I thought I would start a thread to swap ideas for ellipsoidal (or other) reflector designs or sources.

I've been thinking for a while what I really need in my projector is a stage spot light, a decent one which has an ellipsoidal reflector, and a couple of lenses to produce a really nice almost collimated beam.

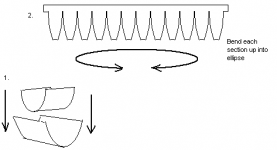

These are likely to be pretty expensive, so I thought there may be a cheap way (even if it takes a fair bit of labour) to make a half decent reflector DIY. A good sheet material to use is thin aluminium formed into shape then polished to a highly reflective surface. One idea that has been mentioned before in this forum is using two bits of sheet formed into ellipsoidal shapes, then one cut to fit inside the other. The other idea I have had is to cut radial sections of the ellipse out of sheet material, then bend each little pie slice into an ellipse, then fold the whole lot around so the ends join and form the final reflector shape. Haven't quite figured out how to hold the thing together yet. Hopefully the picture explains what I mean 😕 🙂

I've been thinking for a while what I really need in my projector is a stage spot light, a decent one which has an ellipsoidal reflector, and a couple of lenses to produce a really nice almost collimated beam.

These are likely to be pretty expensive, so I thought there may be a cheap way (even if it takes a fair bit of labour) to make a half decent reflector DIY. A good sheet material to use is thin aluminium formed into shape then polished to a highly reflective surface. One idea that has been mentioned before in this forum is using two bits of sheet formed into ellipsoidal shapes, then one cut to fit inside the other. The other idea I have had is to cut radial sections of the ellipse out of sheet material, then bend each little pie slice into an ellipse, then fold the whole lot around so the ends join and form the final reflector shape. Haven't quite figured out how to hold the thing together yet. Hopefully the picture explains what I mean 😕 🙂

Attachments

Muzzman,

I think it is a very good idea that you started this thread, the reflector is one area that remains a problem for the majority of us out there building projectors.

I've had a look at your idea for a reflector and I sort of get the idea, but not quite. Any chance you could fashion a rough 3D sketch of the #2 design? The sort of image I'm making in my head of that design is a kind of flower shape - a circle of ellipsoidal leaves - am I completely off track here?

I recently fashioned myself a single-plane ellipsoidal reflector out of the type of material you describe, although the finish of material I bought is called 'brilliant' and is mirror-like. This meant I didn't have to spend hours polishing the surface, but on the flipside, the 2'X4' sheet I bought was four times the price of the equivalent non-mirrored aluminium!

For any UK enthusiasts out there, 'brilliant aluminium' is available in 2'X4' sheets (approx.) at B&Q for around £28. I couldn't find sheets smaller than that.

As for the results with this new reflector, I'm still not convinced that it's working as well as it could. At the moment the ellipsoid aperture is wider than my LCD aperture so I reckon I'm wasting a significant amount of light. I intend to experiment with different reflector apertures to gain more understanding of reflector design and placement.

I have learned that when working with this material you need the right cutting gear. You can quite successfully cut through it with a pair of scissors, but it warps really badly along the cutting edge. A jigsaw, or possibly metal cutting scissors (do these exist?) are more appropriate. I also learnt that it has to be treated carefully - it dents real easy and any dents means random light paths rather than the unfiorm light paths we are all looking for.

James

I think it is a very good idea that you started this thread, the reflector is one area that remains a problem for the majority of us out there building projectors.

I've had a look at your idea for a reflector and I sort of get the idea, but not quite. Any chance you could fashion a rough 3D sketch of the #2 design? The sort of image I'm making in my head of that design is a kind of flower shape - a circle of ellipsoidal leaves - am I completely off track here?

I recently fashioned myself a single-plane ellipsoidal reflector out of the type of material you describe, although the finish of material I bought is called 'brilliant' and is mirror-like. This meant I didn't have to spend hours polishing the surface, but on the flipside, the 2'X4' sheet I bought was four times the price of the equivalent non-mirrored aluminium!

For any UK enthusiasts out there, 'brilliant aluminium' is available in 2'X4' sheets (approx.) at B&Q for around £28. I couldn't find sheets smaller than that.

As for the results with this new reflector, I'm still not convinced that it's working as well as it could. At the moment the ellipsoid aperture is wider than my LCD aperture so I reckon I'm wasting a significant amount of light. I intend to experiment with different reflector apertures to gain more understanding of reflector design and placement.

