I'm putting together an H frame OB combo based on MJK's build from some number of years ago. Its 20X20" "plate" or baffle is propped up by a rectangular base of on-edge oriented plywood. I chose to use one of the speaker cutout platters, cut in half for the base of each board.

Just by handling it during construction, I could tell the plank assembly had some real ring to it. Giving it a knock test made me uneasy about mounting the drivers just yet. So I attempted to deaden the panel with materials I have on hand. Lucky me picked up a large salvage roll of ~1/4" cork at a garage sale, figuring I might use it for something...

I've read cork is a good damping material, so I attached a couple rectangular sections (one is 8X18.75", the other 6X18.75" with a cut to avoid the driver position on the panel. This didnt seem to do much, knockwise...which was disappointing.

So I backed those with some 5/8" MDF I had left over from another project. The assembly is glued together using Elmer's Construction. Checking it out after the adhesive just setup, I could hear a clear impact on the panel resonance from knocking on it. One piece covers the larger cork pad, the other uses 3 individual pieces. So the layup is 3/4" ply, 1/4" cork, 5/8" MDF.

That's getting pretty thick. I'd like to imagineer a baffle board that is both thin and non resonant. I'd be willing to go as far as suspending a material within a 20X20" frame, if that's what it takes as a solution. I'd also like to explore construction of a composite board, such as the ply-cork-MDF I hacked together, but at a better thickness regarding driver mounting.

Any and all ideas welcome! I realize there's other threads where people ar doing R&D on this. I think that's for a closed box; this is for OB - as a baffle, it doesnt have all 4 edges fastened to a heavy structure. More like a rectangular plate pinned on one end. As I mentioned, I noticed a lot of ringing in the simple plywood structure I've built.

Just by handling it during construction, I could tell the plank assembly had some real ring to it. Giving it a knock test made me uneasy about mounting the drivers just yet. So I attempted to deaden the panel with materials I have on hand. Lucky me picked up a large salvage roll of ~1/4" cork at a garage sale, figuring I might use it for something...

I've read cork is a good damping material, so I attached a couple rectangular sections (one is 8X18.75", the other 6X18.75" with a cut to avoid the driver position on the panel. This didnt seem to do much, knockwise...which was disappointing.

So I backed those with some 5/8" MDF I had left over from another project. The assembly is glued together using Elmer's Construction. Checking it out after the adhesive just setup, I could hear a clear impact on the panel resonance from knocking on it. One piece covers the larger cork pad, the other uses 3 individual pieces. So the layup is 3/4" ply, 1/4" cork, 5/8" MDF.

That's getting pretty thick. I'd like to imagineer a baffle board that is both thin and non resonant. I'd be willing to go as far as suspending a material within a 20X20" frame, if that's what it takes as a solution. I'd also like to explore construction of a composite board, such as the ply-cork-MDF I hacked together, but at a better thickness regarding driver mounting.

Any and all ideas welcome! I realize there's other threads where people ar doing R&D on this. I think that's for a closed box; this is for OB - as a baffle, it doesnt have all 4 edges fastened to a heavy structure. More like a rectangular plate pinned on one end. As I mentioned, I noticed a lot of ringing in the simple plywood structure I've built.

Last edited:

I'd like to imagineer a baffle board that is both thin and non resonant.

Here is a slightly insane proposition: use a thin sheet of lead. You would need to clamp the driver mounting area between two pieces of a more rigid material, and your baffle would need to permanently hang from a stand, but it should be quite effective

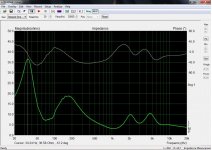

I always thought that resonance should not be a problem with open baffles since they are ...open. I mean in closed boxes it's standing waves that propagate resonances. That said an H frame adds load if I understand correctly MJK. But do they hold standing waves? I attach the impedance curve of my H frame. It shows some glitches bellow 200Hz but I haven't concluded about the cause. Where should resonance appear from a 25mm MDF?

Attachments

There was an attempt...

... a popular Reddit sub. Ding-dong! Well maybe I couldnt use the 20X20 panels as a doorbell; I think my treatment did some good; made them better than just the naked plywood.

Thinking it would have been better if I covered the entire back surface uninterrupted and if I needed to do it again, not using scraps I had on hand...

I know I need to flare the back of the cutout, which is a necessity I'd hope to avoid in a new design. Something I'll need to figure out how to do, while accommodating a previous mistake on these boards.

I'm at a loss when it comes to adhesive. Wood / paper laminates I could use the Elmer's. Unsure what I'd use for plastic, rubber or metal to wood - which I expect will be the face of the board. Elmer's dries had. Should the adhesive be flexible? As in even the adhesive dissipates energy?

Thanks,

... a popular Reddit sub. Ding-dong! Well maybe I couldnt use the 20X20 panels as a doorbell; I think my treatment did some good; made them better than just the naked plywood.

Thinking it would have been better if I covered the entire back surface uninterrupted and if I needed to do it again, not using scraps I had on hand...

I know I need to flare the back of the cutout, which is a necessity I'd hope to avoid in a new design. Something I'll need to figure out how to do, while accommodating a previous mistake on these boards.

I'm at a loss when it comes to adhesive. Wood / paper laminates I could use the Elmer's. Unsure what I'd use for plastic, rubber or metal to wood - which I expect will be the face of the board. Elmer's dries had. Should the adhesive be flexible? As in even the adhesive dissipates energy?

Thanks,

Attachments

Last edited:

So I walked up to the plate and took a swing! Had to try out my new router...

I went in ~1/2 on 3/4, mostly because the router bit kept digging its way out of the collet, before I realized what the backing nut did. Anyway, I put a 7" X 1/4" circular piece of rubber stall mat (picked up from the local farm supply store for another project) into the baffle, securing it with a polymer construction adhesive.

Mounting the drivers on this "suspension", with the intent to isolate their vibration from ringing the plywood panel. I believe its effective - and I could have gone to an 8" cutout without the drivers sagging using this material. Here's photos -

The inside of the cutout need to be finished off with black satin paint. Had to listen first! :')

I went in ~1/2 on 3/4, mostly because the router bit kept digging its way out of the collet, before I realized what the backing nut did. Anyway, I put a 7" X 1/4" circular piece of rubber stall mat (picked up from the local farm supply store for another project) into the baffle, securing it with a polymer construction adhesive.

Mounting the drivers on this "suspension", with the intent to isolate their vibration from ringing the plywood panel. I believe its effective - and I could have gone to an 8" cutout without the drivers sagging using this material. Here's photos -

The inside of the cutout need to be finished off with black satin paint. Had to listen first! :')

Attachments

Last edited: