not the newer ones. Sometimes fluids can wick up inside old transistors.

- Home

- Design & Build

- Construction Tips

- failed capacitor?