Hi

I want to build a 70" ribbon but don't have any experience at all.

Read the topic's from dhenryp and valveitude and read a lot of tips from lineSource.

What would be the best mechanical motor to build with respect to acoustics and flux densety in the gap.

What hapens if you make the diagram wider than 17mm (20Khz)

Which thickness aluminium foil do I need with this project in metric please or what are the compromises.

Mechanical construction is no problem.

I already order 220 Neo N42 magnets from 40x20x10mm.

So I have to start from scratch or just build the same as Valveitude or dhenryp.

I can't find the ribbon from linesource.

Rob

I want to build a 70" ribbon but don't have any experience at all.

Read the topic's from dhenryp and valveitude and read a lot of tips from lineSource.

What would be the best mechanical motor to build with respect to acoustics and flux densety in the gap.

What hapens if you make the diagram wider than 17mm (20Khz)

Which thickness aluminium foil do I need with this project in metric please or what are the compromises.

Mechanical construction is no problem.

I already order 220 Neo N42 magnets from 40x20x10mm.

So I have to start from scratch or just build the same as Valveitude or dhenryp.

I can't find the ribbon from linesource.

Rob

Hello Rob,

The answers to ALL of your questions are in those threads. I realize they are both very long, but the info is there. I highly recommend that you go through them again and copy/paste the important data into a document for easy reference. I would also suggest you download FEMM and start playing with it before you do anything else.

Please understand that the forces involved with the size of Neo magnets you have when you add them together in a frame are tremendous..be careful and have fun.

Casey

Read the topic's from dhenryp and valveitude and read a lot of tips from lineSource.

The answers to ALL of your questions are in those threads. I realize they are both very long, but the info is there. I highly recommend that you go through them again and copy/paste the important data into a document for easy reference. I would also suggest you download FEMM and start playing with it before you do anything else.

Please understand that the forces involved with the size of Neo magnets you have when you add them together in a frame are tremendous..be careful and have fun.

Casey

Hi Valveitude

I downloaded FEMM but have some difficulties to understand how I should draw.

Also don't understand your drawing because it doesn't look like your build.

Can you put your file online so I can see how you did it.

The thickness of the foil you all talk about are always in inches?

And what I read is 0.0005" the thinnest to work with without tearing it apart.

Also see the drawings of the 2 optional motors with or without Iron crossbars but are there other better options.

If you start all over what should you do different.

Rob

I downloaded FEMM but have some difficulties to understand how I should draw.

Also don't understand your drawing because it doesn't look like your build.

Can you put your file online so I can see how you did it.

The thickness of the foil you all talk about are always in inches?

And what I read is 0.0005" the thinnest to work with without tearing it apart.

Also see the drawings of the 2 optional motors with or without Iron crossbars but are there other better options.

If you start all over what should you do different.

Rob

I downloaded FEMM but have some difficulties to understand how I should draw

The built in CAD stinks with FEMM. Use a seperate CAD program and import the DXF file..I use AutoCad but there are plenty o 2D freeware programs available.

Also don't understand your drawing because it doesn't look like your build.

FEMM is a 2D program so you have to dimension the pieces so the cross section is the same as the pieces you are going to use. Review my thread for a more complete explanation.

Can you put your file online so I can see how you did it.

If I can find it. I upgraded my PC since then and am not sure where the files are.

The thickness of the foil you all talk about are always in inches?

Nope...it's in microns.

Casey

Hi

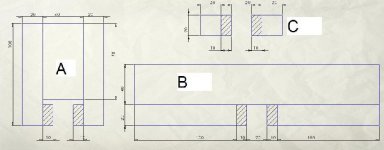

I did some simulations in femm and used the ribbon calc program for spl calculations.

At first I don't trust Femm if you draw the front of the magnet motor but I trust the top view drawings more.

But they are also not perfect.

I think that you have to start somewhere so this is it.

All gaps are 20mm and magnets are 10mm x 20mm N40.

Tesla in the gap from A and B are the same 0.44-0.52T from C its 0.35-0.40T.

Difference between AB and C is about 0.1T

I run the ribbon calc simulation and found out that the difference between 0.375T and 0.480T for a ribbon of 1,8meter long and 20mm wide and 10,5micron thick are about 2dB.

So the difference between A and C in Tesla is about 30% witch yield in only 2dB.

You need to double the Tesla to get 6dB more spl and if you double the ribbon you get 3dB.

For acoustical reason I prefer C and B.

