Hello everyone !

Long story short, I'm starting the design of my future main monitors for my mastering studio.

I currently have PMC which I have totally redone crossover-wise (with a Linea-Research ASC48F), with a 12" Volt, the famous ATC SM75-150S and an old Vifa D27 as the tweeter.

I plan do upgrade to 4x Purifi PTT10 per side as a 2x2 array to control horizontal and mostly vertical coverage a bit lower than usual (targeting floor bounce @ 205 Hz in my studio, 2.7 meters listening distance). To go with that on the mids and highs, I will either go :

1) Bliesma M74B / Bliesma T34B if I can get a properlly integrated system with a minimum of 500 Hz crossover on the mids and recoup the 8x Purifi woofers cost by selling the PMC.

2) ATC SM75-150S / Bliesma T34B if I need that lower 380 Hz crossover, can't sell the PMC and will probably sell a kidney instead 🙂

Both options will go anyway in a big dual waveguide. I started modeling and "Akabeking" but I'm facing a big problem : my current midrange waveguide is 620mm wide right now, and that takes a bit of horsepower to compute a model which is not crap below 4K (doing it with 2 symmetries and only computing a quarter of the waveguide). Problem is, for high frequencies, it gets really really too big and my desktop CPU wants to hara-kiri if I want a good HF prediction.

Adding to that, when I'm merging both waveguides to do a dual one, I have to get rid of the vertical symmetry, and it basically triples the number of triangles in the mesh, making it even more impossible to modelize. And I'm in the infinite baffle scenario, monitors will be flush mounted.

Here are my current best with artifacts on a really big mid waveguide (shallow but very large) and a smaller tweeter waveguide (not merged together, so this is the "target" response).

I still need to continue to optimize the "slopes" both waveguides give.

With 380 Hz crossover, so keeping the ATC mid :

With 500 Hz crossover, so Bliesma is okay now. It has a slight 600 Hz bump in DI, mostly caused by the vertical off-axis response.

Mid/HF crossover was put at 1.2 CtC with the lowest driver distance possible between midrange & tweeter, i.e. 112,5 mm.

To avoid loosing too much time and CPU by experimentation, I feel it's better to develop a smaller, KH420 sized waveguide, learn to optimize the merging of both, before going back to the monster I plan for my speakers 🙂

I tried two ways of merging :

1) Flat "speaker baffle" with single big waveguide around :

2) Generate both single waveguides, intersect them and radius the transition :

Both method keep the horizontal dispersion almost the same. Method 2 seems smoother in the vertical axis.

So before going further, and since it will not really be for me at the end (even though the examples above are 32x32 cm, which is exactly the size of the midrange & tweeter plate on my PMC so I could try it in my studio), I need your input : what would serve the community best ?

1) Considering the pedigree of the drivers, what would be the most useful woofer size goal to match ? single 10", single 12" ?

2) T34B or T25B ?

Are there people here already owning these drivers and access to a CNC router to compare measurements to simulations ? I will buy the drivers at some point, but not right now.

Long story short, I'm starting the design of my future main monitors for my mastering studio.

I currently have PMC which I have totally redone crossover-wise (with a Linea-Research ASC48F), with a 12" Volt, the famous ATC SM75-150S and an old Vifa D27 as the tweeter.

I plan do upgrade to 4x Purifi PTT10 per side as a 2x2 array to control horizontal and mostly vertical coverage a bit lower than usual (targeting floor bounce @ 205 Hz in my studio, 2.7 meters listening distance). To go with that on the mids and highs, I will either go :

1) Bliesma M74B / Bliesma T34B if I can get a properlly integrated system with a minimum of 500 Hz crossover on the mids and recoup the 8x Purifi woofers cost by selling the PMC.

2) ATC SM75-150S / Bliesma T34B if I need that lower 380 Hz crossover, can't sell the PMC and will probably sell a kidney instead 🙂

Both options will go anyway in a big dual waveguide. I started modeling and "Akabeking" but I'm facing a big problem : my current midrange waveguide is 620mm wide right now, and that takes a bit of horsepower to compute a model which is not crap below 4K (doing it with 2 symmetries and only computing a quarter of the waveguide). Problem is, for high frequencies, it gets really really too big and my desktop CPU wants to hara-kiri if I want a good HF prediction.

