Colleagues, ask for advice.

Who else was producing this driver?

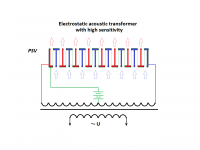

Emitter on the principle of radiation similar to Air Motion Transformer Hail (AMT).

But used an electrostatic "motor".

In principle, there are two possibilities.

1. The stators plate sound goes along them, as well as at traditional Hale.

2. The stators rods,sound goes through them, in the space between the rods.

Expected strongly increased sensitivity.

Conductor width and depth of the "folds" principle is not limited to the distance between the magnets, like the AMT.

The stator is located at an optimum distance from the film and can be very thin.

Thanks !

Who else was producing this driver?

Emitter on the principle of radiation similar to Air Motion Transformer Hail (AMT).

But used an electrostatic "motor".

In principle, there are two possibilities.

1. The stators plate sound goes along them, as well as at traditional Hale.

2. The stators rods,sound goes through them, in the space between the rods.

Expected strongly increased sensitivity.

Conductor width and depth of the "folds" principle is not limited to the distance between the magnets, like the AMT.

The stator is located at an optimum distance from the film and can be very thin.

Thanks !

Attachments

Last edited:

Hi,

I dn't know of anyone ever building a electrostatic AMT, neither DIY nor commercial.

There has been a discussion about such a design a few years earlier.

IIrc the resume was, that it probabely won't function as expected.

Besides the obvious building difficulties, the biggest issue will be to achieve sufficient 'effective' capacitance.

To prevent phase issues towards higher frequencies the folds need to be small in depth.

This increases the percentage of unuseable fixed membrane area which -even not coated- will add considerable amounts of dead capacitance.

The small depth dimension will also restrict the membrane excursion to tiny levels.

This will increase the lower bandwidth limit.

As the electrostatic driving forces are considerably smaller then electrodynamic ones, it could well be, that You couldn't achieve the expected upper bandwidth limit due to the higher dynamic mass loading.

Within the working frequency range a simple planar membrane is already perfectly matching the air acoustic impedance (pure ohmic).

There are probabely more drawbacks hidden in that system, so that a practical implementation seems obsolete.

jauu

Calvin

I dn't know of anyone ever building a electrostatic AMT, neither DIY nor commercial.

There has been a discussion about such a design a few years earlier.

IIrc the resume was, that it probabely won't function as expected.

Besides the obvious building difficulties, the biggest issue will be to achieve sufficient 'effective' capacitance.

To prevent phase issues towards higher frequencies the folds need to be small in depth.

This increases the percentage of unuseable fixed membrane area which -even not coated- will add considerable amounts of dead capacitance.

The small depth dimension will also restrict the membrane excursion to tiny levels.

This will increase the lower bandwidth limit.

As the electrostatic driving forces are considerably smaller then electrodynamic ones, it could well be, that You couldn't achieve the expected upper bandwidth limit due to the higher dynamic mass loading.

Within the working frequency range a simple planar membrane is already perfectly matching the air acoustic impedance (pure ohmic).

There are probabely more drawbacks hidden in that system, so that a practical implementation seems obsolete.

jauu

Calvin

Hi Svjatoslav, Thanks for your interest in the subject. I started this thread http://www.diyaudio.com/forums/planars-exotics/153220-electrostatic-amt.html

Sorry if it is a bit rambling, and that my early diagrams could have been better presented. I think Calvin raises several valid points that would occur to an experienced ESL person, which I am not.

The unfortunate conclusion is that an ES AMT is not really viable and that I should really wind up the thread with an obituary for the idea!

Perhaps the main issue is the lack of strength of an ES "motor", something compounded by the need to generate a pressure element as well as velocity due to the improved impedance match to the air the AMT provides.

Keith

Sorry if it is a bit rambling, and that my early diagrams could have been better presented. I think Calvin raises several valid points that would occur to an experienced ESL person, which I am not.

The unfortunate conclusion is that an ES AMT is not really viable and that I should really wind up the thread with an obituary for the idea!

Perhaps the main issue is the lack of strength of an ES "motor", something compounded by the need to generate a pressure element as well as velocity due to the improved impedance match to the air the AMT provides.

Keith

Hi,

I dn't know of anyone ever building a electrostatic AMT, neither DIY nor commercial.

There has been a discussion about such a design a few years earlier.

IIrc the resume was, that it probabely won't function as expected...

jauu

Calvin

Thanks!

Last edited:

Probably the idea at an early stage of its development.

The usual stage of the process before the practical realization of most ideas.

..........................

In this regard, it was hot debate about the impossibility of implementing the full-range speaker impedance electrodynamic 1000-2000 ohms. And ended up successfully.

The usual stage of the process before the practical realization of most ideas.

..........................

In this regard, it was hot debate about the impossibility of implementing the full-range speaker impedance electrodynamic 1000-2000 ohms. And ended up successfully.

- Status

- Not open for further replies.