I have learned that when working with this material you need the right cutting gear. You can quite successfully cut through it with a pair of scissors, but it warps really badly along the cutting edge. A jigsaw, or possibly metal cutting scissors (do these exist?) are more appropriate. I also learnt that it has to be treated carefully - it dents real easy and any dents means random light paths rather than the unfiorm light paths we are all looking for.

James

metal cutting scissors

You mean like Tin Snips? THey will have the same rigid effect as the scisors, I have a swiss pair of them. Anyhow also air tools are nice for that stuff. I ahve a 41/2" cutter grinder wheel that good for it. But others can use a dremel cutter instead, only exception is the dremel wheels last 1/20th as long as real cutter wheels do and are alot slower. But that stuff doesnt sound like it would be thick anyhow.

You mean like Tin Snips? THey will have the same rigid effect as the scisors, I have a swiss pair of them. Anyhow also air tools are nice for that stuff. I ahve a 41/2" cutter grinder wheel that good for it. But others can use a dremel cutter instead, only exception is the dremel wheels last 1/20th as long as real cutter wheels do and are alot slower. But that stuff doesnt sound like it would be thick anyhow.

Vinyljunky, you are spot on with the flower comment.

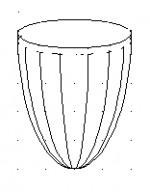

here's a diagram of the #2 design folded together. Imagine all the vertical lines on the ellipse are cut, then the whole thing is unwrapped and folded flat. (obviously build with the reverse procedure!) Need some fancy cad stuff to figure out an accurate template, but I think the cutting would be ok. I have cut aluminium very successfully with a jigsaw. The thin brilliant finish stuff sounds great, just have to use a fine tooth blade on the jigsaw. Provided you make sure it doesn't jam, the sheet doesn't buckle at all. I was thinking of using wooden jigs cut in the right shape to clamp the individual 'leaves' one at a time into an ellipse segment curve. Then wrapping the whole lot around another wooden former to keep the shape while whatever is used to hold it together is put on.

here's a diagram of the #2 design folded together. Imagine all the vertical lines on the ellipse are cut, then the whole thing is unwrapped and folded flat. (obviously build with the reverse procedure!) Need some fancy cad stuff to figure out an accurate template, but I think the cutting would be ok. I have cut aluminium very successfully with a jigsaw. The thin brilliant finish stuff sounds great, just have to use a fine tooth blade on the jigsaw. Provided you make sure it doesn't jam, the sheet doesn't buckle at all. I was thinking of using wooden jigs cut in the right shape to clamp the individual 'leaves' one at a time into an ellipse segment curve. Then wrapping the whole lot around another wooden former to keep the shape while whatever is used to hold it together is put on.

Attachments

Muzzman, thats along the lines of what I was thinking too. But how are you placeing the bulb? The other problem I had about it was that the hole deseign is ment to make parallel light source right? Well then wouldnt the outside edge of reflector have to be close to the size of lcd panel if not a smidge larger as to make use of all the light. My thought is that the bulb may be too big to allow this, also how close can a reflector be in that situation without overheating the bulb? Guess you could figure a way to use a fan on it to fix that, dunno. Its a great idea though!

Wally,

That reflector certainly would be usable, but a couple of points:

1) What sort of LCD source are you using? Considering that the reflector has a diameter of 14", you would ideally be using a 14" or larger LCD in order to make use of all your light. I guess that this means you would have to mod a flatscreen monitor, or somesuch, and everyone who reads this forum at all knows how difficult (impossible in some cases) it is to seperate the controller and cold cathode from the LCD section. Even so, I guess it would be possible to modify the reflector - resize the aperture and move the bulb along its axis , but since it was designed with a specific focal length I reckon modification would be inefffective.

2)Price. That thing looks expensive and that puts me off straight away. Maybe you are willing to spend alot more! Do you happen to know how much it costs? I have already spend £270 on my projector and am reluctant to spend any more!