Adding to that, when I'm merging both waveguides to do a dual one, I have to get rid of the vertical symmetry, and it basically triples the number of triangles in the mesh, making it even more impossible to modelize. And I'm in the infinite baffle scenario, monitors will be flush mounted.

Here are my current best with artifacts on a really big mid waveguide (shallow but very large) and a smaller tweeter waveguide (not merged together, so this is the "target" response).

I still need to continue to optimize the "slopes" both waveguides give.

With 380 Hz crossover, so keeping the ATC mid :

With 500 Hz crossover, so Bliesma is okay now. It has a slight 600 Hz bump in DI, mostly caused by the vertical off-axis response.

Mid/HF crossover was put at 1.2 CtC with the lowest driver distance possible between midrange & tweeter, i.e. 112,5 mm.

To avoid loosing too much time and CPU by experimentation, I feel it's better to develop a smaller, KH420 sized waveguide, learn to optimize the merging of both, before going back to the monster I plan for my speakers 🙂

I tried two ways of merging :

1) Flat "speaker baffle" with single big waveguide around :

2) Generate both single waveguides, intersect them and radius the transition :

Both method keep the horizontal dispersion almost the same. Method 2 seems smoother in the vertical axis.

So before going further, and since it will not really be for me at the end (even though the examples above are 32x32 cm, which is exactly the size of the midrange & tweeter plate on my PMC so I could try it in my studio), I need your input : what would serve the community best ?

1) Considering the pedigree of the drivers, what would be the most useful woofer size goal to match ? single 10", single 12" ?

2) T34B or T25B ?

Are there people here already owning these drivers and access to a CNC router to compare measurements to simulations ? I will buy the drivers at some point, but not right now.

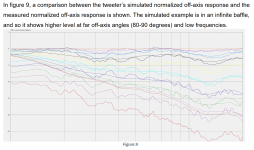

As long as the simulations are done properly it should show very accurate results for the T25B at least. I would assume the same is true of the T34B. When I did my speaker project (Bliesma T25B, Kartesian Mid120_vHE, Kartesian WOM300_vDIY) I compared my AKABAK simulations to the measured results and the agreement was extremely good. See image below:Are there people here already owning these drivers and access to a CNC router to compare measurements to simulations ? I will buy the drivers at some point, but not right now.

This is from 1kHz to 20kHz. The tweeter waveguide had to be simulated in an infinite baffle, which is what causes the large differences at low frequencies and far off-axis angles. I simply do not have enough memory available to model the entire cabinet in high enough resolution for non-IB simulation of the tweeter. In any case the simulation and measurement matches almost perfectly from 4-20kHz from 0-70 degrees. I have no doubt they'd match even better if the whole cabinet was modelled and simulated (which I did for the midrange waveguide, and that showed even better agreement).

I definitely think the T25B in a waveguide can keep up with a single 12''. T34B seems overkill for this application, to me. In my waveguide the T25B has more than 100dB/W on the lower end of its passband (between 1.5kHz and 4.5kHz) , which means you're never gonna be putting more than a watt into it for extended periods of time, even for listening positions far away. It can handle that just fine.2) T34B or T25B ?

Very cool project, good luck!

Hey Scgorg, it's actually your videos about Akabak that started me going 🙂

For my big HF waveguide, with 0.015m of edge length in Akabak, I already have

Solving size of 1k takes a few min, 5k ~2h IIRC and 10k the whole night.

From what i've read, you need 6 vertex per wavelength for good predictions.

That would need 0.003m edge length in Akabak, and with this number I don't think my computer can handle it.

At some point, I think the big one will be modeled more coarsely, you can learn to read through the artefacts, and maybe CNC in wood for test.

For the KH420-like one, I think it can be modeled and calculated without taking a week.

For my big HF waveguide, with 0.015m of edge length in Akabak, I already have

Solving size of 1k takes a few min, 5k ~2h IIRC and 10k the whole night.

From what i've read, you need 6 vertex per wavelength for good predictions.

That would need 0.003m edge length in Akabak, and with this number I don't think my computer can handle it.

At some point, I think the big one will be modeled more coarsely, you can learn to read through the artefacts, and maybe CNC in wood for test.

For the KH420-like one, I think it can be modeled and calculated without taking a week.

