How tightly should I be packing wool into my enclosure?

I have this R15 cut in half (approx 2") and stapled to all the sides of the enclosure. I am leaving area behind the woofer to the port open with no packing material between those two.

I started packing in wool everywhere else inside the enclosure and quickly realized that I can lightly stuff it in there or I can jam it in there and fit 10x times as much inside.

I assume there is a happy medium here....? Should it just not be compressed further than how it comes out of the package? Should it be fluffed beyond how compressed it comes (I feel like it comes pretty tightly packed as it)

I have this R15 cut in half (approx 2") and stapled to all the sides of the enclosure. I am leaving area behind the woofer to the port open with no packing material between those two.

I started packing in wool everywhere else inside the enclosure and quickly realized that I can lightly stuff it in there or I can jam it in there and fit 10x times as much inside.

I assume there is a happy medium here....? Should it just not be compressed further than how it comes out of the package? Should it be fluffed beyond how compressed it comes (I feel like it comes pretty tightly packed as it)

Attachments

The quantity of the wall lining in a reflex enclosure could come down to a matter of taste. Too much absorption may take the life out of the reproduction.

A halfway house is partial lagging where one interior face of the enclosure is covered with thick felt or wadding and the opposite face is left bare.

I would line the walls with the lagging as it comes out of the package and allow it to expand to its natural density over time.

A halfway house is partial lagging where one interior face of the enclosure is covered with thick felt or wadding and the opposite face is left bare.

I would line the walls with the lagging as it comes out of the package and allow it to expand to its natural density over time.

Last edited:

Rockwool. Stiff fiberglass. I prefer that in TL designs and for room sound treatment. My go to for TL designs is 1-3/4” rockwool on the walls and then fiberglass fill in the top section. I do a totally extremely scientific test by sticking one ear in the woofer hole and listen, if I hear mostly nothing then I don’t add more stuffing.

Back to the original question… go by ear. If the box seems to ring or the midrange is smeared then stuff a little more. If kick drums go boom instead of bump add more. If it sounds stuffy (it will actually sound stuffy) or dead, then un-stuff the box. If the kick drum goes bmp instead of bump then take some out. It looks to me like you have a good amount of stuffing, try it for a while. Listening to jazz records with a lot of plucked bass is a great way to check the woofer stuffing.

Also, adding a lot of stuffing to a closed box will increase the apparent box size. I don’t know the calculations for this, I just know it works.

Good luck!

Back to the original question… go by ear. If the box seems to ring or the midrange is smeared then stuff a little more. If kick drums go boom instead of bump add more. If it sounds stuffy (it will actually sound stuffy) or dead, then un-stuff the box. If the kick drum goes bmp instead of bump then take some out. It looks to me like you have a good amount of stuffing, try it for a while. Listening to jazz records with a lot of plucked bass is a great way to check the woofer stuffing.

Also, adding a lot of stuffing to a closed box will increase the apparent box size. I don’t know the calculations for this, I just know it works.

Good luck!

It depends if the "drive unit + box" has been designed for minimal or heavy stuffing.How tightly should I be packing wool into my enclosure?

If you stuff with rockwool, fibreglass or long-haired wool from the backs of Yorkshire sheep, stuffing so adiabatic conditions hold (about the consistency of a cushion) not only increases the apparent box size but reduces yucky midrange reflection colourations from reflections & resonances in the box.

I like to design boxes that do this but you have to account for the losses due to the stuffing if you want the same LF.

You are doing the right thing by ensuring an open path between the LF unit and the port.

Cheapo BAF, polyester stuffing isn't as good.

A ported enclosure doesn't need internal damping. Only the wall resonances should be treated by absorbing panels. Same material as dampening car doors etc. In the past bitumenous felt was used, today there might be more modern materials.

That depends on the passband range of the woofer. If the enclosure resonances of opposing walls are in the woofer passband (usually with 2-way midwoofers) you need to take care so they don't exit through the loudspeaker diaphragm and through the port. One possible solution is damping material.A ported enclosure doesn't need internal damping.

Edit:

I did some measurements here:

https://www.diyaudio.com/community/...rbers-and-port-geometries.388264/post-7695049

If it was operating under pure Helmholtz conditions that would be true. Unfortunately, most boxes have some degree of internal eigenmodes which can disrupt the response characteristic, so assuming driver, vent etc. are optimally positioned relative to those, a modest amount of damping (such as GM indicates above) is usually needed. If you don't want to measure, the old click test can help with that.A ported enclosure doesn't need internal damping. Only the wall resonances should be treated by absorbing panels. Same material as dampening car doors etc. In the past bitumenous felt was used, today there might be more modern materials.

This is a misconception that pops up from time to time. The car door stuff and equal materials actually do nothing for the internal acoustics, nor do they damp panel resonances that well if put onto enclosure walls instead of between constructive layers.Same material as dampening car doors etc. In the past bitumenous felt was used, today there might be more modern materials.

Can you elaborate on this please?Burst decay plots from measurements on both woofer and port close range tell a lot about the right amount of stuffing.

What should I be looking for in the Hurst decay plot?

A reasonably clean decay spectrum down to -25 /-30dB. In the plot attached you can witness that resonances are all over the place (the ridges in the front). But in this case, they are quite low in amplitude and don't show up in the frequency response at period = 0. So 'this case' is damped OK.

I can't find a plot with severe resonances right now, have no access to my complete measurement library.

I might add the response plot and the impedance plot give it away too. Any hiccups in an otherwise quite gradual changing line gives it away too.

I can't find a plot with severe resonances right now, have no access to my complete measurement library.

I might add the response plot and the impedance plot give it away too. Any hiccups in an otherwise quite gradual changing line gives it away too.

