Hi tinitus

I hate the short ribbons from about 50cm because the bad vertical dispersion.

Maybe that was your problem in comparing the 2 ribbons you build.

Rob

Ehh, the short one I built was 4feet, which would be like 1.2meter

The big one was like 1.8meter

The big one was difficult to control

It also seemed like it was hanging, due to its higher weight from being longer and wider

If you really want such a big thing I dont see any other way than a planar

That on the other hand might be crossed much lower

An old drawing just to illustrate, I wouldnt do it exactly like that

Attachments

Last edited:

Hi Casey

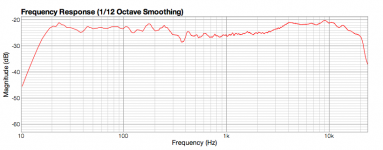

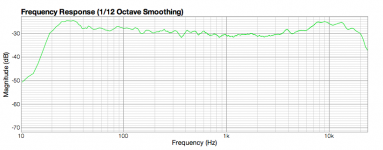

I notice how you damped your ribbon and I tried that and I get away the 8Khz problem allot but not the 1Khz problem.

You can get rid of the 1Khz problem with a notch filter.

So you can get it right with damping for the 8Khz peak and a notch for the 1Khz peak.

But i hear when I use a notch filter so first I want to try another ribbon who is symmetrical at front and back.

If I measure the smaller ribbons I build I don't see those problems.

I compare those 2 types and decide what's best.

Rob

Thanks.That is why I spent so much time layering up my felt dampening in a way that eliminated parallel surfaces behind the ribbon. 😀

Awesome job by the way.

Casey

I notice how you damped your ribbon and I tried that and I get away the 8Khz problem allot but not the 1Khz problem.

You can get rid of the 1Khz problem with a notch filter.

So you can get it right with damping for the 8Khz peak and a notch for the 1Khz peak.

But i hear when I use a notch filter so first I want to try another ribbon who is symmetrical at front and back.

If I measure the smaller ribbons I build I don't see those problems.

I compare those 2 types and decide what's best.

Rob

Hi tinitus

You can control them to use tension weights and 2 ribbon supports along the height.

The one I build in this topic has no supports at all and still have no problem.

The usable crossover depends on linearity and distortion.

Usually the bigger the ribbon the lower crossover point possible.

Rob

I don't have those problems.The big one was difficult to control

It also seemed like it was hanging, due to its higher weight from being longer and wider

You can control them to use tension weights and 2 ribbon supports along the height.

The one I build in this topic has no supports at all and still have no problem.

The usable crossover depends on linearity and distortion.

Usually the bigger the ribbon the lower crossover point possible.

Rob

Hi tinitus

I don't have those problems.

No, not if you limit it mechanically

Personally I dont like that

Streching a ribbon is not the best way

All ribbons have certain ressonance problems at their attached ends

When you support a long ribbon in two other places its like having 3 stacked shorter ribbons

And you will have 6x attached ends, instead of 2

Even more ressonance problems, and now closer to listening height

Anyway, I believe its more the width that determines how low it goes

Maybe to some extend also the length, but much less

Well, maybe more realistically both the length and width

But width is a real hurdle to a ribbon

A major issue is still the design with a wide magnet gap, which places the ribbon in a "tunnel"

Consider it like a throath on a compression driver

We cant suddenly ignore the obvious diffraction problems on hand

It may still work ok, but I believe a very good ribbon/planar design will have to deal with this issue

Those are to me the major culprits of any such design

Gap strength is much less an issue

And increased gap strength will only make things worse if the acoustic diffraction problems are ignored

Isnt that exactly where it is at the moment

Last edited:

Ehh, the short one I built was 4feet, which would be like 1.2meter

The big one was like 1.8meter

The big one was difficult to control

It also seemed like it was hanging, due to its higher weight from being longer and wider

If you really want such a big thing I dont see any other way than a planar

That on the other hand might be crossed much lower

An old drawing just to illustrate, I wouldnt do it exactly like that

Not enuff tension tinny ....

