Have an EAR "the preamp" from Tim de Paravicini.

Is from the eighties.

Tube complement is 6*ECC83, 4*PCC88, 4*PCF80.

Can anyone help with schematics or other info. Like to rebuild it.

Regards, Reinhard

Is from the eighties.

Tube complement is 6*ECC83, 4*PCC88, 4*PCF80.

Can anyone help with schematics or other info. Like to rebuild it.

Regards, Reinhard

post some pics , so we can see what can be critical ,needing change

generally electrolyt caps and nothing else , if built properly

tubes needing check on tester ( or in situ , knowing parameters/schematic) , but it could happen that they didn't had big mileage .....

generally electrolyt caps and nothing else , if built properly

tubes needing check on tester ( or in situ , knowing parameters/schematic) , but it could happen that they didn't had big mileage .....

A photo will make it much easier to identify the model (there are a couple plus DIY versions out there).

Looks pretty clean.

Is this a working specimen, faulty or unknown?

As ZM says, generally change out the electrolytics. Test the valves or get some fresh, matched NOS if you feel like it. Perhaps change out the potentiometers if scratchy, and clean the contacts in the valve bases should be a good start.

There doesn't seem to be any readily available sources of a schematic for this one. The nearest is the 802 but although it looks similar externally, 'the preamp' predated the 802 Mk1 and is quite different. Working without a schematic might be the only option.

What are your goals for rebuilding it?

Is this a working specimen, faulty or unknown?

As ZM says, generally change out the electrolytics. Test the valves or get some fresh, matched NOS if you feel like it. Perhaps change out the potentiometers if scratchy, and clean the contacts in the valve bases should be a good start.

There doesn't seem to be any readily available sources of a schematic for this one. The nearest is the 802 but although it looks similar externally, 'the preamp' predated the 802 Mk1 and is quite different. Working without a schematic might be the only option.

What are your goals for rebuilding it?

It is working with cracks and plops and hum. More on Phono than line.

Will try my very best,

Thank you, Reinhard

Will try my very best,

Thank you, Reinhard

Member

Joined 2009

Paid Member

I'm NO expert.

But I'd not be swapping out any of the parts - this is an original and I'd want to keep it that way, caps and all, unless it was clear that parts had become defective.

I would focus on a good clean. Cleaning dust and grime off switch contacts, volume controls, plugs and sockets and the tube sockets. Be careful any solvents used aren't aggressive enough to damage anything like writing etc.

Perhaps in high voltage sections it is worth cleaning the pcb surfaces to reduce possible leakage currents.

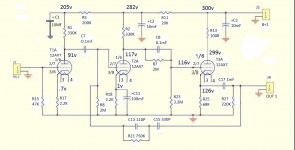

Then I would reverse engineer the schematic from the pcb and wiring before doing much more than that. Post the schematic so it can be reason-checked and curious folk can ogle it.

Do you have an oscilloscope ? multi-meter ? - can be helpful in learning what is going on inside.

But I'd not be swapping out any of the parts - this is an original and I'd want to keep it that way, caps and all, unless it was clear that parts had become defective.

I would focus on a good clean. Cleaning dust and grime off switch contacts, volume controls, plugs and sockets and the tube sockets. Be careful any solvents used aren't aggressive enough to damage anything like writing etc.

Perhaps in high voltage sections it is worth cleaning the pcb surfaces to reduce possible leakage currents.

Then I would reverse engineer the schematic from the pcb and wiring before doing much more than that. Post the schematic so it can be reason-checked and curious folk can ogle it.

Do you have an oscilloscope ? multi-meter ? - can be helpful in learning what is going on inside.

Tube socket and pot / switch cleaning, followed by some new/used and tested tubes would work wonders.

Those blue axial electrolytics look to be made by Ero and may still be available; I used ERO caps that looked exactly the same bodystyle and color for a McIntosh 250 (SS amp) rebuild. I would also replace the radial caps.

edit: or Roederstein caps. Been a few years.

Those blue axial electrolytics look to be made by Ero and may still be available; I used ERO caps that looked exactly the same bodystyle and color for a McIntosh 250 (SS amp) rebuild. I would also replace the radial caps.

edit: or Roederstein caps. Been a few years.

Last edited:

from here, it's an EAR 802, if it helps.

The OP's one is the predecessor to the 802. It has 14 tubes versus the 6 in the 802.

Tube socket and pot / switch cleaning, followed by some new/used and tested tubes would work wonders.

Those blue axial electrolytics look to be made by Ero and may still be available; I used ERO caps that looked exactly the same bodystyle and color for a McIntosh 250 (SS amp) rebuild. I would also replace the radial caps.

edit: or Roederstein caps. Been a few years.

+1

Hum can be caused by the breakdown of the power supply electrolytic caps - I'd replace those as a minimum.

+1

I will not neglect the increase of the mains voltage either.

I had the case with a CJ recently to have the ECC83 had cathode / heater leaks.

I sold some as a professional seller several years ago, but I never opened one, it was still "magic boxes" for me at the time.

I will not neglect the increase of the mains voltage either.

I had the case with a CJ recently to have the ECC83 had cathode / heater leaks.

thanks for the info .The OP's one is the predecessor to the 802. It has 14 tubes versus the 6 in the 802.

I sold some as a professional seller several years ago, but I never opened one, it was still "magic boxes" for me at the time.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Tubes / Valves

- EAR the preamp