Thanks to all for help 🙂.

The next task is to pull terminal plate out of speaker and do not break it down 🙂.

The next task is to pull terminal plate out of speaker and do not break it down 🙂.

Hey Guys,

Do you know what is real crossover point in DM 3/7? Spec claims 1800Hz, but this looks very low when there is 2600Hz for 2/7. Anyone has any experience or measurements?

Thanks

Do you know what is real crossover point in DM 3/7? Spec claims 1800Hz, but this looks very low when there is 2600Hz for 2/7. Anyone has any experience or measurements?

Thanks

Terminals is glued tightly. I pulled one out with some effort but the second one is fixed dead. What the hell Dynaudio? What is the sense in gluing terminals?

Don't know what to do. May be hairdryer will help?

If you have a multimeter, put it on the ohms scale and us it to trace continuity in the foil under the resistors....

Judging by the looks of the LP inductor from the opening post, its inductance is approx. in the 1-1,5 mH range, with a 6.8 uF for two units in parallel (4 ohm), one could easily believe that xo point being as mentioned in specs, is indeed correct.

Just to resurrect this old thread, R4 (33 ohms) goes from tweeter (+) to ground and is the second half of the L-pad attenuator ahead of the tweeter. L1 is 1.0mH and 0.44 ohms, whilst C2 (6.8uF) is an electrolytic with ~0.4 ohms series resistance and Vloss of ~1%. L3 is 0.275mH and 1.0 ohms.

There are a few obvious upgrades without changing the crossover design. Most important is to replace L1, which is the low pass inductor in series with the two bass drivers, for one with a lower series resistance. I suggest a target resistance that is 1/20 or less of the nominal bass driver impedance of 4 ohms, namely <0.2 ohms. A suitable inductor with low loss that can still be made to fit on the circuit board is the Jantzen P-core 1mH part number 000-5212, which has series resistance of 0.125 ohms. One side of the core end discs will need to be ground flat to make the inductor sit close enough to the circuit board to allow the assembly to fit through the input panel hole.

An air core inductor would be better, but then needs to be mounted off the circuit board, and care needs to be taken to avoid adding series resistance in the inductor loom and/or creating a loosely coupled air core transformers with the woofer and/or tweeter leads.

Secondly C2 should be replaced with a film capacitor like the Jantzen CrossCap part number 001-0258. The ESR of 0.4 ohms lost by removal of the bipolar capacitor should be added to the series resistor R5, which should therefore be changed from 2.2 to 2.7 ohms to keep the same time constant in this leg.

C1 (12 uF film) is perfectly adequate and replacement will not bring significant gains. Likewise changing L3 won't do much, and in any case R2 would need to be adjusted to compensate for any change in the series resistance of L3 if it is changed.

The output from the woofers will increase by almost 1dB thanks to the lower series resistance of the inductor. Tweeter attenuator R3 and/or R4 will need to be adjusted to restore the bass/treble balance of the system.

There is a simple modification for the tweeter. The plastic rear chamber is resonant, with ripples visible in the impulse response. The dimple in the chamber can be filled with a mastic type damping material, and then a circle of mastic type damping cut to the size of the chamber pressed onto the rear an into the fins. That will sweeting up the high mids and highs.

The lower third of the cabinet has no bituminous damping and can be improved by adding it on either side panel.

I have just ordered some components to upgrade a pair of DM3/7s I have in the workshop for a client. I will post the final values for R3 and R4 in a few days when I balance the system after the other mods.

There are a few obvious upgrades without changing the crossover design. Most important is to replace L1, which is the low pass inductor in series with the two bass drivers, for one with a lower series resistance. I suggest a target resistance that is 1/20 or less of the nominal bass driver impedance of 4 ohms, namely <0.2 ohms. A suitable inductor with low loss that can still be made to fit on the circuit board is the Jantzen P-core 1mH part number 000-5212, which has series resistance of 0.125 ohms. One side of the core end discs will need to be ground flat to make the inductor sit close enough to the circuit board to allow the assembly to fit through the input panel hole.

An air core inductor would be better, but then needs to be mounted off the circuit board, and care needs to be taken to avoid adding series resistance in the inductor loom and/or creating a loosely coupled air core transformers with the woofer and/or tweeter leads.