Speaking from experience, the kinds of problems we're often looking at here will be fine with just 4 elements per wavelength. Even 3 doesn't seem to change results much, as long as as small details are adequately modelled by the elements. COMSOL states the following about BEM simulation: "In general, the mesh should resolve the wavelength with 5 to 6 elements. The mesh should also resolve small details and curved surfaces adequately. For exterior problems, the mesh can in practice be slightly coarser and it typically suffices to use 4 elements per wavelength." I typically use Gmsh and do much finer mesh on the dome and surround, as well as the throat of the waveguide, compared to the rest of the assembly.From what i've read, you need 6 vertex per wavelength for good predictions.

That would need 0.003m edge length in Akabak, and with this number I don't think my computer can handle it.

For very high frequency simulations cutting out just the tweeter waveguide and simulating it alone is an option. It should give a reasonable idea of how it behaves above 10kHz, and allows much finer mesh.

Yes, I already use the curvature option in gmsh, but then increase the mesh resolution in Akabak depending if I want a quick or slow simulation. Maybe I should do it all in gmsh.

BTW, the numbers above are for the tweeter waveguide alone, and it's a quarter of the waveguide, with double symmetry setup in Akabak.

Picture this kind of tweeter waveguide, it's only slightly smaller than the mid one, and that's where it's complicated, even tweeter alone, to model in HF.

For a KH420 style one, it will be easier 🙂

BTW, the numbers above are for the tweeter waveguide alone, and it's a quarter of the waveguide, with double symmetry setup in Akabak.

Picture this kind of tweeter waveguide, it's only slightly smaller than the mid one, and that's where it's complicated, even tweeter alone, to model in HF.

For a KH420 style one, it will be easier 🙂

The inteface can easily chew your elements quickly if you make it fine enough to simulate to higher frequencies. You can also make a large flat baffle and simulate it as an exterior domain only. Then you can reduce the mesh size as you go further away from the drivers. If you make it IEC size there will only be effects below 300Hz or so. A speaker in a wall is not in a true infinite baffle anyway, unless the wall is really really big.

Don't let Akabak do the meshing if you are using CAD models. Tune the elements in gmsh based on how long you can wait for the sim to run.

You can get a long way in initial simulations by using quarter symmetry and truncating the vertical edge to be somewhat representative of what you have and separating out the tweter and mid. It will be somewhat idealized and not include every facet of the finished system but if you need to run more than a few iterations it will speed up development considerably.

Balancing element density, surface accuracy and solve time is not always easy but as said above when you go too low it becomes immediately obvious in the results and there is rarely much benefit to 6 elements per wavelength vs 3 or 4. Above 10K reliability of simulations drop considerably and using that as an upper limit for larger meshes can help too.

Solve time is also about the number of frequencies, making them a multiple of the processor cores stops wasted cycles and simulating separately in restricted frequency ranges can speed things up a lot.

Don't let Akabak do the meshing if you are using CAD models. Tune the elements in gmsh based on how long you can wait for the sim to run.

You can get a long way in initial simulations by using quarter symmetry and truncating the vertical edge to be somewhat representative of what you have and separating out the tweter and mid. It will be somewhat idealized and not include every facet of the finished system but if you need to run more than a few iterations it will speed up development considerably.

Balancing element density, surface accuracy and solve time is not always easy but as said above when you go too low it becomes immediately obvious in the results and there is rarely much benefit to 6 elements per wavelength vs 3 or 4. Above 10K reliability of simulations drop considerably and using that as an upper limit for larger meshes can help too.

Solve time is also about the number of frequencies, making them a multiple of the processor cores stops wasted cycles and simulating separately in restricted frequency ranges can speed things up a lot.

To add to what Fluid said, if you really want a high resolution simulation, you can restrict the amount of CPU threads AKABAK is allowed to use simultaneously, thereby lowering memory usage (due to how AKABAK does parallel processing). I've done this once, simulating a 12000 element waveguide + cabinet with only 5 out of my 32 threads as to not run out of RAM. That simulation took 5 days for 40 frequencies, IIRC. Not a reasonable method, but it does work if you just want to brute force something.

Thank you both for your tips !

Good to know that each thread does a frequency so I should in my case always go by multiples of 16.

And yes, maybe as a check, I can run 12 frequencies on 10-20k on a really fine mesh to correlate to more "full range" simulations with coarser meshes.