No, not if you limit it mechanically

Personally I dont like that

Streching a ribbon is not the best way

All ribbons have certain ressonance problems at their attached ends

When you support a long ribbon in two other places its like having 3 stacked shorter ribbons

And you will have 6x attached ends, instead of 2

Even more ressonance problems, and now closer to listening height

Anyway, I believe its more the width that determines how low it goes

Maybe to some extend also the length, but much less

Well, maybe more realistically both the length and width

But width is a real hurdle to a ribbon

A major issue is still the design with a wide magnet gap, which places the ribbon in a "tunnel"

Consider it like a throath on a compression driver

We cant suddenly ignore the obvious diffraction problems on hand

It may still work ok, but I believe a very good ribbon/planar design will have to deal with this issue

Those are to me the major culprits of any such design

Gap strength is much less an issue

And increased gap strength will only make things worse if the acoustic diffraction problems are ignored

Isnt that exactly where it is at the moment

I do agree that a long narrow ribbon will not have any low freq. vs one with more width less height . Overall total Sq area is what determines this , but anything under 30 mm width will not have any appreciable low end response and of course you sacrifice some of the highs by doing so ...

Stretching the ribbon ( tension ) is the only way to " tune " the ribbon . I have done so with good repeatability , by adding a suspension at each end . You can apply known tension , measure and keep applying tension until desired results are obtained .

Ok, you have your ways around it, I wont argue with that

But in my book, a ribbon is not supposed to move like a woofer

If it does, its used too low

Like any other midrange driver

Simple as that

I never liked tension on a ribbon

A loose ribbon always sounded better to me

It may all work fine at very low SPL

But once you turn it up, problems begin

It needs to be controlled electrically, not mechanically

Just as any other driver

Old story

But in my book, a ribbon is not supposed to move like a woofer

If it does, its used too low

Like any other midrange driver

Simple as that

I never liked tension on a ribbon

A loose ribbon always sounded better to me

It may all work fine at very low SPL

But once you turn it up, problems begin

It needs to be controlled electrically, not mechanically

Just as any other driver

Old story

Last edited:

Tinny ,

How much tension are you using ? a loose ribbon will have to be supported and of course as with all drivers excursion has to be limited to control distortion ..

How much tension are you using ? a loose ribbon will have to be supported and of course as with all drivers excursion has to be limited to control distortion ..

Tinny ,

How much tension are you using ?

Oh, Its about 25years ago, please dont expect me to remember that long back 😉😛

Whatever, I started a small supertweeter ribbon project some years ago

Not finished yet 😱

And after listening to the good man båndseis "fullrange" planars, Im headed in that direction

I want one, simple as that

Ribbons are still as good as ever

They can sound pretty darned sweet

All I say, just dont expect them to be woofers, or to cope with any BSC issues

But I dont think they will ever be any good much below 1khz, which on its own is pretty good fore a ribbon

It means theres little point in making it much wider than 15mm, and happens to be the point where the magnet gap begin to really loose serious strength

And results in the next problem, the higher xo point to the side by side woofer line array

Please dont think Im just being grumpy

I really try to be objective

Last edited:

Hi

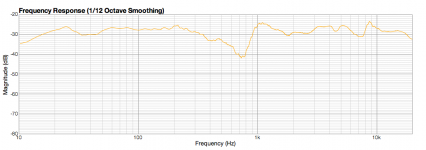

Now I build it with a Gap of 20mm and I have blocks for a gap of 30mm and 50mm that I want to try later.

This design has also major flaws.

There are 2 peaks in the freq range 1 at 1khz that I can't explain and one at 8,5Khz which is the width of the ribbon behind the magnets.

There was no way to get rid off the 1Khz peak.

Only when I closed the back of the ribbon it was gone.