For C front and rear are the same and for B almost except at places where the vertical bar is behind the ribbon.

For construction I also prefer B because of the stiffness of the 100mm wide bar its almost impossible to bend due to the forces of the magnets so the gap difference is less along the length.

I think that I build all 3 at a length of 30cm and do some acoustical measurements and decide which on it will be.

Maybe I can get a gaus meter to measure the tesla in the gap of those 3 examples.

Rob

I did some simulations in femm and used the ribbon calc program for spl calculations.

At first I don't trust Femm if you draw the front of the magnet motor but I trust the top view drawings more.

But they are also not perfect.

I think that you have to start somewhere so this is it.

All gaps are 20mm and magnets are 10mm x 20mm N40.

Tesla in the gap from A and B are the same 0.44-0.52T from C its 0.35-0.40T.

Difference between AB and C is about 0.1T

I run the ribbon calc simulation and found out that the difference between 0.375T and 0.480T for a ribbon of 1,8meter long and 20mm wide and 10,5micron thick are about 2dB.

So the difference between A and C in Tesla is about 30% witch yield in only 2dB.

You need to double the Tesla to get 6dB more spl and if you double the ribbon you get 3dB.

For acoustical reason I prefer C and B.

For C front and rear are the same and for B almost except at places where the vertical bar is behind the ribbon.

For construction I also prefer B because of the stiffness of the 100mm wide bar its almost impossible to bend due to the forces of the magnets so the gap difference is less along the length.

I think that I build all 3 at a length of 30cm and do some acoustical measurements and decide which on it will be.

Maybe I can get a gaus meter to measure the tesla in the gap of those 3 examples.

Rob

Attachments

Hi Casey

Do you now this fore shure?

I think that if you use say 1" wide magnets and a iron bar 4"x1" that you have to draw 4" wide iron in Femm.

If you have 0,5"x4" iron than you have to draw a 2"wide iron in Femm.

So it should be related to the wide of the magnet.

What I read it draws 1mm deep.

Do you now this fore shure?

I think that if you use say 1" wide magnets and a iron bar 4"x1" that you have to draw 4" wide iron in Femm.

If you have 0,5"x4" iron than you have to draw a 2"wide iron in Femm.

So it should be related to the wide of the magnet.

What I read it draws 1mm deep.

valveitude said:

FEMM is a 2D program so you have to dimension the pieces so the cross section is the same as the pieces you are going to use. Review my thread for a more complete explanation.

Casey

Do you now this fore shure?

Pretty sure 😉

You are interested in cross section area. If the real world piece is 1"x4" you have 4 square inches so you would model a 2" wide piece. If you have a piece 1/2" x 4" you have 2 square inches and would model a 1.414" wide piece.

FEMM assumes the depth=width.

This procedure has worked for both myself and dhenryp with very close results with the final product.

Casey

Hi Casey

I'm stubborn so I think you are wrong or maybe I am but please look at my examples.

I do this in millimetres with your ribbon as an example.

You use 100mmx20mm side bars and 10mmx20mm magnets

100x20=2000 correspond with 45mmx45mm

20x10=200 correspond with 14mmx14mm

ratio 1:10 magnets and iron

If I draw this in femm then the iron is over saturated and the strength in the middle of the gap is 0.684

Gap is 15mm wide and 240mm long.

Now if I draw it with a 20mm dept (you can change this in the problem definition).

I draw the magnets 10mm wide and the Iron 100mm the ratio magnet iron are still 1:10

The Iron is not nearly over saturated and the middle of the gap is 0.717

Gap 15mm wide and 240mm long

If you calculate only with cross sections from the iron bar then you change the 1:10 ratio.

So if you are right then I need bigger Iron bars then you did.

If I'm right I can use smaller pieces of iron.😉

I'm on holiday at the moment so I have a lot of time to simulate and think about it maybe to much.😀

When back I try to find someone who know a lot about this subject.

Over here we have a very big magnet supplier and they have the knowledge but I don't now if they want to help.

Rob

I'm stubborn so I think you are wrong or maybe I am but please look at my examples.

I do this in millimetres with your ribbon as an example.

You use 100mmx20mm side bars and 10mmx20mm magnets

100x20=2000 correspond with 45mmx45mm

20x10=200 correspond with 14mmx14mm

ratio 1:10 magnets and iron

If I draw this in femm then the iron is over saturated and the strength in the middle of the gap is 0.684

Gap is 15mm wide and 240mm long.

Now if I draw it with a 20mm dept (you can change this in the problem definition).

