Hello, I want to surface mount some drivers that are mounted in the inside of the box (ND90). I don't have a router so I can't flange the buffle (except maybe by using a file) this is why I thought of surface mounting. But The plywood is thick and it does leave any space in the inside for the driver to "breath" especially given the way this particular driver basket is shaped. Should I try and file a little bit of the inside to give more room around the basket. Should I try and flange the baffle by hand? Should I not worry about it?

First, let me say one thing: if you want to build speakers buy a router, especially if you plan to do it more than once. Even a cheap router will ease your work, and will help in making things that without one are impossible or really hard to perform.

Having said that, looking at the datasheet, the flange appears to be 1.5mm thick, so the ND90 is likely designed to be (also) surface mounted.

What you need to do is to scallop/chamfer the rear of the baffle to permit the driver to breathe. See here: chamfering driver holes Your case seems likely the case B in the above link, and needs to be transformed into C.

Ralf

Having said that, looking at the datasheet, the flange appears to be 1.5mm thick, so the ND90 is likely designed to be (also) surface mounted.

What you need to do is to scallop/chamfer the rear of the baffle to permit the driver to breathe. See here: chamfering driver holes Your case seems likely the case B in the above link, and needs to be transformed into C.

Ralf

This is how we did it before electricity, and yes can do an excellent job.Should I try and flange the baffle by hand?

Who here was alive before electricity? 😀

Says the guy who still uses a hand plane instead of sand paper...

Says the guy who still uses a hand plane instead of sand paper...

If you have a hand jigsaw you could use the angle setting on the foot to add a chamfer of sorts between the screw holes. Another option is to use 2 thinner pieces of ply for the baffle and make the rear piece with a larger cutout than the front piece to give some breathing space.

Cheers,

Rob.

Cheers,

Rob.

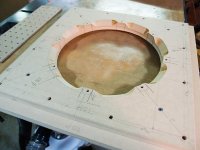

Thank you all for your help. I guess I will try doing it with the rasp. Would using a forster bit all around the hole diameter be a good idea? Moreover should how much should I do this? To the point I completely clear the wood around the "vents" of the driver's basket or that's not necessary?

If you have a forstner bit you can use it to hog out most of the material and clean it up with the rasp.

This is how we did it before electricity, and yes can do an excellent job.

Who did diy speakers before electricity??

Who here was alive before electricity?

haha, very funny! 🙂

They perform different jobs 🙂Who here was alive before electricity? 😀

Says the guy who still uses a hand plane instead of sand paper...

What about working in new developments before generators were popular. All normal work was by hand. Most finer work was by hand anyway.

I hope these look are OK.

Technically, hand done with a really coarse rasp is best since the more ragged/imperfect the job, the more diffuse its dispersion = less added damping required.

Technically, hand done with a really coarse rasp is best since the more ragged/imperfect the job, the more diffuse its dispersion = less added damping required.GM

Great now my boomily tuned boombox is going to have hifi quality.

Jokes aside how would a diffused backwave reduce the required stuffing?

Jokes aside how would a diffused backwave reduce the required stuffing?

- Home

- Loudspeakers

- Multi-Way

- Driver clearance