How tightly should I be packing wool into my enclosure?

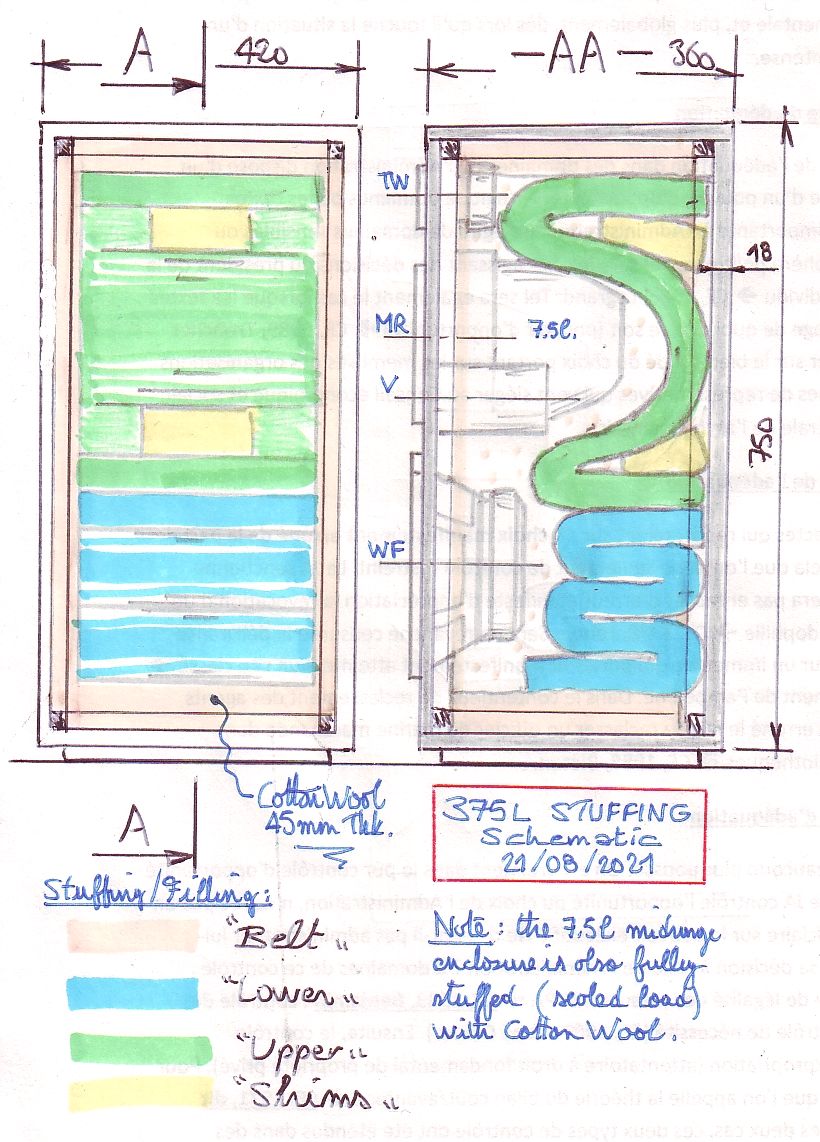

I use Cotton wool in rather good quantity - that said, the Woofer and his port must remain reasonably clear from damping, I mean they must not be blocked ! See the drawing at the bottom of the post... 😉

T

Got it, this is very helpful

So the idea is to add stuffing until the burst decay looks good but don't just keep adding it.

So the idea is to add stuffing until the burst decay looks good but don't just keep adding it.

In the plot attached

Nice to see one with periods instead of sec as the depth axis. A much better format for examining ringing.

Q are displayed in the same manner, and you are looking for a series of “parallel” lines as the DUT rings down.

dave

I use Cotton wool in rather good quantity

Looks an aweful lot like the Bonded Logic UltraTouch recycled cotton i use.

dave

...If you stuff with rockwool, fibreglass or long-haired wool from the backs of Yorkshire sheep, stuffing so adiabatic conditions hold (about the consistency of a cushion) not only increases the apparent box size but reduces yucky midrange reflection colourations from reflections & resonances in the box...

As a pedant, I feel duty bound to correct your use of the term "adiabatic" - it should read "isothermal" (i.e. a process where temperature doesn't change, which is the effect of the stuffing acting as a heat sink).

No, adiabatic is correct, there isn't any time to exchange with the environment. Because the pressure changes in audio are that small that you do not think that the temperature change isn't that they do not happen. Only it is rather difficult to measure picodegree (or less) changes at several Hz.

Oh dear - another argument. The air in the unstuffed box reacts to changes in volume (the cone moving in and out) by changing pressure, and these changes result in changes in temperature, which act to exaggerate the pressure changes. That describes an adiabatic process.

Thus, the air acts as a spring.

Adding stuffing has the effect of acting as a distributed heatsink, such that the temperature changes are minimised, and the pressure changes are therefore reduced such that the relationship PV = constant is approached (which is true for an isothermal process). The reduction in the pressure changes is the equivalent of the compliance of the air-spring being increased. This reduces the frequency of resonance defined by the cone mass and the total compliance experienced by the cone.

edit - typo

Thus, the air acts as a spring.

Adding stuffing has the effect of acting as a distributed heatsink, such that the temperature changes are minimised, and the pressure changes are therefore reduced such that the relationship PV = constant is approached (which is true for an isothermal process). The reduction in the pressure changes is the equivalent of the compliance of the air-spring being increased. This reduces the frequency of resonance defined by the cone mass and the total compliance experienced by the cone.

edit - typo

- Home

- Loudspeakers

- Multi-Way

- Elementary Noob Question of the Day: How tightly should you pack wool in an enclosure?