Secondly C2 should be replaced with a film capacitor like the Jantzen CrossCap part number 001-0258. The ESR of 0.4 ohms lost by removal of the bipolar capacitor should be added to the series resistor R5, which should therefore be changed from 2.2 to 2.7 ohms to keep the same time constant in this leg.

C1 (12 uF film) is perfectly adequate and replacement will not bring significant gains. Likewise changing L3 won't do much, and in any case R2 would need to be adjusted to compensate for any change in the series resistance of L3 if it is changed.

The output from the woofers will increase by almost 1dB thanks to the lower series resistance of the inductor. Tweeter attenuator R3 and/or R4 will need to be adjusted to restore the bass/treble balance of the system.

There is a simple modification for the tweeter. The plastic rear chamber is resonant, with ripples visible in the impulse response. The dimple in the chamber can be filled with a mastic type damping material, and then a circle of mastic type damping cut to the size of the chamber pressed onto the rear an into the fins. That will sweeting up the high mids and highs.

The lower third of the cabinet has no bituminous damping and can be improved by adding it on either side panel.

I have just ordered some components to upgrade a pair of DM3/7s I have in the workshop for a client. I will post the final values for R3 and R4 in a few days when I balance the system after the other mods.

Following from my previous post, R3 needs to be changed to 2.2 ohms to bring the tweeter level up to match the woofers, R4 can stay the same at 33 ohms. I also thought it was worthwhile to add some damping to the lower front panel below the woofers.

The tweaked crossovers add a bit of air to the top end, remove quite a bit of nasal-ness in the mids, reduce bass compression and mushiness, and add depth to the bass - overall very worthwhile improvements IMHO. Just how much benefit in any particular setup will depend on how good the amplification and speaker leads are.

The tweaked crossovers add a bit of air to the top end, remove quite a bit of nasal-ness in the mids, reduce bass compression and mushiness, and add depth to the bass - overall very worthwhile improvements IMHO. Just how much benefit in any particular setup will depend on how good the amplification and speaker leads are.

I did the same modifications to my Dynaudio DM 2/6s, I changed the caps and series-inductor and damped the tweeter's chamber from the outside with heated 4mm bitumen. But the sound didn't improve that much.

I then looked at Stereophile's measurements of the Excite X12 (identic, newer version of the 2/6) and discovered that:

1. The ¾" MDF walls were too soft to handle the sub-100Hz power, they flexed and stored lots of bass enegy, causing woody/boxy colorations in the bass and lower midrange.

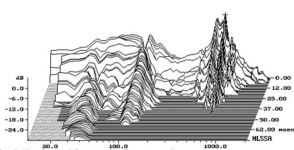

2. There was standing-wave problems in the cabinet, with lots of midrange energy storage between 500-1000Hz, also visable on the measurements of the port-output, blurring the important intelligibility range around 1kHz, making vocal sound a little nasal.

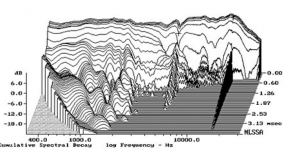

3. And the midwoofer had the typical Dynaudio 15W undamped 5kHz membrane breakup-peak (you can see this peak in spec sheets of Dynaudio 15W drivers, and in Stereophile's measurements of speakers with 6" Dynaudios), and a peak like this can cause wide-range distortion problems in the upper midrange / lower treble; like sharpness, sibilance, listener fatigue, etc.

To fix #1 I first glued 2mm aluminum sheets to the walls inside the cabinet, and then 4-8mm bitumen. This stiffened up and damped the walls. I attached heated bitumen on the baffle, lots of it, actually, shaping it into place when it was hot. The flimsy port was also treated with bitumen.

To fix #2 I threw away the 2" foam pads (don't like this material) and replaced it with slightly compressed 2" fibre glass on all walls, and then filled the rest of the cabinet with fluffy fibre glass. You are not suppose to have fluffy glass fibers in ported designs – health care – so the fiber glass was put inside silk stockings.

To fix #3 I put a sharp (not broad) 5kHz parallell notch in the filter.

