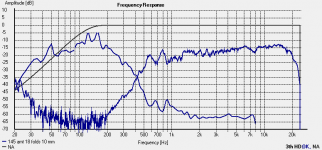

Heres a measurement from one of the paper amts

10 deep pleat (since the fold is triangle only 8 mm effective or something)

gap is 40mm open frame so just 2 metal bars like a normal ribbon except the magnets direction is different ofcourse.

the thing is 140 mm high, i used 6 x 40x20x5 magnets the cheap ones 🙂

its a little harder to get the res down, since the paper is kind of stiff. but i recon increasing the length helps. and also helps to increase impedance. i am aprtically fond of the high end it performs as good as the rubbanoide in distortion wise but extends more and is far more flat.

no smoothing used

10 deep pleat (since the fold is triangle only 8 mm effective or something)

gap is 40mm open frame so just 2 metal bars like a normal ribbon except the magnets direction is different ofcourse.

the thing is 140 mm high, i used 6 x 40x20x5 magnets the cheap ones 🙂

its a little harder to get the res down, since the paper is kind of stiff. but i recon increasing the length helps. and also helps to increase impedance. i am aprtically fond of the high end it performs as good as the rubbanoide in distortion wise but extends more and is far more flat.

no smoothing used

Attachments

hmmm i notice here the high does not extend to 20khz it does in another measurement .. aaah well maybe post another later 🙂 just playing around 🙂 some more

anyone have an idea to soften paper permanently ? for isntance if its wet it is really sloppy might there be a permanent way that wetten's the paper? or soften it ? since i could apply that on the fould lines and could get the resonance down

anyone have an idea to soften paper permanently ? for isntance if its wet it is really sloppy might there be a permanent way that wetten's the paper? or soften it ? since i could apply that on the fould lines and could get the resonance down

Last edited:

I've tried to find the information in the thread but failed.

What was that 40 µm aluminium tape again? Is the 40 µm including the adhesive?

Can you share a link?

maskingshop.co.uk has 40micron alu tape in all sizes. but most alu tape is 40 micron to be honest.

I got a 50mm from Biltema and a 100mm from a plumber store.

The store is Sanistål here in Denmark.

As wrinex wrote Masking shop has it too.

Bernt

The store is Sanistål here in Denmark.

As wrinex wrote Masking shop has it too.

Bernt

hmmm i notice here the high does not extend to 20khz it does in another measurement .. aaah well maybe post another later 🙂 just playing around 🙂 some more

anyone have an idea to soften paper permanently ? for isntance if its wet it is really sloppy might there be a permanent way that wetten's the paper? or soften it ? since i could apply that on the fould lines and could get the resonance down

Getting accurate measurements up this high is not easy. There very well may be content up that high. BUt microphone placement makes it hard to pick it up.

Very nice response from both the diaphragms.

Thanks, then I know.I got a 50mm from Biltema and a 100mm from a plumber store.

The store is Sanistål here in Denmark.

As wrinex wrote Masking shop has it too.

Bernt

Didn't realize that those tapes were that thin.

Couldn't find the specifications at neither the masking shop nor Biltema.

With that relatively thick aluminium foil, the pleats are more likely not to break up.

Was it hard to get the liner off from the tape?

Regarding the harshness that you perceive; I guess that you're applying some EQ?

Thanks, then I know.

Didn't realize that those tapes were that thin.

Couldn't find the specifications at neither the masking shop nor Biltema.

With that relatively thick aluminium foil, the pleats are more likely not to break up.

Was it hard to get the liner off from the tape?

Regarding the harshness that you perceive; I guess that you're applying some EQ?

Masking shop 🙂

• 40 Micron Aluminium Foil with Acrylic Adhesive

• Good Temperature resistant up to 150°C

• Excellent barrier against humidity and vapour

• Conducts heat very well

oh they got even up to 250mm 🙂

Last edited:

Liner comes off easy.

I place the tape with the aluside on the cutting mat.

I think my magnet assembly makes some unwanted reflections.

Will test in my "kithara" magnetsystem.

Cut settings are :knife 3 speed 2 thickness 28

I dont use EQ at measurements.

I dont use it for my amts at all.

Bernt

I place the tape with the aluside on the cutting mat.

I think my magnet assembly makes some unwanted reflections.

Will test in my "kithara" magnetsystem.

Cut settings are :knife 3 speed 2 thickness 28

I dont use EQ at measurements.

I dont use it for my amts at all.