I tried all different kind off baffles to find the problem with no results yet.

I stop with this design because of the 1Khz peak because it's very audible.

Rob

May I remind you, Rob posted this himself, and why we are having this debate

"Grumpy " never crossed my mind ... 😛

Well i did not have the pleasure of hearing Bandshie's Planers , so i would have to accept your Opinion on such 🙂

I have finished my 3 way ribbon and the sound is reasonably good , with mods still left to go . I have incorporated the mods vs diaphragm tension as previously discussed and will admit , diaphragm design and tensions changes the sounds as much as anything else , so i still have a bunch more to play with before it is absolute .

As to Rob, there are design issues that are inherent in his application. It is impossible for a single long/thin ribbon drive to have a full bandwidth, a bass/mid-bass driver would be a must, same as bandshies designs IMO.

It would be interesting to hear the Planer vs Ribbon ( multi-way ), maybe bandshie can post his test results to compare to robs ...

Well i did not have the pleasure of hearing Bandshie's Planers , so i would have to accept your Opinion on such 🙂

I have finished my 3 way ribbon and the sound is reasonably good , with mods still left to go . I have incorporated the mods vs diaphragm tension as previously discussed and will admit , diaphragm design and tensions changes the sounds as much as anything else , so i still have a bunch more to play with before it is absolute .

As to Rob, there are design issues that are inherent in his application. It is impossible for a single long/thin ribbon drive to have a full bandwidth, a bass/mid-bass driver would be a must, same as bandshies designs IMO.

It would be interesting to hear the Planer vs Ribbon ( multi-way ), maybe bandshie can post his test results to compare to robs ...

Last edited:

Well i did not have the pleasure of hearing Bandshie's Planers , so i would have to accept your Opinion on such 🙂

I have finished my 3 way ribbon and the sound is reasonably good , with mods still left to go .

While waiting fore the results from Rob....

Theres nothing like a good ribbon

Lots of ways, and mods that cost next to nothing

Sure, its fun, with certain limitations

But sure, I had "forgot", until I heard bandshies🙂p) planars

With all this new stuff like digtal filters/EQ I feel its due time to pick it up again

And I think I know how to do it

But too early to say

Im looking at some alu tape, but with 0.020mm(20um) maybe a bit heavy

But its marketed as a "soft" tape

But too early to say

Hi,

Good to see another tinker er around!

I am currently building a pair of 72" ribbons for somebody.

I'm making them basically the same way I did in the beginning.

I have upgraded the membrane suspension to support lower x-over points, and am seeking (possibly) a patent on it.

I still don't have femm, and,

\opinion:

I still think it won't improve the sound from strictly a listening standpoint enough to warrant such attention.

I highly doubt a listener could tell the difference in a side-by-side comparison.

/opinion.

Keep up the good work everybody!

paul

Good to see another tinker er around!

I am currently building a pair of 72" ribbons for somebody.

I'm making them basically the same way I did in the beginning.

I have upgraded the membrane suspension to support lower x-over points, and am seeking (possibly) a patent on it.

I still don't have femm, and,

\opinion:

I still think it won't improve the sound from strictly a listening standpoint enough to warrant such attention.

I highly doubt a listener could tell the difference in a side-by-side comparison.

/opinion.

Keep up the good work everybody!

paul

Hi

There's some progress.

I build en new mid high section with a mid 50mm ribbon and high 15mm ribbon

You can see the difference in measurement between the design from valvitude and a ribbon who's the same on front and back.

All measurements are nearfield picture from left to right Valvitude - 50mm Mid - 15mm Tweeter.

Rob

There's some progress.

I build en new mid high section with a mid 50mm ribbon and high 15mm ribbon

You can see the difference in measurement between the design from valvitude and a ribbon who's the same on front and back.

All measurements are nearfield picture from left to right Valvitude - 50mm Mid - 15mm Tweeter.

Rob

Attachments

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- DIY 70" ribbon