I'm only answering this part since it doesn't look like anybody has. The resistor in series with the capacitor connected directly the the drivers is a Zobel used to compensate for the rising impedance of the drivers. Best practice recommends placing them as close as possible to the driver. So, yes, there is an advantage. However there may be no audible difference between placing the components on the crossover board or soldering directly across the driver terminals.Is there an any advantage to separating and placing only this part of the crossover close to the driver?

I do agree with the other posters, this looks to be a high quality crossover that doesn't need to be modified.

@sesebe I haven't forgotten you, I'll have the values soon.

@mtidge Thanks for the information, I'm taking note of it for my prototype.

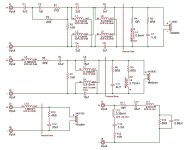

I agree, it's probably a good crossover design, as I said in an earlier post, my idea is not to invent a new one, but to copy it with better parts. I think the company had to deal with price and space problem to be able to put this crossover into the cabinet, which I won't. I think the resistors used can be of better quality. I'm looking for AOC resistors from Solen, or maybe Caddock, Path Audio but no Duelund, too expensive. The blue capacitor we see is made of polyester and not polypropylene, probably due to lack of space. Will be replace with a polypropylene. The coils are all air cores, I don't see a problem there, but I don't want to destroy the crossover, so I'm going to have new coils that meet the same specs (DCR) so as not to throw it off balance. Just by upgrading the parts, I end up with a crossover that's almost double the size.

I'm thinking about whether to replace the Solen condos witch is already good caps with Solen Film foil, Clarity cap CSA or CMR, Jantzen superior Z cap or if I put some bypass capacitors, like Solen Teflon or Miflex for the mid-tweeters section.

In the 80's I had made a copy of a crossover this way, and I had replaced the original with my copy, and since I had two pairs of the same speakers,

that way I could make a quick comparison between the two.

I had several people listen to the whole thing, and all of them were unanimous, my copy was much better than the original,

which was nevertheless seems very good before they heard mine.

@mtidge Thanks for the information, I'm taking note of it for my prototype.

I agree, it's probably a good crossover design, as I said in an earlier post, my idea is not to invent a new one, but to copy it with better parts. I think the company had to deal with price and space problem to be able to put this crossover into the cabinet, which I won't. I think the resistors used can be of better quality. I'm looking for AOC resistors from Solen, or maybe Caddock, Path Audio but no Duelund, too expensive. The blue capacitor we see is made of polyester and not polypropylene, probably due to lack of space. Will be replace with a polypropylene. The coils are all air cores, I don't see a problem there, but I don't want to destroy the crossover, so I'm going to have new coils that meet the same specs (DCR) so as not to throw it off balance. Just by upgrading the parts, I end up with a crossover that's almost double the size.

I'm thinking about whether to replace the Solen condos witch is already good caps with Solen Film foil, Clarity cap CSA or CMR, Jantzen superior Z cap or if I put some bypass capacitors, like Solen Teflon or Miflex for the mid-tweeters section.

In the 80's I had made a copy of a crossover this way, and I had replaced the original with my copy, and since I had two pairs of the same speakers,

that way I could make a quick comparison between the two.

I had several people listen to the whole thing, and all of them were unanimous, my copy was much better than the original,

which was nevertheless seems very good before they heard mine.

That's why my new plate will take up two times more space, so it's impossible to go back into the cabinet where it was original.

It's still a nice crossover compared to other companies like KEF, B&W etc., from the same era.

At least there are no electrolytic capacitors, nor an inductor with ferrite

It's still a nice crossover compared to other companies like KEF, B&W etc., from the same era.

At least there are no electrolytic capacitors, nor an inductor with ferrite

Well, it’s possible that R&D at Dynaudio counted in the effect of the stray fields of each of those coils, which lead to several issues like modulation and change of the theoretical inductance. But I’m afraid nobody did care about that, as they sold them anyway.

Hot glue by the way is excellent stuff to bond components to the board. Holds for ages, I can confirm that.

Hot glue by the way is excellent stuff to bond components to the board. Holds for ages, I can confirm that.

- Home

- Loudspeakers

- Multi-Way

- Dynaudio crossover questions