I draw the magnets 10mm wide and the Iron 100mm the ratio magnet iron are still 1:10

The Iron is not nearly over saturated and the middle of the gap is 0.717

Gap 15mm wide and 240mm long

If you calculate only with cross sections from the iron bar then you change the 1:10 ratio.

So if you are right then I need bigger Iron bars then you did.

If I'm right I can use smaller pieces of iron.😉

I'm on holiday at the moment so I have a lot of time to simulate and think about it maybe to much.😀

When back I try to find someone who know a lot about this subject.

Over here we have a very big magnet supplier and they have the knowledge but I don't now if they want to help.

Rob

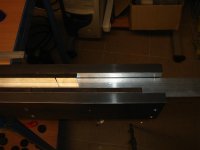

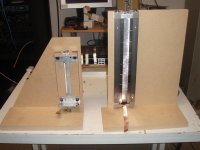

Hi

Inspired by Valvitude i build a ribbon like he did because the well layout magnetic pad from his design.

The ribbon has almost no magnetic radiation and the Iron itself is very little magnetic so the magnetic flux goes only trough the gap.

The sound from it is very good with much attack and resolution.

I also made some extra spacer blocks that are wider.

Now I build it with a Gap of 20mm and I have blocks for a gap of 30mm and 50mm that I want to try later.

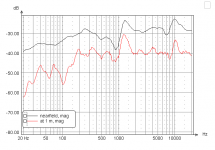

This design has also major flaws.

There are 2 peaks in the freq range 1 at 1khz that I can't explain and one at 8,5Khz which is the width of the ribbon behind the magnets.

Both peaks are very strong and difficult to damp.

So you need 2 notch filters and some damping and then you still have 2 dips at those frequencies.

There was no way to get rid off the 1Khz peak.

Only when I closed the back of the ribbon it was gone.

I tried all different kind off baffles to find the problem with no results yet.

I stop with this design because of the 1Khz peak because it's very audible.

Now I going to build one with the same size but only 20mmx20mm side bars so the front and rear of the ribbon are the same.

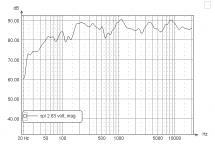

And see what the difference in spl is and sound.

If I find some extra time I post the measurements of the ribbon.

I run the ribbon with a transformer and a 4 Ohm resistor in series with the ribbon only and the resistor sound much better.

What I also want to try is a segmented ribbon and make it about 4 Ohm

Rob

Inspired by Valvitude i build a ribbon like he did because the well layout magnetic pad from his design.

The ribbon has almost no magnetic radiation and the Iron itself is very little magnetic so the magnetic flux goes only trough the gap.

The sound from it is very good with much attack and resolution.

I also made some extra spacer blocks that are wider.

Now I build it with a Gap of 20mm and I have blocks for a gap of 30mm and 50mm that I want to try later.

This design has also major flaws.

There are 2 peaks in the freq range 1 at 1khz that I can't explain and one at 8,5Khz which is the width of the ribbon behind the magnets.

Both peaks are very strong and difficult to damp.

So you need 2 notch filters and some damping and then you still have 2 dips at those frequencies.

There was no way to get rid off the 1Khz peak.

Only when I closed the back of the ribbon it was gone.

I tried all different kind off baffles to find the problem with no results yet.

I stop with this design because of the 1Khz peak because it's very audible.

Now I going to build one with the same size but only 20mmx20mm side bars so the front and rear of the ribbon are the same.

And see what the difference in spl is and sound.

If I find some extra time I post the measurements of the ribbon.

I run the ribbon with a transformer and a 4 Ohm resistor in series with the ribbon only and the resistor sound much better.

What I also want to try is a segmented ribbon and make it about 4 Ohm

Rob

Attachments

Hello Rob,

thanks for the posting the photos , a couple questions ..

1. Does your side plates really need to be that large ?

2. What is the efficiency currently ?

3. Are you still running a trans ?

regards,

thanks for the posting the photos , a couple questions ..

1. Does your side plates really need to be that large ?

2. What is the efficiency currently ?

3. Are you still running a trans ?

regards,

Hi a.wayne

1 No but you have to begin somewhere and I want a woofer line source next to it so this was about the size I needed.

2 With a 3 Ohm series resistor I still have about 86dB spl 2.83 Volt

3 No transformer at the moment.

Rob

1 No but you have to begin somewhere and I want a woofer line source next to it so this was about the size I needed.

2 With a 3 Ohm series resistor I still have about 86dB spl 2.83 Volt

3 No transformer at the moment.

Rob

Hi Rob, nice work

But sounds like the huge iron and resulting "tunnel" behind the ribbon is giving you headackes

Have you tried with some acoustic materials ?

