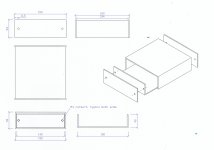

I was looking for suitable enclosures for a couple of projects that I was working on, I needed four of different sizes, the commercially made ones that I had short-listed were a bit too much for the available budget, so I got thinking how I could build something like I wanted myself, I ended up with some readily available off the shelf extrusions and AutoCAD and came up with this:

The Concept

The Concept

Attachments

Small box

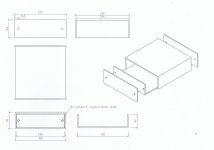

The small box shown here is for a Rod Elliott RIAA pre-amplifier, the circuit board complete ready for standoffs and wiring.

This box is ~100mm (4”) square x 50mm high

The length of the outer casings are purposely made longer than the width of the inner channel chassis so that when you tighten the screws, it clamps together. The inner channel chassis is the same extrusion as the case, with one side sawn off.

The small box shown here is for a Rod Elliott RIAA pre-amplifier, the circuit board complete ready for standoffs and wiring.

This box is ~100mm (4”) square x 50mm high

The length of the outer casings are purposely made longer than the width of the inner channel chassis so that when you tighten the screws, it clamps together. The inner channel chassis is the same extrusion as the case, with one side sawn off.

Attachments

Bit more progress

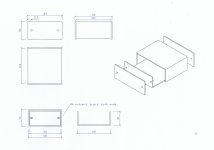

These are the other three;

1. An old project of mine an Elektor Class A headphone amp that I build many moons ago, (circa 1983!) its a perfect fit in the new chassis, note the tags left on the back to heatsink the output transistors and the large hole in the faceplate to recess the control knob. I plan some hidden LED's in there to light up around the knob

2. Is a Tripath amp board sitting in its new chassis, the board is missing a few parts while it's being upgraded.

3. ls a passive pre-amp / input selector, I plan a Lightspeed Attenuator for this one!

The plan is to get the main bodies powdercoated (don't know what colour yet) and fix the backs and faces with some M4 stainless steel socket head cap screws

I'll post more pictures as the project progresses

These are the other three;

1. An old project of mine an Elektor Class A headphone amp that I build many moons ago, (circa 1983!) its a perfect fit in the new chassis, note the tags left on the back to heatsink the output transistors and the large hole in the faceplate to recess the control knob. I plan some hidden LED's in there to light up around the knob

2. Is a Tripath amp board sitting in its new chassis, the board is missing a few parts while it's being upgraded.

3. ls a passive pre-amp / input selector, I plan a Lightspeed Attenuator for this one!

The plan is to get the main bodies powdercoated (don't know what colour yet) and fix the backs and faces with some M4 stainless steel socket head cap screws

I'll post more pictures as the project progresses

Attachments

Very Nice work Audio0 🙂 Where did you get the extrusions? and roughly how much were they? I'm going to need a case for my B1 (once I get some momentum on it).

Tony.

Tony.

Aluminium supply

Hi Tony,

The extrusions, 150 x 50 x 3mm and 100 x 50 x 3mm I bought from a local alloy supplier (Capral) The 150 x 50 x 3 was about A$25/M and the smaller one, 100 x 50 x 3 was about A$18/M

The 3mm sheet I had laying around, I think you would pay about A$40/M² for 3mm sheet

Although I planned to use nutserts, I just drilled and tapped the extrusion instead.

Hope this helps.

Cheers.. Steve

Hi Tony,

The extrusions, 150 x 50 x 3mm and 100 x 50 x 3mm I bought from a local alloy supplier (Capral) The 150 x 50 x 3 was about A$25/M and the smaller one, 100 x 50 x 3 was about A$18/M

The 3mm sheet I had laying around, I think you would pay about A$40/M² for 3mm sheet

Although I planned to use nutserts, I just drilled and tapped the extrusion instead.

Hope this helps.

Cheers.. Steve

Well done Steve. Your boxes have the same configuration as the NAIM NAIT I & II that i once owned.

dave

dave

Member

Joined 2002

Hello audi0,

I like your ingenuity!

I've CAD'd up some boxes for a Firstwatt F5. The design is pretty simple and uses the Conrad heatsinks as the main support structure. Once I finalise the design, I see what price a local metal fabricator will cut up the aluminum plate for me.

Cheers,

alex

I like your ingenuity!

I've CAD'd up some boxes for a Firstwatt F5. The design is pretty simple and uses the Conrad heatsinks as the main support structure. Once I finalise the design, I see what price a local metal fabricator will cut up the aluminum plate for me.

Cheers,

alex

Heatsinks

Hi Alex,

Actually I have a passively cooled audio computer in very early stages of construction, I was thinking of using Altronics diecast heatsinks (H05450) as part of the structure, great minds....

Hello audi0,

I like your ingenuity!

I've CAD'd up some boxes for a Firstwatt F5. The design is pretty simple and uses the Conrad heatsinks as the main support structure. Once I finalise the design, I see what price a local metal fabricator will cut up the aluminum plate for me.

Cheers,

alex

Hi Alex,

Actually I have a passively cooled audio computer in very early stages of construction, I was thinking of using Altronics diecast heatsinks (H05450) as part of the structure, great minds....

Conrad

Hey Alex,

I just checked the Conrad web site, I think the Altronics item might be a Conrad product

Hello audi0,

I like your ingenuity!

I've CAD'd up some boxes for a Firstwatt F5. The design is pretty simple and uses the Conrad heatsinks as the main support structure. Once I finalise the design, I see what price a local metal fabricator will cut up the aluminum plate for me.

Cheers,

alex

Hey Alex,

I just checked the Conrad web site, I think the Altronics item might be a Conrad product

Thanks Steve!! Much cheaper than buying cabinets, and might I say a Nicer result to boot! 🙂

Tony.

Tony.

Hey Alex,

I just checked the Conrad web site, I think the Altronics item might be a Conrad product

Yeah, I believe Altronics do stock a few of the Conrad heat sinks.

I bought 4x MF35-151.5 and the shipping to Perth was only $12! The heat sinks look great, and all reports on DIYA are good for quality and customer service.

Cheers,

alex

- Status

- Not open for further replies.

- Home

- Design & Build

- Construction Tips

- Enclosure construction