It is very difficult to fit the to layers over each other within 0,5mm.

Got my 10 and 15 my. mylar by airmail from England.

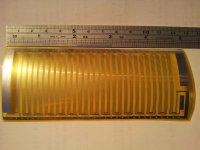

Makes 32x88x5mm double coil diaphragm , one from 10my and one from 15 my.mylar ,to fit in my new aluminium frames.

Likes to see pro layouts. One with three "coils".

Bernt

Got my 10 and 15 my. mylar by airmail from England.

Makes 32x88x5mm double coil diaphragm , one from 10my and one from 15 my.mylar ,to fit in my new aluminium frames.

Likes to see pro layouts. One with three "coils".

Bernt

Last edited:

I'll say one thing about the "Pro" layouts. You are getting very good results with your own work. In fact your low end is better than anything else available until I release my latest version. So truly your work is better than what is currently available.

Your motor is strong and this pushes the balance in your favor to achieve a smooth response and low fs.

The tradeoff is complex assembly and difficult impedance loads.

Your motor is strong and this pushes the balance in your favor to achieve a smooth response and low fs.

The tradeoff is complex assembly and difficult impedance loads.

Fuuuuuuuuuuuck!!!!!!!

Just folded and baked two membranes,. good.

Seamed to be different than my other double coil models.

[/url][/IMG]

[/url][/IMG]

Folded wrong way. trace is turning on pleat , not on top.

Going to make a new.

This time 32x88x7mm.Easyer to compare with my latest models.10 my mylar.

Bernt

Just folded and baked two membranes,. good.

Seamed to be different than my other double coil models.

Folded wrong way. trace is turning on pleat , not on top.

Going to make a new.

This time 32x88x7mm.Easyer to compare with my latest models.10 my mylar.

Bernt

I have pulled some big mistakes before to.

A person who makes no mistakes makes no things!

oh nice, then i might finish something in the next 2 years 😉

*G* Nothing died, other than some time and some self confidence. 😉 Stick it on the wall above the bench with a "DUH!" note as a 'fail safe' reminder....

Still lurking, watching y'alls progress. Nothing short of awesome, guys. *S* Ever upwards...

Still lurking, watching y'alls progress. Nothing short of awesome, guys. *S* Ever upwards...

I just had to remove bamboo veneer off of a custom cabinet that I am making for a client.

I spent half a day working to remove it with a belt sander.

The problem came from another mistake. Working with a vacuum press when tired and I blew out the vacuum bag.

Only $300 mistake.

Never mind the bamboo veneer and all my time.

Like I said.

You will never make mistakes if you keep your hands in your pockets.

But you will also miss out in life's most important gifts.

Making and enjoying the work you have accomplished.

The mistakes are what separate the men from the boys.

It takes a real man to fix them. Not run away from them or give up on the project.

I spent half a day working to remove it with a belt sander.

The problem came from another mistake. Working with a vacuum press when tired and I blew out the vacuum bag.

Only $300 mistake.

Never mind the bamboo veneer and all my time.

Like I said.

You will never make mistakes if you keep your hands in your pockets.

But you will also miss out in life's most important gifts.

Making and enjoying the work you have accomplished.

The mistakes are what separate the men from the boys.

It takes a real man to fix them. Not run away from them or give up on the project.

🙂 thx m8 then im on the right track. haha

ofcourse it is true, but wathing diyaudio or other sources makes you wonder sometimes if you ever gone get something usefull out of all the trial and error 🙂 even if i give up it is for only a few days or weeks max 🙂 haha

Nice job Bernt !!! next one will be ok ! at least they looked good

ofcourse it is true, but wathing diyaudio or other sources makes you wonder sometimes if you ever gone get something usefull out of all the trial and error 🙂 even if i give up it is for only a few days or weeks max 🙂 haha

Nice job Bernt !!! next one will be ok ! at least they looked good

looking good Bernt!! i admire your persistence !!! and very clean as always ! keep them coming ! i might look in the material myself when i finally got myself a new home,and some old projects finished 🙂

Measurements..

First res freq. All diaphragms are 90x32mm and with 40my double coil.

[/url][/IMG]

[/url][/IMG]

390 Hz 5mm deep and 15my mylar.

[/url][/IMG]

[/url][/IMG]

265 Hz. 5mm. 10my.

[/url][/IMG]

[/url][/IMG]

260 Hz. 7mm 15my.

[/url][/IMG]

[/url][/IMG]

183 Hz. 7mm 10my.

Next is freq. responce.

Bernt

First res freq. All diaphragms are 90x32mm and with 40my double coil.

390 Hz 5mm deep and 15my mylar.

265 Hz. 5mm. 10my.

260 Hz. 7mm 15my.

183 Hz. 7mm 10my.

Next is freq. responce.

Bernt

Measured at 30cm distance.

[/url][/IMG]

[/url][/IMG]

5mm deep 15my mylar. on axis

[/url][/IMG]

[/url][/IMG]

5mm. 10my on axis

[/url][/IMG]

[/url][/IMG]

7mm. 15my off axis

[/url][/IMG]

[/url][/IMG]

7mm. 10 my. off axis.

Bernt

5mm deep 15my mylar. on axis

5mm. 10my on axis

7mm. 15my off axis

7mm. 10 my. off axis.

Bernt

Do I understand this correctly that the 7mm deep pleated diaphragm has a rising off axis high frequency response?

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Diy AMT