Member

Joined 2006

Well, for the AVX wet Tantalum series....

Look how much they cost!

AVX Tantalum Capacitors - Wet | Mouser

Look how much they cost!

AVX Tantalum Capacitors - Wet | Mouser

And, yes - manufacturers describe tant caps as "most reliable, etc, etc", and simultaneously put "1000 hours" parameters life in datasheet - so I don't know what to think. It causes some portion of cognitive dissonance.

All manufacturers are equal but some are more equal than others 🙂

In the electrolytic cap world there is Lelon and Rubycon. From what brand would you buy caps?

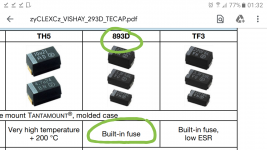

Btw one can wonder about a built in fuse but aluminium caps have a safety vent....

In the electrolytic cap world there is Lelon and Rubycon. From what brand would you buy caps?

Btw one can wonder about a built in fuse but aluminium caps have a safety vent....

Last edited:

Hello,

Let's take a CTS20 22µF/40V in the high pass filter for a boomer, which cut is at 400Hz:

- https://www.sonectrad.com/firadec/2243-condensateur-tantale-a-electrolyte-solide-cts-20-cts-20e.html

- Tantalum Capacitors. Condensateurs au Tantale - PDF

Look page 40, value for Tg δ = 6.

So, we can deduct that ESR = 108 Ohm.

C'est bête, but it will never cut at 400 Hz.

Another information concerning the distorsion, this AN is really depressing:

- Do Passive Components Degrade Audio Quality in Your - Maxim

Specially fig 8.

Let's take a CTS20 22µF/40V in the high pass filter for a boomer, which cut is at 400Hz:

- https://www.sonectrad.com/firadec/2243-condensateur-tantale-a-electrolyte-solide-cts-20-cts-20e.html

- Tantalum Capacitors. Condensateurs au Tantale - PDF

Look page 40, value for Tg δ = 6.

So, we can deduct that ESR = 108 Ohm.

C'est bête, but it will never cut at 400 Hz.

Another information concerning the distorsion, this AN is really depressing:

- Do Passive Components Degrade Audio Quality in Your - Maxim

Specially fig 8.

Last edited:

Your links don't work. I understand you want to use a tantalum cap for a filter. I don't think polarized tantalum caps are a good choice for that specific purpose, nor would polarized aluminium electrolytic caps be good candidates.

Then there is a wrong choice what type tantalum is chosen.

Then there is a wrong choice what type tantalum is chosen.

Last edited:

I know what I think. 1000 hours service life is about 6 months @ 14 hours a day. I only use $1 to $2 tantalums in switcher supplies where the high frequency capability is probably key. The $177 wet tantalums I don't use at all.And, yes - manufacturers describe tant caps as "most reliable, etc, etc", and simultaneously put "1000 hours" parameters life in datasheet - so I don't know what to think. It causes some portion of cognitive dissonance.

And I just replaced a 50 hour 6 year old $300 switcher supply (14 v 35 amps) that failed with a 40 lb EI transformer supply (14 v 50 amps) that failed due to 26 year old electrolytic caps. The 100000 uf cap leaked enough current to pull output down below regulator cutoff but hadn't exploded yet. No tantalums in that boat anchor.

Last edited:

In 2008 when I was working at Rockwell-Collins, now Collins Aerospace(now part of UTC) they issued a directive about tantalum capacitors that said that no new designs shall use tantalum capacitors without a 10 ohm or greater resistor in series with them. Pilots hate the smell of tantalum smoke in the cockpit!

In 2008 when I was working at Rockwell-Collins, now Collins Aerospace(now part of UTC) they issued a directive about tantalum capacitors that said that no new designs shall use tantalum capacitors without a 10 ohm or greater resistor in series with them. Pilots hate the smell of tantalum smoke in the cockpit!

I hear some of the avionics cooling fans are changing to ceramic ball bearings for similar reasons. Smoke in the cockpit from fans siezing is too commonplace.

When I worked in design at HP, in the mid 90's, we were only allowed to us fused tantalums, just in case one went in backwards or failed short, kemet still makes them, but I would use a Nichicon UKL instead for audio if you need low leakage.

https://content.kemet.com/datasheets/KEM_T2010_T496.pdf

When the tantalum prices went through the roof in the 2000's we were directed to use MLCC instead.

https://content.kemet.com/datasheets/KEM_T2010_T496.pdf

When the tantalum prices went through the roof in the 2000's we were directed to use MLCC instead.

Last edited:

Did you ever run into linearity problem when using MLCC caps? Was probably in the 90's, the company I worked at needed and had designed outside a very sharp 187.5 KHz filter. As can be imagined, the filter used ferrites and some largish ceramic capacitors. In testing, we found the filters had a terrible IP3 point, which we traced to non-linearities in both the ferrites and the ceramic capacitors.

[In the inductors, permeability and hence the inductance changed dynamically with signal current, and with the caps the dielectric constant and hence the capacitance changed dynamically with applied signal voltage.]

[In the inductors, permeability and hence the inductance changed dynamically with signal current, and with the caps the dielectric constant and hence the capacitance changed dynamically with applied signal voltage.]

Last edited:

I was doing mostly digital design, but I do know that there are drastic differences between the different dielectric chemistry's, I usually always use NPO/COG, unless it is for a bypass application where you usually can get away with X7R. Never use Z types.

It was a short stint, they bought our lab from Alcatel, we put out two products then they sold us off to McDATA in Broomfield,Co.Which division were you working at ??

Lab was labeled CNO, Canadian Networks Op, part of CSO, Computer Systems Org.

The lab designed Fibre Channel Switches used for data centers connecting servers and storage.

When I worked in design at HP, in the mid 90's, we were only allowed to us fused tantalums, just in case one went in backwards or failed short, kemet still makes them, but I would use a Nichicon UKL instead for audio if you need low leakage.

Coincidentally, I had to replace two Kemet solid Ta caps while testing out new plugins for an HP 54720D oscilloscope this week - an early 90s design. Boy they smell bad when they light up! 🙂

These were 22µF 20V units, and I replaced them with 22µF 25V to get a little extra voltage derating. I formed them to 20V and made sure the leakage decayed to less than 20nA - this seemed to weed out a few caps that wanted to leak more, a sign that the dielectric film is not stable. Forming a solid Ta will allow new dielectric to be created while removing shorts and weak oxide. The Mn02 can be consumed slowly to grow more oxide, but if it gets consumed too quickly, you have a fuel-oxidizer system that lights up - no fun!!

The originals failed since they were in power supply circuits with no current limit - unlimited current surges are what makes solid Ta caps go poof. In signal applications where current cannot change rapidly, a solid Ta can last truly forever with extremely low leakage, something a wet Al cap cannot do. I would have preferred to use something other than solid Ta, but in this scope, space constraints make that tough, so I chose a higher voltage rating instead.

Good info Monte, I do recall seeing a board severely damaged with a failed tant, burnt a hole right through it. Seen them glow orange too, when put in backwards. Kemet is the only mfg that I know of that makes fused tants and only in smt packages.

A Amber 3501 audio test set, that I have, uses a ton of those blue tants, every once and a while one shorts the supply out. At least when they fry it is obvious which one it is 🙂

A Amber 3501 audio test set, that I have, uses a ton of those blue tants, every once and a while one shorts the supply out. At least when they fry it is obvious which one it is 🙂

- Home

- Design & Build

- Parts

- Electrolytic vs Tantalum cap for audio use