Hi!

I´m working on at LOUD-speaker (well not THAT loud, but enough to make some noise at private parties).

Its gonna be a 10" Bass/mid and a "titanium-dome" with a crossover somewhere around 3-4Khz.

I have two decent Titanium domes and I was wondering if I could make a horn of some kind to boost the level? Some of my favorite "small" loud-speakers are the good old EV in the grey "flat" box with a 12" and a treble horn (sorry cant remember the name. Something with 200, -SL200?. I will try to find a picture).

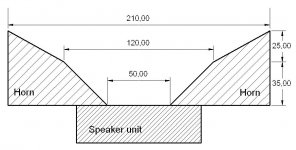

A cross-sction off the horn looks like the attachment. Could I make something like that and place in front of a normal dome-unit? ( I know, that I could... - would it work..?).

I was thinking on making a horn of Styrofoam for a starter. Any ideas?

EDIT: The Electro Voice speaker: http://www.stevesdjservice.com/images/Mar30_03.JPG

TroelsM

I´m working on at LOUD-speaker (well not THAT loud, but enough to make some noise at private parties).

Its gonna be a 10" Bass/mid and a "titanium-dome" with a crossover somewhere around 3-4Khz.

I have two decent Titanium domes and I was wondering if I could make a horn of some kind to boost the level? Some of my favorite "small" loud-speakers are the good old EV in the grey "flat" box with a 12" and a treble horn (sorry cant remember the name. Something with 200, -SL200?. I will try to find a picture).

A cross-sction off the horn looks like the attachment. Could I make something like that and place in front of a normal dome-unit? ( I know, that I could... - would it work..?).

I was thinking on making a horn of Styrofoam for a starter. Any ideas?

EDIT: The Electro Voice speaker: http://www.stevesdjservice.com/images/Mar30_03.JPG

TroelsM

Attachments

A Geddes waveguide

Hello Troels, want to bump & boogie?

You may want to consider for your "horn" profile the following:

y= SQRT(a*2 +Tan*2(theta)(x*2))

where

y = radius of contour

a = throat radius (2.54 cm dome = 1.27 cm)

theta = 1/2 coverage angle (for desired dispersion of 60 degrees, this is 30 degrees)

x = distance from throat

(x*2) means (x squared)

The transition of the horn to the baffle should be with a radius no less than wavelength/4, where wavelength is the upper limit for the horn.

Your depicted "horn" may be adequate for your intentions. I expect it would produce diffractions with freq. resp. effects

I would make the prototype from mdf. I would make the proven version from a select hardwood. If you use syrofoam I would coat the surface to smooth surface irregularities.

I need a routine scripted so I can create the profile described by the equation. My excel skills are lacking. With the profile I can turn it on my wood lathe. Would you like to collaborate?

What tweeters are you considering? Seas units are used by Amphion and others. I would consider the TBFC/G.

Hello Troels, want to bump & boogie?

You may want to consider for your "horn" profile the following:

y= SQRT(a*2 +Tan*2(theta)(x*2))

where

y = radius of contour

a = throat radius (2.54 cm dome = 1.27 cm)

theta = 1/2 coverage angle (for desired dispersion of 60 degrees, this is 30 degrees)

x = distance from throat

(x*2) means (x squared)

The transition of the horn to the baffle should be with a radius no less than wavelength/4, where wavelength is the upper limit for the horn.

Your depicted "horn" may be adequate for your intentions. I expect it would produce diffractions with freq. resp. effects

I would make the prototype from mdf. I would make the proven version from a select hardwood. If you use syrofoam I would coat the surface to smooth surface irregularities.

I need a routine scripted so I can create the profile described by the equation. My excel skills are lacking. With the profile I can turn it on my wood lathe. Would you like to collaborate?

What tweeters are you considering? Seas units are used by Amphion and others. I would consider the TBFC/G.

Hi and thanks for the fast reply.

