I use acad professionally, so, yes i also use it to design enclosures. Mainly as 2d plans.

I also started learning freecad to model parts for 3d printing and for use in kicad.

I also started learning freecad to model parts for 3d printing and for use in kicad.

Mechanical Engineering student here. I got my CAD program for free as a student and figured out its worth building them on CAD. Any design change costs you less time with sketches, plus you really get to see if your model is going to be easy to build or not.

I model all my enclosures and the PCB assembly and everything else except cables in FreeCAD. Else, nothing would fit together for sure.

However, I designed my first amp that I built like 25 years ago on paper. A few months ago, I found the old paper drawings and wonder how I managed to plan everything on paper, build it exacly according to plan and it fit together in the end. I guess using 3D CAD made me lose the ability to do CAD on paper.

However, I designed my first amp that I built like 25 years ago on paper. A few months ago, I found the old paper drawings and wonder how I managed to plan everything on paper, build it exacly according to plan and it fit together in the end. I guess using 3D CAD made me lose the ability to do CAD on paper.

One i have to learn, it is a bit opaque at first....learning freecad...

I am quite adept at 2D in VectorWorks.

dave

FreeCAD is the only serious 3D CAD I know that is free of charge. Getting into it takes some time. Tutorial videos are most helpful for learning.

What I would concentrate on for enclosures is the "part design" workbench.

Create a sketch, for example of the front panel contour, create a solid from this sketch, create another sketch for drills (each size need a separate sketch), drill the solid using the sketch(es), maybe another sketch for cutouts, subtract the cutouts from the solid, done, next part of the chassis.

I use FreeCAD for years now, but still know only a fraction. Fortunately enclosures are fairly easy to design.

Electronic assemblies are best imported into FreeCAD and put into the enclosure then. Either the ECAD outputs STEP or IDF. In any case, you would need 3D models of each and every component in your ECAD library, which is a challenge on its own. I don't know how to import IDF in FreeCAD 0.19 (but I'm sure there is a way) and still use a Python script in 0.16 for that. FreeCAD is changing constantly due to evolution. Workbenches come and go, workflows may change.

I find it was worth learning FreeCAD and can't imagine designing anything without.

You might also need a 2D CAD tool for data preparation (like LibreCAD) and Inkscape is also helpful preparing data for import into FreeCAD. For example you might have a PDF of an enclosure and want a 3D model of it. Instead of sketching the outlines, you might prefer importing them, especially since drawings are usually lacking many dimensions. So the workflow would be to import into Inkscape, convert to DXF, clean up the drawings in LibreCAD and import the DXF into FreeCAD to extrude solids. For complex geometries, this is likely faster than sketching on your own.

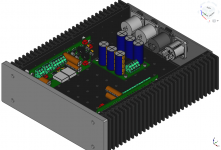

Attached example assembly is a study for a headphone amplifier. The chassis was drawn entirely in FreeCAD. I had no drawings of the chassis to start with, but the actual chassis my table to reverse engineer dimensions with a caliper. The PCB assemblies are imported via IDF interface. The chassis is a bit small for what I imagine to squeeze inside. I will likely move assemblies around for some time and then give up.

What I would concentrate on for enclosures is the "part design" workbench.

Create a sketch, for example of the front panel contour, create a solid from this sketch, create another sketch for drills (each size need a separate sketch), drill the solid using the sketch(es), maybe another sketch for cutouts, subtract the cutouts from the solid, done, next part of the chassis.

I use FreeCAD for years now, but still know only a fraction. Fortunately enclosures are fairly easy to design.

Electronic assemblies are best imported into FreeCAD and put into the enclosure then. Either the ECAD outputs STEP or IDF. In any case, you would need 3D models of each and every component in your ECAD library, which is a challenge on its own. I don't know how to import IDF in FreeCAD 0.19 (but I'm sure there is a way) and still use a Python script in 0.16 for that. FreeCAD is changing constantly due to evolution. Workbenches come and go, workflows may change.

I find it was worth learning FreeCAD and can't imagine designing anything without.

You might also need a 2D CAD tool for data preparation (like LibreCAD) and Inkscape is also helpful preparing data for import into FreeCAD. For example you might have a PDF of an enclosure and want a 3D model of it. Instead of sketching the outlines, you might prefer importing them, especially since drawings are usually lacking many dimensions. So the workflow would be to import into Inkscape, convert to DXF, clean up the drawings in LibreCAD and import the DXF into FreeCAD to extrude solids. For complex geometries, this is likely faster than sketching on your own.

Attached example assembly is a study for a headphone amplifier. The chassis was drawn entirely in FreeCAD. I had no drawings of the chassis to start with, but the actual chassis my table to reverse engineer dimensions with a caliper. The PCB assemblies are imported via IDF interface. The chassis is a bit small for what I imagine to squeeze inside. I will likely move assemblies around for some time and then give up.

