Hey All,

I'm working on a tonearm design which uses a combination of ball bearings for horizontal movement and spikes for vertical. I will share my ideas for feedback soon.

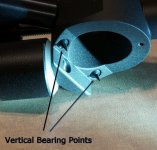

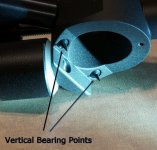

Right now, I need some assistance in sourcing 'spikes' for the vertical bearing. I would like to use something similar to what is used on a Kuzma 4Point tonearm (see below photos). Any ideas?

Having read through existing threads, there are some ideas that might work (football boot spikes for example). However I thought I'd open this one up for any further specific suggestions.

The main criteria from my perspective (in relation to my planned design), is that the spikes need to be small (with a small tip radius) and hard.

Cheers,

Fish

I'm working on a tonearm design which uses a combination of ball bearings for horizontal movement and spikes for vertical. I will share my ideas for feedback soon.

Right now, I need some assistance in sourcing 'spikes' for the vertical bearing. I would like to use something similar to what is used on a Kuzma 4Point tonearm (see below photos). Any ideas?

Having read through existing threads, there are some ideas that might work (football boot spikes for example). However I thought I'd open this one up for any further specific suggestions.

The main criteria from my perspective (in relation to my planned design), is that the spikes need to be small (with a small tip radius) and hard.

Cheers,

Fish

Last edited:

The vintage Zenith "2G" belt drive record changers used a set of "blades" for vertical pivots.

They worked extremely well, were fuss-free, and allowed uninhibited vertical movement of the tonearm.

This is the changer I'm talking about, I sold it last year to a guy who was thrilled with it.

They worked extremely well, were fuss-free, and allowed uninhibited vertical movement of the tonearm.

This is the changer I'm talking about, I sold it last year to a guy who was thrilled with it.

Attachments

Hi, drdarkfish

Depending on skill and tools you can get 1/16" carbide rod ( Ebay) and sharpen them yourself or

Jewel Bearings Introduction – Bird Precision

Good luck,

Joe

Depending on skill and tools you can get 1/16" carbide rod ( Ebay) and sharpen them yourself or

Jewel Bearings Introduction – Bird Precision

Good luck,

Joe

I had a random thought about tungsten being a great material and found these: Tungsten Needle, #2 sharp

Might be an idea - though perhaps too delicate?

Might be an idea - though perhaps too delicate?

ballpoint pen tips

Perhaps a pair of tips from ballpoint pens, with ink drained and cleaned, pointing downward might work? They are precise, low friction, and the allowing of rotary movement might or might not be beneficial. They are certainly cheap to experiment with to find out!

I need some assistance in sourcing 'spikes' for the vertical bearing. I would like to use something similar to what is used on a Kuzma 4Point tonearm (see below photos). Any ideas?

Perhaps a pair of tips from ballpoint pens, with ink drained and cleaned, pointing downward might work? They are precise, low friction, and the allowing of rotary movement might or might not be beneficial. They are certainly cheap to experiment with to find out!

The older line of Dual of turntables (1200 series) had it all figured out with their precision gimble mounting.

I doubt that anyone would consider that design flawed in any way.

I doubt that anyone would consider that design flawed in any way.

Hi drdarkfish,

Look at sewing needles. Some of the sturdier ones may work.

Sincerely,

Ralf

I doubt that, because it's better to use hardened steel to eliminate dulling and wear.

The first issue you need to overcome is alignment of the pins in the cup. If they are not perfectly aligned the pins will ride up the side of the cups.

The Kuzma uses 1 Cup and 1 Vee block so there i no miss alignment. You can see the Vee on the RH side of the photo.

I am a big fan of the Technics style bearings. These are effectively unipivots as the pin engages in the bearing loading all balls preventing rattling.

The other solution is to use horizontal pin pivots, like jewel instruments. I use these on my linear tracker. I made the Vee Cups from M3 set screws and the pins from 1.5mm drill bits.

The Kuzma uses 1 Cup and 1 Vee block so there i no miss alignment. You can see the Vee on the RH side of the photo.

I am a big fan of the Technics style bearings. These are effectively unipivots as the pin engages in the bearing loading all balls preventing rattling.

The other solution is to use horizontal pin pivots, like jewel instruments. I use these on my linear tracker. I made the Vee Cups from M3 set screws and the pins from 1.5mm drill bits.

Attachments

The first issue you need to overcome is alignment of the pins in the cup. If they are not perfectly aligned the pins will ride up the side of the cups.

The Kuzma uses 1 Cup and 1 Vee block so there i no miss alignment. You can see the Vee on the RH side of the photo.

I am a big fan of the Technics style bearings. These are effectively unipivots as the pin engages in the bearing loading all balls preventing rattling.

The other solution is to use horizontal pin pivots, like jewel instruments. I use these on my linear tracker. I made the Vee Cups from M3 set screws and the pins from 1.5mm drill bits.

Hi Warrjon, you've hit the nail on the head (excuse the pun)...

Without going into too much detail, I will indeed be using a combination of a double-cup and Vee-cup trench bearing for the exact reason you mentioned - to ensure no misalignment between spikes.

Furthermore, I intend on sourcing these cups in sapphire, just like Kuzma use on their newer arms. So, in essence, what I am looking for is very much similar to the Kuzma arm.

Where I need help is in sourcing the relevant spikes and also matching their tip radius to a suitable bearing cup.

Ideally if there was a manufacturer which provided both (bearing and matching spike), that would make life a little easier.

I guess the considerations for matching the spike to the cup has to be:

1) that the spike tip sits comfortably at the bottom of the cup, and:

2) the opening radius of the Vee and rounded Cup, is wide enough to allow for the vertical tilting of the arm (if that makes sense) - In other words for the cup to not be too narrow to restrict movement.

Try True Point in the UK Charles is knowledgeable and assisted me in selecting Jewels for an upcoming project.

True Point (UK) Ltd - Precision engineers

True Point (UK) Ltd - Precision engineers

I doubt that, because it's better to use hardened steel to eliminate dulling and wear.

Hello wiseoldtech,

Who says that sewing needles are not heat treated?

Sincerely,

Ralf

Hi

Here is my dual pivot:

Your idea is very close to what I'm working towards.

I'm interested to know:

1. How you machine your parts.

2. What you're using for your horizontal bearing.

Hi, ChrisG139

Very nice !! What type of bearing you use for horizontal movement ?

I second that 🙂 Keen to know what was used as a Horizontal Bearing.

That's actually a very good idea.. I hadn't put my mind to a scribe tip.

Have you used something similar before?

Hi The Spike tip needs to have a tighter angle (sharper) that the cup.

Cheers

Thanks Temaad,

If I understand what you're saying: the angle at which the cup flares out at, needs to be greater than that of the end of the pivot spike, otherwise it wont sit at the base of the cup - right?

I guess the other consideration is not making the cup too large, or allow it to have too greater angle, otherwise the tip of the pivot spike will move freely within the cup (which would be bad).

- Home

- Source & Line

- Analogue Source

- DIY Tonearm: Double Vertical Spikes - Help Needed