Fluid, in my case, where my "infinite baffle" finite wall ends up, big "non-environment room" absorption is there, except on the floor, so infinite baffle should still be the closest thing, right ?

I also have a question about waveguides in general :

Let's take the T25B normalized polars and identify the tweeter own directivity with points at 20k.

From what I understand, the curves I've drawn could be those of a waveguide on that tweeter, just needing the proper shape. Different shapes, size & depth would give different slopes, starting point of the slopes etc.

What I'm interested in because I read somewhere that at the extreme octave, the dispersion comes back to the radiator itself and the waveguide has no more effect. So, is an "un-obstructed" waveguide able to lift up these points at 20k (basically making the tweeter more omni there) ? Or does it absolutely need a phase plug, coherer like the Purifi tweeter, dispersion plate or something like that ?

Back on dual waveguide, it kind of forces a CtC distance. if I design the dual waveguide for M74B + T25B, I can go closer on the two drivers (94.5mm CtC). That would lead to a 1.2 CtC for ~4400 Hz. Is it too high ?

Maybe it's better to chose a good crossover frequency for both drivers, agree on a concept (like the 1.2 wavelength CtC) and then fix the according driver distances according to that.

For 34B, closest CtC is 112.5 mm, which gives already 3700 Hz, and is what I used in my first VituixCAD simulation for my next main monitors.

So, what would be the most useful crossover frequency to target for the community ?

Good to know that each thread does a frequency so I should in my case always go by multiples of 16.

And yes, maybe as a check, I can run 12 frequencies on 10-20k on a really fine mesh to correlate to more "full range" simulations with coarser meshes.

Fluid, in my case, where my "infinite baffle" finite wall ends up, big "non-environment room" absorption is there, except on the floor, so infinite baffle should still be the closest thing, right ?

I also have a question about waveguides in general :

Let's take the T25B normalized polars and identify the tweeter own directivity with points at 20k.

From what I understand, the curves I've drawn could be those of a waveguide on that tweeter, just needing the proper shape. Different shapes, size & depth would give different slopes, starting point of the slopes etc.

What I'm interested in because I read somewhere that at the extreme octave, the dispersion comes back to the radiator itself and the waveguide has no more effect. So, is an "un-obstructed" waveguide able to lift up these points at 20k (basically making the tweeter more omni there) ? Or does it absolutely need a phase plug, coherer like the Purifi tweeter, dispersion plate or something like that ?

Back on dual waveguide, it kind of forces a CtC distance. if I design the dual waveguide for M74B + T25B, I can go closer on the two drivers (94.5mm CtC). That would lead to a 1.2 CtC for ~4400 Hz. Is it too high ?

Maybe it's better to chose a good crossover frequency for both drivers, agree on a concept (like the 1.2 wavelength CtC) and then fix the according driver distances according to that.

For 34B, closest CtC is 112.5 mm, which gives already 3700 Hz, and is what I used in my first VituixCAD simulation for my next main monitors.

So, what would be the most useful crossover frequency to target for the community ?

Infinite baffle in BEM is using something of a cheat to make an assumption and make the simulation simpler.Fluid, in my case, where my "infinite baffle" finite wall ends up, big "non-environment room" absorption is there, except on the floor, so infinite baffle should still be the closest thing, right ?

It may be semantics but I would say it is not quite the same but it is closer to your reality than most. You can create a simple shape with low mesh density and assign it a wall damping value. You can use that to represent your NE absorption. Have a look at how many elements are used in your interface, that will give you a good idea how much the interface is contributing to your solve time.

There can be a point where the inherent directivity of the driver itself limits the dispersion. The shape of the dome and surround has a big effect on this. If you want the widest radiation then the Aluminium Bliesma drivers have that. The Be drivers do restrict the directivity at the highest frequencies.What I'm interested in because I read somewhere that at the extreme octave, the dispersion comes back to the radiator itself and the waveguide has no more effect. So, is an "un-obstructed" waveguide able to lift up these points at 20k (basically making the tweeter more omni there) ? Or does it absolutely need a phase plug, coherer like the Purifi tweeter, dispersion plate or something like that ?