Attachments

Member

Joined 2003

For DIY use OnShape and AutoCAD Fusion 360 are good "free" options. I don't get very detailed with CAD drawings for a speaker, mostly just to visualize proportions, driver locations and get the general dimensions down. Onshape is nice in that it is completely web based, no software required so can run on any computer with a web browser and internet connection.

Member

Joined 2003

When I read there is a free Auto CAD, I was excited. Turned out Auto CAD Fusion 360 is in deed free for hobbyists, non-commercial use, and for qualifying startups. The catch is just that it is cloud based and the terms and conditions may change any day.

This is what happened with DraftSight (Dassault), which used to be free as well and is not free anymore. I used DraftSight to clean up DXF files only, but sorely miss it now (this is why I'm still interested in CAD tools despite having tools I know and a pretty good workflow).

I can't figure out how to get Onshape for free. Maybe the students / educators license? Onshape is cloud based so, like with Auto CAD, you neither own the software, nor your designs and terms may change any day.

Both tools are not only simple CAD tools, but highly integrated development environments. Like Auto CAD Fusion 360 "unifies design, engineering, electronics, and manufacturing to connect your entire product development process into one cloud-based software". I could imagine that all the options may be overwhelming for hobbyists.

For me, cloud-run software and non-perpetual licenses are a failed investment. You are at the mercy of greedy corporations with no escape path.

This is what happened with DraftSight (Dassault), which used to be free as well and is not free anymore. I used DraftSight to clean up DXF files only, but sorely miss it now (this is why I'm still interested in CAD tools despite having tools I know and a pretty good workflow).

I can't figure out how to get Onshape for free. Maybe the students / educators license? Onshape is cloud based so, like with Auto CAD, you neither own the software, nor your designs and terms may change any day.

Both tools are not only simple CAD tools, but highly integrated development environments. Like Auto CAD Fusion 360 "unifies design, engineering, electronics, and manufacturing to connect your entire product development process into one cloud-based software". I could imagine that all the options may be overwhelming for hobbyists.

For me, cloud-run software and non-perpetual licenses are a failed investment. You are at the mercy of greedy corporations with no escape path.

by the way: I read that qcad is similar to (2d) Autocad. not tried it yet, though. it only supports DXF in the free version.free Auto CAD

QCAD and LibreCAD are very similar.

Here is the comaprison: QCAD vs. LibreCAD

LibreCAD is a fork of QCAD.

Initially, I had QCAD installed and suddenly my distribution renamed it to LibreCAD, but else it looked the same to me.

LibreCAD is a very basic, but good 2D only CAD.

Nothing is parametric, which makes it a bit cumbersome to change drawings in my opinion.

But for 2D design, it has some compelling features nonetheless.

Here is the comaprison: QCAD vs. LibreCAD

LibreCAD is a fork of QCAD.

Initially, I had QCAD installed and suddenly my distribution renamed it to LibreCAD, but else it looked the same to me.

LibreCAD is a very basic, but good 2D only CAD.

Nothing is parametric, which makes it a bit cumbersome to change drawings in my opinion.

But for 2D design, it has some compelling features nonetheless.

If you want really fast CAD work that doesn't require a lot of parts, then look to Shapr3D.

Shapr3D is the fastest if you don't need complex curves (uMake, only available for the ipad is the fastest with complex curves).

If you do need to integrate parts (particularly "off-the-shelf" parts) then you can always transfer over to Fusion 360 for further work on the model.

Unfortunately to achieve that sort of speed requires the use of a pen + tablet w/ *multi-touch, and is only available on ipad, MacOS, and now Windows.

Finally, it's a subscription services for $20 a month - but if you only need a month for your project then it's not exactly expensive.

*for Windows this means a Surface Tablet (or other Windows tablet) or one of the Wacom tablets that has multi-touch (..most other tablets do NOT have multi-touch), probably just certain Wacom tablets for MacOS. The Artist Pro 16TP display tablet has multi-touch, but it's about 2x as much as a Surface Go 3.

https://www.shapr3d.com/windows

Shapr3D is the fastest if you don't need complex curves (uMake, only available for the ipad is the fastest with complex curves).

If you do need to integrate parts (particularly "off-the-shelf" parts) then you can always transfer over to Fusion 360 for further work on the model.

Unfortunately to achieve that sort of speed requires the use of a pen + tablet w/ *multi-touch, and is only available on ipad, MacOS, and now Windows.

Finally, it's a subscription services for $20 a month - but if you only need a month for your project then it's not exactly expensive.

*for Windows this means a Surface Tablet (or other Windows tablet) or one of the Wacom tablets that has multi-touch (..most other tablets do NOT have multi-touch), probably just certain Wacom tablets for MacOS. The Artist Pro 16TP display tablet has multi-touch, but it's about 2x as much as a Surface Go 3.

https://www.shapr3d.com/windows

Dest.