The eq. seems to be very simple. I hav'nt got any mat-tools on my PC right now, but i could be calculated on a "pocket" calculator (texax 82, and the like).

As i understand it the eq gives curved sides but many horns have flat sides in 2 or 3 different angles, - like my drawing. Why?

I´m going to use some tweeters i have from an old projekt. Its probably 3/4 inch domes. They are not ment to be used as horn-drivers but what the heck...

TroelsM

EDIT: Looking at the eq. i get confused... Is it sqrt(a*2 + tan((2*theta)(x*2)) ?

The eq. seems to be very simple. I hav'nt got any mat-tools on my PC right now, but i could be calculated on a "pocket" calculator (texax 82, and the like).

As i understand it the eq gives curved sides but many horns have flat sides in 2 or 3 different angles, - like my drawing. Why?

I´m going to use some tweeters i have from an old projekt. Its probably 3/4 inch domes. They are not ment to be used as horn-drivers but what the heck...

TroelsM

EDIT: Looking at the eq. i get confused... Is it sqrt(a*2 + tan((2*theta)(x*2)) ?

Yes, it is much easier when done by hand. Let me try again:

should be

y = SQRT(a*2 + (Tan(theta)*2)(x*2))

So easy to mess this up. Use the (Tangent of theta) squared.

Flat sides do not promote a smooth progression of the wavefront away from the diaphragm. Corners (abrupt changes in the profile) generate sound wave difraction which results in distortion of the sound at the listening position.

y= SQRT(a*2 +Tan*2(theta)(x*2))

should be

y = SQRT(a*2 + (Tan(theta)*2)(x*2))

So easy to mess this up. Use the (Tangent of theta) squared.

Flat sides do not promote a smooth progression of the wavefront away from the diaphragm. Corners (abrupt changes in the profile) generate sound wave difraction which results in distortion of the sound at the listening position.

aha...

I can see that the sides should be as smooth as possible, but then I dont get why so many pro horns are made with flat/angled sides? When making the horn in plastic og metal it should be the same amount of work?

I will play around with the "new" eq.

TroelsM

I can see that the sides should be as smooth as possible, but then I dont get why so many pro horns are made with flat/angled sides? When making the horn in plastic og metal it should be the same amount of work?

I will play around with the "new" eq.

TroelsM

Why not just buy a decent little compression driver and a DesignDirectSound fiberglass horn that fits your size requirements? If you can afford it, try a compression driver from Radian. Those can be had on PartsExpress.com but you'll have to look elsewhere for the DDS horns.

I Know that horn speakers are sold at many shops, but it seems to be do-able to make it my self and it would be a lot cheaper and a lot more fun...

TroelsM

TroelsM

I really don't know, but some pro horns are called "diffraction horns"

I think they use the sharp edges purposely diffract the sound to increase the angle of coverage. I get the impression that this is bad for sound quality though. There is a paper on the Peavey site that shows a straight sided horn that they claim is quite good. I'll see if I can find it..

EDIT: Here it is!

http://www.hilberink.nl/codehans/hornqwp1.pdf

I think they use the sharp edges purposely diffract the sound to increase the angle of coverage. I get the impression that this is bad for sound quality though. There is a paper on the Peavey site that shows a straight sided horn that they claim is quite good. I'll see if I can find it..

EDIT: Here it is!

http://www.hilberink.nl/codehans/hornqwp1.pdf

Hi,

the horn in post 1 looks very wide for a treble unit. Depth of 70mm to 90mm is about right for 3kHz but diameter should also be about 80mm to 100mm. That big horn looks more like a badly designed mid horn!.

Try using a tractrix horn. It gives a short horn that meets the front panel at a tangent and looks really nice if turned in wood. There is no corner at the front edge and I've heard that it sounds good with treble units.

the horn in post 1 looks very wide for a treble unit. Depth of 70mm to 90mm is about right for 3kHz but diameter should also be about 80mm to 100mm. That big horn looks more like a badly designed mid horn!.

