Today I was trying to get the REW beta impedance measurement to work. It didn't, but the frequency response measurement worked fine with an impedance rig, and I could even see cone resonances on the waterfall plot, so I decided to try an old idea I had.

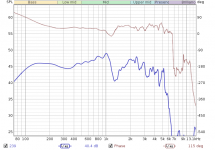

To be clear, I am using the frequency response measurement in REW to plot the voltage across a speaker as it is driven by an amplifier through a 39k resistor. This is not the acoustic response, but it does show damping of the dustcap resonance.

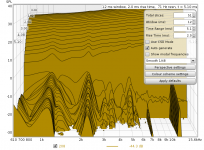

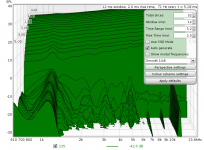

Yellow is stock and green is with the tape. The 9KHz resonance is due to something else changing between measurements, probably having to do with the rear motor vent.

This is an old Radioshack 40-1033 midwoofer, which would seem like an ideal test case due to it's squashed shape dustcap.

Before and after waterfall plots clearly show a resonance at 2.4KHz is suppressed by the tape. The tape has to be in the center and the shape of the hump as pictured is optimal. It is fairly sensitive to the shape. The hump is about 9mm wide and 7mm tall.

The tape is Scotch 35 red PVC electrical tape. It is thicker than generic electrical tape and you can tell when handling it why it might work well in this case. It is very damped and tapping the roll of tape has a very dead sound.

Simply putting a piece of tape on the dustcap has the opposite effect, the resonance moves down in frequency and gets worse. So I think the hump is acting like a mass damper.

To be clear, I am using the frequency response measurement in REW to plot the voltage across a speaker as it is driven by an amplifier through a 39k resistor. This is not the acoustic response, but it does show damping of the dustcap resonance.

Yellow is stock and green is with the tape. The 9KHz resonance is due to something else changing between measurements, probably having to do with the rear motor vent.

This is an old Radioshack 40-1033 midwoofer, which would seem like an ideal test case due to it's squashed shape dustcap.

Before and after waterfall plots clearly show a resonance at 2.4KHz is suppressed by the tape. The tape has to be in the center and the shape of the hump as pictured is optimal. It is fairly sensitive to the shape. The hump is about 9mm wide and 7mm tall.

The tape is Scotch 35 red PVC electrical tape. It is thicker than generic electrical tape and you can tell when handling it why it might work well in this case. It is very damped and tapping the roll of tape has a very dead sound.

Simply putting a piece of tape on the dustcap has the opposite effect, the resonance moves down in frequency and gets worse. So I think the hump is acting like a mass damper.

Attachments

Last edited:

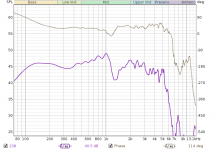

Off axis response with and without tape. Blue is without, purple is with

Oddly, the difference is not as apparent in the acoustic measurements as the impedance measurements.

I think this resonance is not storing energy but rejecting it at peaks in the impedance curve. Similar to how a notch filter does not continue to ring after it is stimulated. Or maybe I just have no idea.

Or perhaps the acoustic effect is more due to the tape acting like a phase plug. This would explain why the acoustic effect has repeating frequency components while the impedance effect does not.

Oddly, the difference is not as apparent in the acoustic measurements as the impedance measurements.

I think this resonance is not storing energy but rejecting it at peaks in the impedance curve. Similar to how a notch filter does not continue to ring after it is stimulated. Or maybe I just have no idea.

Or perhaps the acoustic effect is more due to the tape acting like a phase plug. This would explain why the acoustic effect has repeating frequency components while the impedance effect does not.

Attachments

Last edited:

I did a similar thing years ago. I had a woven carbon fiber 6 1/2 mid-bass in a 2-way. There was an obvious harshness at the top of it's band which I assumed was a break-up mode. I took the round, center piece from those self adhesive felt tweeter rings and cut it in half (semi-circle maybe 1 1/2 diameter?). I stuck it to the rather large (polypropylene) dust cap slightly above center. The imaging improved, the harshness was gone and there was a much better transition to the tweeter. I just had a Radio Shack SPL meter and test CDs; LONG before I ever had a PC. This obviously added some mass but I never detected that the transient response was affected and since the upper-mids improved; I left it there. That system is long since gone but it would have been nice to have a good microphone and test suite back in those days!

Neat trick, Kean. I like how it is reversible.

A dab of hot melt glue in a an asymmetric pattern could work too. Slightly pliable.

A dab of hot melt glue in a an asymmetric pattern could work too. Slightly pliable.

Last edited:

It's as though this tape comes with its own mass and damping. Nice contribution at 2k1 where I'd normally expect the larger breakup mode.

I did a similar thing years ago. I had a woven carbon fiber 6 1/2 mid-bass in a 2-way. There was an obvious harshness at the top of it's band which I assumed was a break-up mode. I took the round, center piece from those self adhesive felt tweeter rings and cut it in half (semi-circle maybe 1 1/2 diameter?). I stuck it to the rather large (polypropylene) dust cap slightly above center. The imaging improved, the harshness was gone and there was a much better transition to the tweeter. I just had a Radio Shack SPL meter and test CDs; LONG before I ever had a PC. This obviously added some mass but I never detected that the transient response was affected and since the upper-mids improved; I left it there. That system is long since gone but it would have been nice to have a good microphone and test suite back in those days!

I should add; do NOT try the self adhesive tweeter felt ring center trick above if you have a PAPER CONE! The adhesive is fairly strong; it would most likely tear the paper if removed. If you have a heavy plastic, metal or synthetic fiber dust cap; this is a cheap, quick and easy way to attempt "calming" and "smoothing" of break-up modes, etc. Of course, treating the dust cap doesn't always ensure improvement. Many times the cone itself is the culprit so dust cap mods. may have little to no effect...

- Home

- Loudspeakers

- Multi-Way

- Dust cap damping with caterpillar tape hump