These mods did it. Now the DM 2/6s sound relaxed and quiet and clean and clear, better controlled in the low end, more real soundig, no bass-bloat, no woody/boxy colorations, everything was improved, from the bass to the treble.

These low-priced Dynaudios are really diamonds in disguise, great High-End drivers, great potensial.

I then looked at Stereophile's measurements of the Excite X12 (identic, newer version of the 2/6) and discovered that:

1. The ¾" MDF walls were too soft to handle the sub-100Hz power, they flexed and stored lots of bass enegy, causing woody/boxy colorations in the bass and lower midrange.

2. There was standing-wave problems in the cabinet, with lots of midrange energy storage between 500-1000Hz, also visable on the measurements of the port-output, blurring the important intelligibility range around 1kHz, making vocal sound a little nasal.

3. And the midwoofer had the typical Dynaudio 15W undamped 5kHz membrane breakup-peak (you can see this peak in spec sheets of Dynaudio 15W drivers, and in Stereophile's measurements of speakers with 6" Dynaudios), and a peak like this can cause wide-range distortion problems in the upper midrange / lower treble; like sharpness, sibilance, listener fatigue, etc.

To fix #1 I first glued 2mm aluminum sheets to the walls inside the cabinet, and then 4-8mm bitumen. This stiffened up and damped the walls. I attached heated bitumen on the baffle, lots of it, actually, shaping it into place when it was hot. The flimsy port was also treated with bitumen.

To fix #2 I threw away the 2" foam pads (don't like this material) and replaced it with slightly compressed 2" fibre glass on all walls, and then filled the rest of the cabinet with fluffy fibre glass. You are not suppose to have fluffy glass fibers in ported designs – health care – so the fiber glass was put inside silk stockings.

To fix #3 I put a sharp (not broad) 5kHz parallell notch in the filter.

These mods did it. Now the DM 2/6s sound relaxed and quiet and clean and clear, better controlled in the low end, more real soundig, no bass-bloat, no woody/boxy colorations, everything was improved, from the bass to the treble.

These low-priced Dynaudios are really diamonds in disguise, great High-End drivers, great potensial.

Attachments

Absolutely fantastic Animal! You've done a lot more than I bothered with, and I see for good reason. (BTW I also wrap the ports with constrained damping material. It's a bit of a cheap cost saving by Dynaudio on something worth so little.) I agree entirely that the DM3/7s really are based on very good components and have great potential.

I have F220s which have similar issues to the DM3/7s, although they are a step better all round. The main difference, however, is the implementation of a 1st order crossover in the F220s, rather than the 2nd order of the DM3/7s. First order crossovers give quite superior power response in a room and are much less fussy about room placement. Having the two systems side by side with my poor man's ABX comparator really revealed the benefit of a properly implement 1st order crossover over higher order crossovers. The difference was extraordinary IMHO.

I'm sure the DM3/7 drives are good enough to be upgraded with (upgraded) F220 crossovers which, with your mods, would put their performance into the $10k plus region.

I have F220s which have similar issues to the DM3/7s, although they are a step better all round. The main difference, however, is the implementation of a 1st order crossover in the F220s, rather than the 2nd order of the DM3/7s. First order crossovers give quite superior power response in a room and are much less fussy about room placement. Having the two systems side by side with my poor man's ABX comparator really revealed the benefit of a properly implement 1st order crossover over higher order crossovers. The difference was extraordinary IMHO.

I'm sure the DM3/7 drives are good enough to be upgraded with (upgraded) F220 crossovers which, with your mods, would put their performance into the $10k plus region.

Last edited:

Animal, thanks for the reminder on the Dynaudio dust-cap ring at 5kHz. It explains why years ago John Dunlavy at Duntech (nothing to do with the current Duntech brand) used felt strips on Dynaudio 75mm dust-caps - to fix the time-domain response. I overlooked the 5kHz resonance in the woofer impedance thinking it not a serious aberration, but obviously it is. Looking at the spectral decay, a notch that narrow would be difficult to implement. I might play with damping a la Duntech. I did a bit of test and development at John Dunlavy's Technology Park facilities in the '80s and 90s.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Dynaudio DM 3/7 crossover scheme