Two part epoxy. Would it stay put and be strong enough for a table surface? I want to avoid using screws unless I really have to.

Would it stay put and be strong enough for a table surface?

It depends, what are you trying to accomplish?

Mike

Check with the manufacturer first but I use this for most all my veneering no matter what the stuff that needs to be glued down is. Darryl Who owns the company who makes it is a great and knowledgeable guy.

https://www.vacupress.com/product/unibond-800-1-gallon-liquid-resin/

Evan

https://www.vacupress.com/product/unibond-800-1-gallon-liquid-resin/

Evan

I've bonded metal to plywood with PL Construction Adhesive. The PL has to be spread evenly with a flat edge. Press the two surfaces together.

Everything is in the prep of the metal. Why not use the same contact cement they use for Formica?

Two part epoxy is incredibly strong when applied correctly, and works great for metal and plywood. As long as the bonding area isn't too small, it will likely last forever.

As Conrad implied, if the metal surface is polished and not obsessively degreased and dried, the Epoxy adherence won't be great, I suggest sandblasting it and then proper degreasing, at least with some clean solvent but even better with some Industrial detergent, which will leave no residue.

As also suggested, solvent based contact cement might work better simply because of 2 factors: solvent dissolves any residual oils (even touching surface with bare hand will contaminate it) and being slightly flexible, will resist possible bending and impact better.

As also suggested, solvent based contact cement might work better simply because of 2 factors: solvent dissolves any residual oils (even touching surface with bare hand will contaminate it) and being slightly flexible, will resist possible bending and impact better.

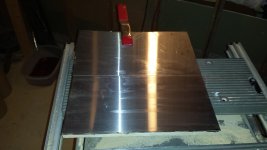

Sorry for not covering everything. The steel was never used it still had the plastic on. there are no contaminants other than prints. I could also give it a wipe with disc brake rotor cleaner. I think I might try the cement. Im pretty confident it will be on there for good. Time as always will tell.

I think that construction adhesive like Liquid Nails or RTV Silicone would be a better choice for that application than Epoxy, and less expensive too.

Mike

Mike

I second epoxy. My experience doesn't agree with the comments about "obsessively clean". Clean yes, but no need to go overboard.

Most important prep for epoxy on steel is sanding with #80 grit. (Also being clean but that was already mentioned).

Also there are some epoxies especially formulated for dissimilar material joins, e.g. West G-flex. Follow instructions and joint will last forever.

Also there are some epoxies especially formulated for dissimilar material joins, e.g. West G-flex. Follow instructions and joint will last forever.

Its meant for an audio base that will have an amp on it, or other device. So it wont be subject to any negative g's that might potentially pull and tear the two surfaces apart upon re entry.

Check on the 80 grit. I planned on roughing up the two surfaces before any permanent or non permanent bonding takes place.

Does the cement dry as the name would imply? I remember some stuff I was in contact with having more of a hard rubbery like feel to it. It wasnt sillycone, no mistaking. I suspect there could be different types. Since it is audio related vibration cancellation will be my friend here.

Epoxy is more fun to play with. I'm really back on the fence here now fella's.

Check on the 80 grit. I planned on roughing up the two surfaces before any permanent or non permanent bonding takes place.

Does the cement dry as the name would imply? I remember some stuff I was in contact with having more of a hard rubbery like feel to it. It wasnt sillycone, no mistaking. I suspect there could be different types. Since it is audio related vibration cancellation will be my friend here.

Epoxy is more fun to play with. I'm really back on the fence here now fella's.

Oh yeah, if I use a primer wouldnt that mean its relying on the ability of the primer to hold on rather than the adhesive itself? Not too sure if I should use it but have plenty of it.

Well, think of a primer as a chemical modification to the surface of the stainless which serves to make it chemically compatible with the adhesives.

This isn't a high performance joint, however. I'd still be doing a good bit of research:

http://www.euro-inox.org/pdf/map/Adhesive_bonding_EN.pdf

This isn't a high performance joint, however. I'd still be doing a good bit of research:

http://www.euro-inox.org/pdf/map/Adhesive_bonding_EN.pdf

Here's a little bit about gflex epoxy, it has a little table showing prep work:

WEST SYSTEM - Projects - WEST SYSTEM launches G/flex Epoxy

Most manufacturers have similar products. Note that this is not "just" epoxy it has special additives. I only recommend because I have used it, primarily for aluminum to carbon fiber, but also for steel. Is this stainless steel? That is harder. But if its not a structural bond many adhesives will work.

If this is important to you then experiment on a trial piece first.

WEST SYSTEM - Projects - WEST SYSTEM launches G/flex Epoxy

Most manufacturers have similar products. Note that this is not "just" epoxy it has special additives. I only recommend because I have used it, primarily for aluminum to carbon fiber, but also for steel. Is this stainless steel? That is harder. But if its not a structural bond many adhesives will work.

If this is important to you then experiment on a trial piece first.

- Status

- Not open for further replies.

- Home

- Design & Build

- Construction Tips

- epoxy for bonding sheet metal to plywood?