Im working on a much simpler one that only needs one piece of iron, very simple

Its a planar tho

http://www.diyaudio.com/forums/planars-exotics/50162-another-diy-ribbon-thread-55.html

But sounds like the huge iron and resulting "tunnel" behind the ribbon is giving you headackes

Have you tried with some acoustic materials ?

Im working on a much simpler one that only needs one piece of iron, very simple

Its a planar tho

http://www.diyaudio.com/forums/planars-exotics/50162-another-diy-ribbon-thread-55.html

Hi tinitus

Yes that's the problem.

I think I almost try everything with damping inside the back of the ribbon.

My next design is more simple.

Here are some small ribbons that I built and now I am going to build a large one of 200cm.

Rob

Yes that's the problem.

I think I almost try everything with damping inside the back of the ribbon.

My next design is more simple.

Here are some small ribbons that I built and now I am going to build a large one of 200cm.

Rob

Attachments

Rob, its obvious you are very serious about it

I would be cautious with those very long ribbons

They need to be crossed either high, or very steep

In the past I found them to be problematic and preferred a 4feet 15-20mm narrow ribbon, over a 6feet x 25-30mm

Later on, some builders have found that planars work better, fore the very long/high ones

Regarding your 1khz peak

It looks to me like you have problems with dips, rather than peaks

Or maybe they are part of the same problem

I also find the edges/space in front of ribbon to be problematic

Its a common issue

It is possible to to mount the magnets flat on the front

The field will be in line with magnet edges

Thus much less diffraction issues

If you want it more open back, just use smaller pieces of iron with space between them, instead of one long

I would be cautious with those very long ribbons

They need to be crossed either high, or very steep

In the past I found them to be problematic and preferred a 4feet 15-20mm narrow ribbon, over a 6feet x 25-30mm

Later on, some builders have found that planars work better, fore the very long/high ones

Regarding your 1khz peak

It looks to me like you have problems with dips, rather than peaks

Or maybe they are part of the same problem

I also find the edges/space in front of ribbon to be problematic

Its a common issue

It is possible to to mount the magnets flat on the front

The field will be in line with magnet edges

Thus much less diffraction issues

If you want it more open back, just use smaller pieces of iron with space between them, instead of one long

Last edited:

Hi a.wayne

If I calculate the voltage acros the ribbon with 3 Ohm in series and the ribbon is about 0,2 Ohm its 0.18 volt.

If you have 0,44 volt at 0,2 Ohm is about 1W.

So 0,44/0.18=2.44=7,8dB.

Now with the 3 Ohm resistor I have 86dB

So the sensitivity will be 94dB at 1W.

Rob

If I calculate the voltage acros the ribbon with 3 Ohm in series and the ribbon is about 0,2 Ohm its 0.18 volt.

If you have 0,44 volt at 0,2 Ohm is about 1W.

So 0,44/0.18=2.44=7,8dB.

Now with the 3 Ohm resistor I have 86dB

So the sensitivity will be 94dB at 1W.

Rob

Hi tinitus

The dips and peaks are part of the same problem.

Can you explain that why the smaller ribbon is better?

I want to make a large one because I want a good line source and they should almost fit between the floor and ceiling.

I hate the short ribbons from about 50cm because the bad vertical dispersion.

Maybe that was your problem in comparing the 2 ribbons you build.

Rob

The dips and peaks are part of the same problem.

Can you explain that why the smaller ribbon is better?

I want to make a large one because I want a good line source and they should almost fit between the floor and ceiling.

I hate the short ribbons from about 50cm because the bad vertical dispersion.

Maybe that was your problem in comparing the 2 ribbons you build.

Rob

"There are 2 peaks in the freq range 1 at 1khz that I can't explain and one at 8,5Khz which is the width of the ribbon behind the magnets.

Both peaks are very strong and difficult to damp."

That is why I spent so much time layering up my felt dampening in a way that eliminated parallel surfaces behind the ribbon. 😀

Awesome job by the way.

Casey

Both peaks are very strong and difficult to damp."

That is why I spent so much time layering up my felt dampening in a way that eliminated parallel surfaces behind the ribbon. 😀

Awesome job by the way.

Casey

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- DIY 70" ribbon