There is a strong argument in a use case like yours for having the drivers be as close together as possible. In an environment where the room is so tightly controlled it is debateable whether the waveguides will offer much benefit and may force more compromise in positioning. It is possible without much trouble to cut part of the tweeters mounting flange down close to the motor on one or two sides. With a small waveguide for the tweeter you can match the directivity of the mid and tweeter quite well. I made a small waveguide 5mm deep for another member to match directivity between the M74B and T25B at 3K, it worked much better than the augerpro waveguide he had used before as that had too much directivity to match the M74B properly. There was an increase in edge diffraction as the waveguide was not so directive.That would lead to a 1.2 CtC for ~4400 Hz. Is it too high ?

When you have no reflections directivity is less of a factor on ultimate sound quality. The vertical off axis in your vituix sim above is pretty horrible and in a normal room that might be a real problem, but in your room I am not so sure.

Using a higher CTC distance like 1 wavelength or more is trying to balance the off axis sound and put the invevitable off axis dips to locations that are less harmful to the early reflections pattern. If you don't have any early reflections then a different compromise might be better overall.

It might be better to get the drivers and put them in a large flat baffle and test some of these things out in your own room. Is it better for you to have the mid go higher as the vertical dip isn't heard or is it better well integrated all around at 3K or lower like @IamJF does.

Yes for my mains, I plan anyway to put the driver the closest possible in to the dual waveguide, then it's easy to experiment in situ the different crossover frequencies. Being DSP active as well, delays are easy so I can make the drivers not exactly at the same depth by having the tweeter in a slightly less deep waveguide (6mm is enough), so their faceplates overlap and they are closer together. You can then have M74/34 being 100mm CtC and M74/25 84mm IIRC.

My question for CtC was for doing a classic KH420 waveguide, and publish the files for CNC / printing here so it could serve to other members, not in my studio with its high absorption. In that case, keeping in mind what kind of cross-over frequencies can be usefull and what concept of CtC would be useful, it may not be the best to keep them the closest possible.

But maybe it is too specific as the box itself influences the directivity and it perhaps can't really be made without having fixed width and depth of the speaker box, which at that point starts to become a full speaker specification instead of a "use it at your convenience" dual waveguide.

My question for CtC was for doing a classic KH420 waveguide, and publish the files for CNC / printing here so it could serve to other members, not in my studio with its high absorption. In that case, keeping in mind what kind of cross-over frequencies can be usefull and what concept of CtC would be useful, it may not be the best to keep them the closest possible.

But maybe it is too specific as the box itself influences the directivity and it perhaps can't really be made without having fixed width and depth of the speaker box, which at that point starts to become a full speaker specification instead of a "use it at your convenience" dual waveguide.

Anything with a CTC distance of 0.5 to 0.7 is generally the worst for vertically arranged drivers for use in an average cabinet in an average room. 1.2 wavelengths will more often than not produce the nicest looking CTA2034 measurements and the smoothest in room results when the distance cannot be under 0.3 WL or less at crossover.

Somewhere around 3K is possible with practical positioning if it is much higher then there will be more obvious vertical lobing issues that will show in the measurements.

Designing the right waveguide needs to take into account the cabinet or lack of it. A 2pi optimized waveguide is not usually the best that can be had in a 4pi cabinet.

Somewhere around 3K is possible with practical positioning if it is much higher then there will be more obvious vertical lobing issues that will show in the measurements.

Designing the right waveguide needs to take into account the cabinet or lack of it. A 2pi optimized waveguide is not usually the best that can be had in a 4pi cabinet.

Hello,

I'm planning to build a T25S + M74S + SB 34NRXL75-8 12" 3-way for home hifi purposes, with a listening distance of ~2.5. The possibility of designing a waveguide is new to me. Is this something I should be interested in, or you would want it in a professional environment only?

My father in law is a structural engineer with proper computaional horspepower in his possession, but the software costs waaay too much.

If you come up with something useful for this tweeter/mid combo, a model would be greatly appreciated.

I'm planning to build a T25S + M74S + SB 34NRXL75-8 12" 3-way for home hifi purposes, with a listening distance of ~2.5. The possibility of designing a waveguide is new to me. Is this something I should be interested in, or you would want it in a professional environment only?

My father in law is a structural engineer with proper computaional horspepower in his possession, but the software costs waaay too much.

If you come up with something useful for this tweeter/mid combo, a model would be greatly appreciated.

- Home

- Loudspeakers

- Multi-Way

- Double waveguide design for Bliesma mids and tweeters.