http://www.diyaudio.com/forums/analogue-source/274529-stripping-down-old-garrard.html

Did you see my record cleaner..

Did you see my record cleaner..

Trade? 🙂

😀😀😀

http://www.diyaudio.com/forums/analogue-source/274529-stripping-down-old-garrard.html

Did you see my record cleaner..

yes i done Joel..

your give me support and Ideas....

regards

ed

"I often think could use part of the printer for the linear tracking tonearm "..

I haven't seen a really good quality linear bearings in printers.. I guess they do exist in good printers..

I haven't seen a really good quality linear bearings in printers.. I guess they do exist in good printers..

Printers don't really need good linear bearings, they're mostly driven by stepper motors with an optical feedback system. If they're noisy, so be it. Tonearm needs quality bearings to keep friction low and noise low.

I'm thinking to use printer. because my assumption printer can be set to it with precision, of course, and feedback from RPM to step attenuator.

turns out it was not good to be a linear tracking.

so the problem is in bearing unfavorable ....

i see.

turns out it was not good to be a linear tracking.

so the problem is in bearing unfavorable ....

i see.

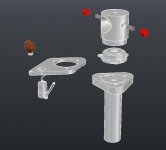

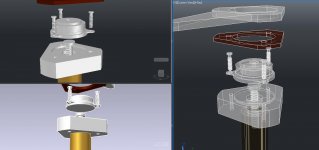

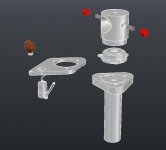

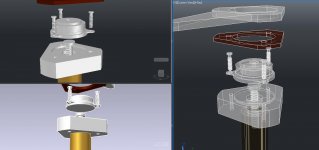

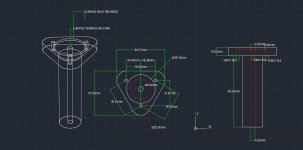

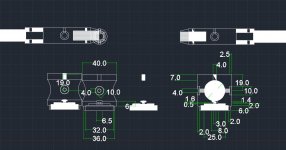

projects that are not done.

if you have bearing from hard drive like this:

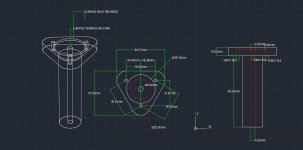

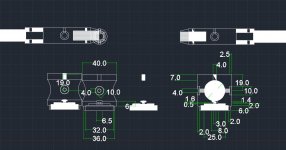

I have drawing but not done because of busy, I just give the picture to be an idea to friends:

link google drive dwg file

bearing sip.dwg - Google Drive

if you have bearing from hard drive like this:

I have drawing but not done because of busy, I just give the picture to be an idea to friends:

link google drive dwg file

bearing sip.dwg - Google Drive

Last edited:

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- DIY Tonearm from part HD computers, why not..?