Bernt

i think he meant you can eq the harshness away. could also be with damping clots of any sort, i always find that a nicer solution becaus it damps the membrane to and ussually you get rid of other abnormal peaks and dips to. try stuffing some felt into the backside an you wil know. usualy stuff changes in the distortion department.

although with this design stuffing might cripple since stuffing tends to first attack the very high frequency in output something you dont want to lose, but you want to lose it a bit lower 🙂

i keep being amazed how low you can go!

although with this design stuffing might cripple since stuffing tends to first attack the very high frequency in output something you dont want to lose, but you want to lose it a bit lower 🙂

i keep being amazed how low you can go!

Last edited:

anyone have an idea to soften paper permanently ? for isntance if its wet it is really sloppy might there be a permanent way that wetten's the paper? or soften it ? since i could apply that on the fould lines and could get the resonance down

I would try as experiment my magic bullet for paper woofers, which is dammar varnish: that way we stay in the organic world. Probably the varnished paper will end being stiffer but more elastic at a time, which could be compensated by choosing thinner paper...even W.C. paper 😀like some mate that made some headphones with it years ago...probably the pleats will be rounder and nicer...

The trouble is that it take weeks to be completely dry 😡 so better make several samples and then taste them and compare.

Cheers,

M.

I would try as experiment my magic bullet for paper woofers, which is dammar varnish: that way we stay in the organic world. Probably the varnished paper will end being stiffer but more elastic at a time, which could be compensated by choosing thinner paper...even W.C. paper 😀like some mate that made some headphones with it years ago...probably the pleats will be rounder and nicer...

The trouble is that it take weeks to be completely dry 😡 so better make several samples and then taste them and compare.

Cheers,

M.

Hmm wel the thing is i like to use the paper as it is since it is already laminated I clean the colour gue of it shove it into my printer and etch it 🙂 the fold lines are dictated by the printer ink and the aluminum , so folding does not need a jig 🙂

OK. 😱

The fact is I can hardly imagine how you guys are doing this. 😀

But expecting great things anyway!

Best wishes,

M.

The fact is I can hardly imagine how you guys are doing this. 😀

But expecting great things anyway!

Best wishes,

M.

Masking shop 🙂

• 40 Micron Aluminium Foil with Acrylic Adhesive

• Good Temperature resistant up to 150°C

• Excellent barrier against humidity and vapour

• Conducts heat very well

oh they got even up to 250mm 🙂

Thanks, I still can't find it on the sites though.

Liner comes off easy.

I place the tape with the aluside on the cutting mat.

I think my magnet assembly makes some unwanted reflections.

Will test in my "kithara" magnetsystem.

Cut settings are :knife 3 speed 2 thickness 28

I dont use EQ at measurements.

I dont use it for my amts at all.

Bernt

Thanks for the cutter information. Now I know how you do it.

Yes, reflections should be kept at a minimum. Not only do they show up at frequencies representing the multiples of the wavelength they consists of but also actually causes an "echo" that generates all kinds of inter modulation products.

Yes, that rise towards higher frequencies will for sure sound harsh otherwise.i think he meant you can eq the harshness away.

Here it is:The Making Shop - Helping You Mask For Less - Tapes and Discs - Silicone Tapes - Caps and Plugs

Have some measurements to post, but it is springtime, outdoor there is a lot of work too.

Bernt

Have some measurements to post, but it is springtime, outdoor there is a lot of work too.

Bernt

Aha, it was one level up!Here it is:The Making Shop - Helping You Mask For Less - Tapes and Discs - Silicone Tapes - Caps and Plugs

Have some measurements to post, but it is springtime, outdoor there is a lot of work too.

Bernt

Thank you.

Yes. Details in the other thread.Hi Solhaga.

Did you ever try the folio I sent you?

15-40-3 60'

15-40-3 kit.

12-10-2 60'

12-10-2 kit.

Above are 40x32x7mm.measured at 1m. 2.8v.

12-10-2 kit. are:12my mylar ,10my alu , 2 coils. kitharo magnet system. 60' is magnets angled 60'

Bernt

Last edited:

one thing

for anyone interested in alu foil

Aluminiumfolie Zelfklevend | Aluminiumfolie.nl

30 micron and 50 and 100 50 cm wide! eat your heart out 🙂

just posted it in the threads that might be able to make use of it 🙂

for anyone interested in alu foil

Aluminiumfolie Zelfklevend | Aluminiumfolie.nl

30 micron and 50 and 100 50 cm wide! eat your heart out 🙂

just posted it in the threads that might be able to make use of it 🙂

Just one more .

[/url][/IMG]

12-10-1 kit. 1,2 ohm diff. spl. range

Bernt

that one looks nice 🙂!

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Diy AMT