Muzzman,

I am very excited by your design, if you could pull it off you may be on to a winner! I had a thought for the future, if you do manage to create such a beast: Rather than making the actual reflector from the 'flower' design, you could make a mould with that flower, from which a reflector could be poured with some cheap material which would then be sprayed with a highly reflective (aluminium?) paint. This would mean that you would have eliminated light path problems at the points where each 'leaf' meets. This is probably a bit over enthusiatic, but I can't halp it 😀

James

That reflector certainly would be usable, but a couple of points:

1) What sort of LCD source are you using? Considering that the reflector has a diameter of 14", you would ideally be using a 14" or larger LCD in order to make use of all your light. I guess that this means you would have to mod a flatscreen monitor, or somesuch, and everyone who reads this forum at all knows how difficult (impossible in some cases) it is to seperate the controller and cold cathode from the LCD section. Even so, I guess it would be possible to modify the reflector - resize the aperture and move the bulb along its axis , but since it was designed with a specific focal length I reckon modification would be inefffective.

2)Price. That thing looks expensive and that puts me off straight away. Maybe you are willing to spend alot more! Do you happen to know how much it costs? I have already spend £270 on my projector and am reluctant to spend any more!

Muzzman,

I am very excited by your design, if you could pull it off you may be on to a winner! I had a thought for the future, if you do manage to create such a beast: Rather than making the actual reflector from the 'flower' design, you could make a mould with that flower, from which a reflector could be poured with some cheap material which would then be sprayed with a highly reflective (aluminium?) paint. This would mean that you would have eliminated light path problems at the points where each 'leaf' meets. This is probably a bit over enthusiatic, but I can't halp it 😀

James

Well, Altman makes a 10" model and I've found a theater rental place online that i selling old ones for $20. I haven't got any response from them yet but we'll see.

Willy,

Those numbers sound very promising. 10" is much more appropriate. I would definitely be interested in one at that price! Keep us posted.

James

Those numbers sound very promising. 10" is much more appropriate. I would definitely be interested in one at that price! Keep us posted.

James

Car reflector?

Hopefully this doesn't sound too ignorant--but wouldn't a high-power bulb from a vehicle work? If you could find a wrecked lexus or similar with the high-power bulbs, would you be able to use it in a projector? I do realize the lamps require a high-power 12v power source, which may not be easy or cheap to come by--but the reflectors from auto lamps or the actual automobile may work.

Or, you could at least use the reflection device from a car's headlights. Some of them are even rectangular & parabolic (which would lend itself well to projecting a rectangular lcd screen). Like I said, I'm very new to this, and most of it is over my head--but would this "solution" have any possibilities?

Thanks,

Anthony

Hopefully this doesn't sound too ignorant--but wouldn't a high-power bulb from a vehicle work? If you could find a wrecked lexus or similar with the high-power bulbs, would you be able to use it in a projector? I do realize the lamps require a high-power 12v power source, which may not be easy or cheap to come by--but the reflectors from auto lamps or the actual automobile may work.

Or, you could at least use the reflection device from a car's headlights. Some of them are even rectangular & parabolic (which would lend itself well to projecting a rectangular lcd screen). Like I said, I'm very new to this, and most of it is over my head--but would this "solution" have any possibilities?

Thanks,

Anthony

parabolic is good. And your right why! A car type parabolic is good as it already projects light into a similar shape as the screen. Thus using most of the light. Have you noticed though that car lights also dont have a absolute beam either. Like when driving you can see a deer in the feild way off the the right. The lights are pointing forward. Thats pretty wide beam really. Its just most intense at the center. I see what you are sayng, reg. parabolic type has been bright up before. But in your case I see two problems. #1 a car bulb is not bright enuff. Not even close to bright enuff really. So you would need atleast two. Then you have the problem of combining two or more lights into one beam. So then you have the just reflector BUT these MH bulbs most are using are too large too use a smaller reflector like that. Also since the bulb is now not placed in the reflectors focus point now it will change how the reflector works. Thus not being a usefull reflector any more. So if you could find a really big say 8-10" metal reflector just like a car has - you prob. got a really great reflector.

So reflector you mentioned is ok, but size is bad (if you were to change to MH). The bulbs not bright enuff thats in it either.

I may be wrong, some other here are more experienced in this, but thats just my thoughts on it. 🙂

So reflector you mentioned is ok, but size is bad (if you were to change to MH). The bulbs not bright enuff thats in it either.

I may be wrong, some other here are more experienced in this, but thats just my thoughts on it. 🙂

I assumed. . .

That's kind of what I thought, but I wasn't sure if the reflective devices in the more expensive cars would have some worth.

Thanks for the quick reply!

That's kind of what I thought, but I wasn't sure if the reflective devices in the more expensive cars would have some worth.

Thanks for the quick reply!

headlight reflectors

My first thought was to use a car headlight assembly as well. Did a bit of thinking about it, basically there are two sorts. Older ones are parabolic, some newer ones are called 'projector' headlights and are elliptic. Sounds great, but the max headlight power you will find is about 100W halogen, so you need to replace the globe with another light source and try to maintain the focus. I was thinking of putting the 10000 lumen 250W slide projector globe I use into a headlight reflector, it is small enough, and I could provide fine adjustment to move it into just the right position by trial and error. However I think the beam spread on even the fancy (expensive) headlight assemblies would be too big. Maybe ok for bigger lcd's using fresnel lenses.

Another point to bear in mind with all reflector designs is the correct orientation of the bulb. If a bulb is designed to be used vertically, and it is used horizontally, then the life will be drastically reduced.

My first thought was to use a car headlight assembly as well. Did a bit of thinking about it, basically there are two sorts. Older ones are parabolic, some newer ones are called 'projector' headlights and are elliptic. Sounds great, but the max headlight power you will find is about 100W halogen, so you need to replace the globe with another light source and try to maintain the focus. I was thinking of putting the 10000 lumen 250W slide projector globe I use into a headlight reflector, it is small enough, and I could provide fine adjustment to move it into just the right position by trial and error. However I think the beam spread on even the fancy (expensive) headlight assemblies would be too big. Maybe ok for bigger lcd's using fresnel lenses.

Another point to bear in mind with all reflector designs is the correct orientation of the bulb. If a bulb is designed to be used vertically, and it is used horizontally, then the life will be drastically reduced.

nother crazy idea

okay, here we go again.

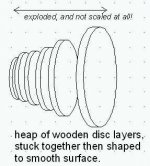

What about this for diy elliptical reflector of whatever dimensions you need?

1/ Design what you want on pc

2/ Cut out a series of wooden circular discs from mdf to form the crude shape.

3/ Stick or bolt these together so you have a rough jaggy shape of the reflector,

4/ smooth this out with a surform file or better yet a lathe.

5/ Lacquer it so its nice and smooth

6/ Spray it with silicon spray or something to act as a mould release agent

7/ Paper mache style wrap pieces of aluminium foil around, glueing quite a few layers to give it some strength, taking a lot of care with the bottom layer to avoid too many wrinkles

8/ maybe glue some other non-flammable material to the outside to mechanically brace it.

9/ Wait for it to dry and slide out the wooden lump in the middle and a-voila!

Of course its easier if you have one prepared earlier 😀

It's hard to find time at the moment to try these ideas out, but this one may just work...

I would also allow room in the mould for the light fixture, and air inlet and outlet points to force airflow over the reflector and bulb surfaces.

okay, here we go again.

What about this for diy elliptical reflector of whatever dimensions you need?

1/ Design what you want on pc

2/ Cut out a series of wooden circular discs from mdf to form the crude shape.

3/ Stick or bolt these together so you have a rough jaggy shape of the reflector,

4/ smooth this out with a surform file or better yet a lathe.

5/ Lacquer it so its nice and smooth

6/ Spray it with silicon spray or something to act as a mould release agent

7/ Paper mache style wrap pieces of aluminium foil around, glueing quite a few layers to give it some strength, taking a lot of care with the bottom layer to avoid too many wrinkles

8/ maybe glue some other non-flammable material to the outside to mechanically brace it.

9/ Wait for it to dry and slide out the wooden lump in the middle and a-voila!

Of course its easier if you have one prepared earlier 😀

It's hard to find time at the moment to try these ideas out, but this one may just work...

I would also allow room in the mould for the light fixture, and air inlet and outlet points to force airflow over the reflector and bulb surfaces.

Attachments

a reflector with oval and parallel Beam, d= ~30cm or ~45cm?

How would a reflector with oval and parallel Beam (better for 16:10) look?

That should be theoretically possible.

I look for a large reflector, but I know never whether he also really parallel light sends.

Where do I find a large (d=~30cm or d=~45cm) reflector with parallel light (ellipsoid for no light loss)? I do not find.

How would a reflector with oval and parallel Beam (better for 16:10) look?

That should be theoretically possible.

I look for a large reflector, but I know never whether he also really parallel light sends.

Where do I find a large (d=~30cm or d=~45cm) reflector with parallel light (ellipsoid for no light loss)? I do not find.

- Status

- Not open for further replies.

- Home

- General Interest

- Everything Else

- The Moving Image

- DIY Projectors

- DIY Reflectors