I'm not sure as to whether your interest is just for a project amp case or generally as a way to further employment, so. If you're a student, try to source an educational copy (very low cost or even free) of an industry common package, Solidworks, Creo, Inventor or some such. This will help in later opportunities. If not, having used these and others I would say that if for your own purchase

Fusion 360 is quite reasonable in performance and cost, (and is free for a year or so trial, I seem to remember), (I've never tried any of the 'Fully Free' ones, though some, as shown above seem really good) also being a good stepping stone.

Unfortunately many licences are now 'rental subscription' so they have you by the 'Beep Beep' on an ongoing basis. I don't know what ones are bought and owned outright anymore. That's a shame because just like operating systems and most other applications in my view 80% to 90% is now fairly well established regarding core functionality, and regular updates aren't really needed. (other than for hardware and driver support).

Cases could probably just be done in 3D solids, (try not to just go 2D in my view) but if as a learning tool, consider sheet metal addons/familiarisation. Surfaces/surfacing is a real advantage (not really needed for audio stuff) but really great if for learning to open up more avenues to employment as the Industrial Design bods love to put compound curves and swoops on everything nowadays. Remember, that though cross application platform translation is possible, some detail tends to be lost, so try to think about your long term goals.

I hope that some of this helps. (Other modules/functions like Thermal, FEA etc are available but lets keep things reasonably simple at this stage!)

R

I'm not sure as to whether your interest is just for a project amp case or generally as a way to further employment, so. If you're a student, try to source an educational copy (very low cost or even free) of an industry common package, Solidworks, Creo, Inventor or some such. This will help in later opportunities. If not, having used these and others I would say that if for your own purchase

Fusion 360 is quite reasonable in performance and cost, (and is free for a year or so trial, I seem to remember), (I've never tried any of the 'Fully Free' ones, though some, as shown above seem really good) also being a good stepping stone.

Unfortunately many licences are now 'rental subscription' so they have you by the 'Beep Beep' on an ongoing basis. I don't know what ones are bought and owned outright anymore. That's a shame because just like operating systems and most other applications in my view 80% to 90% is now fairly well established regarding core functionality, and regular updates aren't really needed. (other than for hardware and driver support).

Cases could probably just be done in 3D solids, (try not to just go 2D in my view) but if as a learning tool, consider sheet metal addons/familiarisation. Surfaces/surfacing is a real advantage (not really needed for audio stuff) but really great if for learning to open up more avenues to employment as the Industrial Design bods love to put compound curves and swoops on everything nowadays. Remember, that though cross application platform translation is possible, some detail tends to be lost, so try to think about your long term goals.

I hope that some of this helps. (Other modules/functions like Thermal, FEA etc are available but lets keep things reasonably simple at this stage!)

R

I should note that uMake is not a solid modeler, while you can push/pull shapes - the model is "hollow", and needs post-processing from a solid modeler to achieve a solid model.(uMake, only available for the ipad is the fastest with complex curves).

Most of the time this is done with something like Meshlab (a "meshing" program), but my guess is that it could be done with a full sculpting program like Nomad Sculpt (..which is incredibly cheap for what it is) via an .obj export file from uMake (to Nomad Sculpt).

uMake is much more difficult to learn relative to Shapr3D (..and it's quite similar to the Nurbs-based "shell" modeling of Fusion 360 - though once you learn it it's still MUCH faster than Fusion 360.) Other than the "non-solid" model, uMake is let-down by some of the "steps" (pen-taps) needed to achieve results that Shapr3D doesn't require, and also an incomplete parametric modeler that's only linear (in time). Still, as previously mentioned uMake has added versatility with shapes that Shapr3D does not have - though I doubt that's important for electronics enclosures (but could be for speaker cabinet design).

Speaking of Fast:

As long as you aren't doing something for profit, TinkerCAD (web-based) is free and is also VERY fast with modeling solid models. (..don't be put-off by the "kiddie" look - the underlying modeling is quite excellent.)

In fact if it's just electronics enclosure modeling I'd probably just use this (if specific parts integration isn't needed).

https://www.tinkercad.com/

It doesn't mean a non-pro friend couldn't do this for you, and charge you nothing.. 😉 (..as a potential means of avoiding certain licensing restrictions.)

You could, anytime, migrate from EAGLE to KiCAD. Anytime, use your Fusion 360 files with other tools.

The great advantage is the ECAD integration of both (pull or push). Support for licensed products is really great, but you‘re right, cloud sucks sometime (also pb after Windows updates). Librairies are easy to manage.

JP

The great advantage is the ECAD integration of both (pull or push). Support for licensed products is really great, but you‘re right, cloud sucks sometime (also pb after Windows updates). Librairies are easy to manage.

JP

- Home

- Design & Build

- Software Tools

- Do you design enclosures in CAD?