Hi everyone.

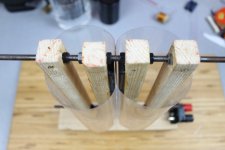

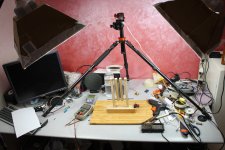

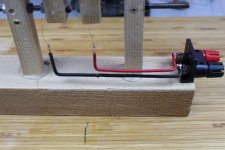

I present to you today a somewhat bizarre project, it is a ribbon speaker inspired from an old tweeter used by the linaeum company in two-way speakers.

In my model I changed the size of the ribbon and its material, I tried several materials before deciding to use plastic as ribbon because it sounds better than other types of paper.

The project is very simple and easy to do, the correct name of this speaker is Rubanoide speaker.

the speaker has no cabinet but it can plays the sound loud down to 150hz very well like a a small full range speaker, the reproduction of midrange is really very impressive and clear.

you will find attached the photos of the project as well as the link of the video which shows all the stages of manufacture in my youtube channel where you will find other audio projects.

you welcome

I present to you today a somewhat bizarre project, it is a ribbon speaker inspired from an old tweeter used by the linaeum company in two-way speakers.

In my model I changed the size of the ribbon and its material, I tried several materials before deciding to use plastic as ribbon because it sounds better than other types of paper.

The project is very simple and easy to do, the correct name of this speaker is Rubanoide speaker.

the speaker has no cabinet but it can plays the sound loud down to 150hz very well like a a small full range speaker, the reproduction of midrange is really very impressive and clear.

you will find attached the photos of the project as well as the link of the video which shows all the stages of manufacture in my youtube channel where you will find other audio projects.

you welcome

Attachments

-

IMG_3434.JPG184.7 KB · Views: 1,056

IMG_3434.JPG184.7 KB · Views: 1,056 -

IMG_3437.JPG505.5 KB · Views: 756

IMG_3437.JPG505.5 KB · Views: 756 -

IMG_3438.JPG397 KB · Views: 758

IMG_3438.JPG397 KB · Views: 758 -

IMG_3442.JPG334.2 KB · Views: 1,106

IMG_3442.JPG334.2 KB · Views: 1,106 -

IMG_3443.JPG380.8 KB · Views: 736

IMG_3443.JPG380.8 KB · Views: 736 -

IMG_3444.JPG197.9 KB · Views: 1,301

IMG_3444.JPG197.9 KB · Views: 1,301 -

IMG_3462.JPG200.9 KB · Views: 773

IMG_3462.JPG200.9 KB · Views: 773 -

IMG_3465.JPG170.1 KB · Views: 723

IMG_3465.JPG170.1 KB · Views: 723 -

IMG_3471.JPG248.3 KB · Views: 727

IMG_3471.JPG248.3 KB · Views: 727 -

IMG_3475.JPG355 KB · Views: 711

IMG_3475.JPG355 KB · Views: 711 -

IMG_3478.JPG236.7 KB · Views: 777

IMG_3478.JPG236.7 KB · Views: 777

Hello Steve great video did you take the measurements? 150 Hz is very low for such a small rubanoid? Where is the plastic membrane from? How thick is it and what is its weight per square meter? Greetings

I stumbled on to this video on youtube. It looks great. Did you ever take any measurements or make any refinements to the design?

I’ve been pondering this design all day 🤔 (These are hypothetical questions, not directed at you OP.) What would happen if it was lengthened to say 6 feet tall? I guess it could be a full range tower. What if it was widened to two feet wide and made of thicker material? Could it be a dipole subwoofer or would it be more efficient? What if you used the 2’ wide on the bottom, an eight inch, then a three inch, then a one inch for a four way? What if neodymium magnets were used for higher flux density? Should there be damping (wool) on the inside, or on the outside edges? What are the effects of a wider design, heavier material, stiffer material. You said paper was unsatisfactory, I’m wondering why? Can you imagine towers of beryllium? O.O Does the shape of the radiation surface matter? Does it have to be cardioid or two cylinders? Does a baffle help or hurt?

I am novice in this field and need some help here, I just followed your instructions and created these with similar materials like 32guage copper wire approx. 35 rounds on a cd case, 200 microns acetate sheet etc which were available at my home. But the sound I am getting is too low (really hard to hear). Please help in troubleshooting the problem. Thanks in advance.

@peril

please write in English.

I've translate your message here below:

please write in English.

I've translate your message here below:

"hello ankit....

Hello, maybe this is your problem? the magnetization must change due to the direction of the electronic current.

Greetings"

I agree with Peril, you may have a magnet phase problem. Those little buggers are always flipping over and spinning around.I am novice in this field and need some help here, I just followed your instructions and created these with similar materials like 32guage copper wire approx. 35 rounds on a cd case, 200 microns acetate sheet etc which were available at my home. But the sound I am getting is too low (really hard to hear). Please help in troubleshooting the problem. Thanks in advance.

Other than that I would guess you have a short in the winding. Use a meter to check the windings.

I know it's been a while, but did you ever try to make a 6' version?I’ve been pondering this design all day 🤔 (These are hypothetical questions, not directed at you OP.) What would happen if it was lengthened to say 6 feet tall? I guess it could be a full range tower. What if it was widened to two feet wide and made of thicker material? Could it be a dipole subwoofer or would it be more efficient? What if you used the 2’ wide on the bottom, an eight inch, then a three inch, then a one inch for a four way? What if neodymium magnets were used for higher flux density? Should there be damping (wool) on the inside, or on the outside edges? What are the effects of a wider design, heavier material, stiffer material. You said paper was unsatisfactory, I’m wondering why? Can you imagine towers of beryllium? O.O Does the shape of the radiation surface matter? Does it have to be cardioid or two cylinders? Does a baffle help or hurt?

My biggest concern would be that it would sag in the middle as its held up on the outside.

No I haven’t, sorry. I’ve been working on a traditional looking wtw where the woofers don’t come alive until I pump some power into them. Good for a pro sound setup, I guess. Anyway …

Thanks for the reminder! I haven’t forgotten about it, I’m just doing other things. I don’t think sagging will be an issue with a longer diaphragm because the force should be the same per length of the radiator. Larger, heavier diameters will sag, so there is a limit to how big the diaphragm radius can be. Of course that depends on the materials used. I’m not sure how I will get the voice coils made. I’ll obviously have to make a jig or maybe run smaller ones parallel and series? I need a source for magnets, lots of magnets. Thanks, man, you got me thinking and thinking is good!

Thanks for the reminder! I haven’t forgotten about it, I’m just doing other things. I don’t think sagging will be an issue with a longer diaphragm because the force should be the same per length of the radiator. Larger, heavier diameters will sag, so there is a limit to how big the diaphragm radius can be. Of course that depends on the materials used. I’m not sure how I will get the voice coils made. I’ll obviously have to make a jig or maybe run smaller ones parallel and series? I need a source for magnets, lots of magnets. Thanks, man, you got me thinking and thinking is good!

- Home

- Loudspeakers

- Full Range

- Diy 360° Full range Rubanoide Speaker