Try using a tractrix horn. It gives a short horn that meets the front panel at a tangent and looks really nice if turned in wood. There is no corner at the front edge and I've heard that it sounds good with treble units.

The horn in my first post is a pretty accurate model off the horn used in the EV speaker: http://www.stevesdjservice.com/images/Mar30_03.JPG.

I cant hear the lack of treble. They are some very nice speakers!

I dont know what the crossover-freq is, but maybe the horn is there to amplify the lack off mid from the tweeter-unit?

Does anyone have any info on the EV speakers? Datasheet? Units?

TroelsM

I cant hear the lack of treble. They are some very nice speakers!

I dont know what the crossover-freq is, but maybe the horn is there to amplify the lack off mid from the tweeter-unit?

Does anyone have any info on the EV speakers? Datasheet? Units?

TroelsM

Hey wait a mnute...

If you look at the horn in the EV-speakers then you'l see that there is a "foam-plug" in the horn-throat. I actually dont know if the driver is located directly behind this "plug" or if there is more of the horn behind the "plug"?

TroelsM

If you look at the horn in the EV-speakers then you'l see that there is a "foam-plug" in the horn-throat. I actually dont know if the driver is located directly behind this "plug" or if there is more of the horn behind the "plug"?

TroelsM

Posted by Troels: If you look at the horn in the EV-speakers then you'l see that there is a "foam-plug" in the horn-throat. I actually dont know if the driver is located directly behind this "plug" or if there is more of the horn behind the "plug"?

Interesting. Geddes uses 30 ppi acoustic foam in his production speaker as an acoustic filter; mechanical, rather than electrical.

TroelsM -

I've built horns and waveguides for both conventional tweeters and compression drivers. It's easier to get good results with compression drivers, and for the ULTIMATE in performance, compression drivers are simply superior. You would expect this, they're expensive and they're DESIGNED for horn loading.

If you really really want to horn load a dome tweeter, the best results will be found when you use a shallow horn with a very large mouth-to-throat ratio. In other words, something that looks like this:

Have fun.

John

I've built horns and waveguides for both conventional tweeters and compression drivers. It's easier to get good results with compression drivers, and for the ULTIMATE in performance, compression drivers are simply superior. You would expect this, they're expensive and they're DESIGNED for horn loading.

If you really really want to horn load a dome tweeter, the best results will be found when you use a shallow horn with a very large mouth-to-throat ratio. In other words, something that looks like this:

An externally hosted image should be here but it was not working when we last tested it.

Have fun.

John

It works! (maybe...)

Hi!

I´ve build the horn and it seems to be working. I have no gear to test the horn but there seems to be a boost in the mids and a little treble boost.

I'm more and more convinved that the horn is made to boost the mids in such a way that the gab between the woofer and the tweeter is covered. In this way the x-over-freq for the woofer could be say 2500Hz and the the treble x-over-freq could be 3500Hz.

The woofer won't break up as much and the tweeter is loaded less. Does this make any sense?

I have no pictures of the horn just now but i have attached a pic of the cabinet whitout the frontplate. It's made of IKEA-shelfs... maybe not the best material, but it's nice to work with and somebody had to be the first to do it...

TroelsM

Hi!

I´ve build the horn and it seems to be working. I have no gear to test the horn but there seems to be a boost in the mids and a little treble boost.

I'm more and more convinved that the horn is made to boost the mids in such a way that the gab between the woofer and the tweeter is covered. In this way the x-over-freq for the woofer could be say 2500Hz and the the treble x-over-freq could be 3500Hz.

The woofer won't break up as much and the tweeter is loaded less. Does this make any sense?

I have no pictures of the horn just now but i have attached a pic of the cabinet whitout the frontplate. It's made of IKEA-shelfs... maybe not the best material, but it's nice to work with and somebody had to be the first to do it...

TroelsM

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- DIY treble horn?