What is the best solvent for epoxy that won't harm PCB's?

Application is automotive; an ABS computer. The PCB is SMT with thin traces, looks multilayered and looks relatively fragile. Epoxy is used quite copiously, seems to be solely for waterproofing and not for IP protection.

It looks like the answer is to soak the whole assembly in something strong that will not attack the PCB or circuit components.

Anybody?

Application is automotive; an ABS computer. The PCB is SMT with thin traces, looks multilayered and looks relatively fragile. Epoxy is used quite copiously, seems to be solely for waterproofing and not for IP protection.

It looks like the answer is to soak the whole assembly in something strong that will not attack the PCB or circuit components.

Anybody?

Heat with a heat gun to soften and scrape the epoxy off with a plastic spudger. I've done this throughout my >30yr career in electronics with a very high success rate.

Thanks for the tip. I'm not 100% sure that's possible since I don't have one in hand yet and one side of the PCB may be fully covered (i.e. as if it was epoxied to the bottom of a box without removable bottom).

Epoxy and PCB are both made out of epoxy, so you can´t dissolve one and not the other.What is the best solvent for epoxy that won't harm PCB's?

....................................

It looks like the answer is to soak the whole assembly in something strong that will not attack the PCB or circuit components.

That besides the point that epoxy is not soluble on anything you can handle.

This guy etches away IC Epoxy (not the same as "dissolving") for a similar purpose but it is NASTY

Posted only as information:

Decapping ICs (removing epoxy packaging from chips to expose the dies) - YouTube

IF pulling it away in large chunks is enough, a hot air gun (not a hair dryer) and a dental pick can help you, but it´s a blunt/rough tool.

EASY to destroy what you are trying to investigate.

I was looking for something to do this about 20 years ago and just found realy nasty chemicals that were hard to get. So I tried again and found this.

Attack Epoxy Solvent | Gesswein

Be sure to read the SDS, " Harmful if inhaled, Maybe harmful if swallowed"

Attack Epoxy Solvent | Gesswein

I guess that nobody has managed to swallow it

Reviews

Amazon.com: Customer reviews: Attack Solvent Epoxy Resin Glue Remover GLU-250.00

..

Oh, sorry. cannot ship outside of the USA.

Canada link

Attack Epoxy Solvent

Attack Epoxy Solvent | Gesswein

Be sure to read the SDS, " Harmful if inhaled, Maybe harmful if swallowed"

Attack Epoxy Solvent | Gesswein

I guess that nobody has managed to swallow it

Reviews

Amazon.com: Customer reviews: Attack Solvent Epoxy Resin Glue Remover GLU-250.00

..

Oh, sorry. cannot ship outside of the USA.

Canada link

Attack Epoxy Solvent

Last edited:

It really depends on the chemistries at play, sadly. Especially as there are "epoxies" that are only in name, having no polyepoxide bonds.

So this isn't *quite* as diverse a question as "how to dissolve plastic", but not far off sadly.

Plus it's not fun breaking down anything good and crosslinked. :/

So this isn't *quite* as diverse a question as "how to dissolve plastic", but not far off sadly.

Plus it's not fun breaking down anything good and crosslinked. :/

Last edited:

Fuming Nitric acid. Very nasty stuff. One should only use it under a fume hood. Even then, great care must be exercised. It is, AFAIK, the preferred way to remove the plastic packaging of integrated circuits and transistors in order to expose the Silicon die beneath (for failure analysis and such).

If I were you I would see how far you can get with heat and scraping. Failing that, buy a new ABS unit ;-)

If I were you I would see how far you can get with heat and scraping. Failing that, buy a new ABS unit ;-)

If you find a solvent for epoxy, it will probably dissolve or damage the components on the PCB (e.g. capacitors, electrolytics). Transistors and IC-s are also protected by epoxy.

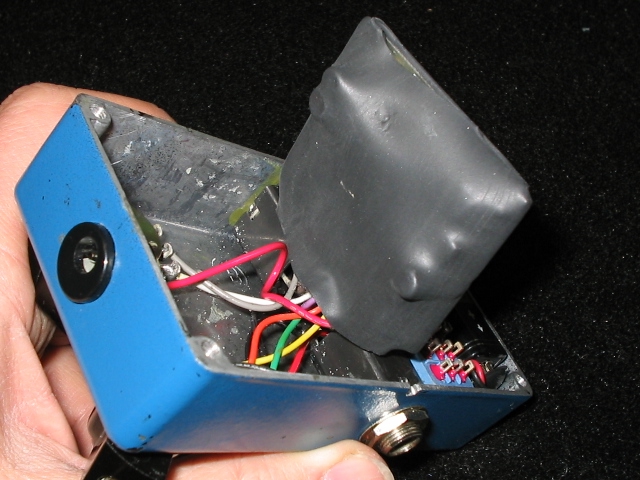

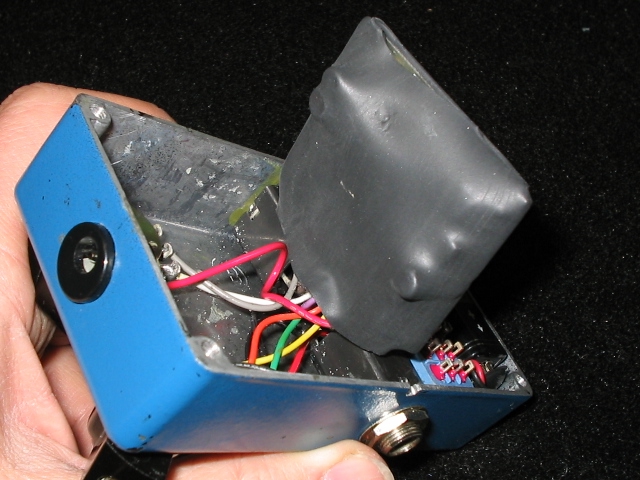

DIY pedal builders run against this all the time, since practically all boutique pedals are "gooped" .

This might help you:

Goop Removal Theory Topic

Some examples:

Klon Centaur pedal:

Diaz pedal:

Notice ugly/sad state of degooped PCB 😱

It was previously X-Rayed 😱

Funny thing, it even shows IC guts.

I find it crazy to goop parts such as multiturn trimmer resistors, what were they thinking?

This might help you:

Goop Removal Theory Topic

Some examples:

Klon Centaur pedal:

Diaz pedal:

Notice ugly/sad state of degooped PCB 😱

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

It was previously X-Rayed 😱

An externally hosted image should be here but it was not working when we last tested it.

Funny thing, it even shows IC guts.

I find it crazy to goop parts such as multiturn trimmer resistors, what were they thinking?

Last edited:

Fuming Nitric acid. Very nasty stuff. One should only use it under a fume hood. Even then, great care must be exercised. It is, AFAIK, the preferred way to remove the plastic packaging of integrated circuits and transistors in order to expose the Silicon die beneath

A main advantage of this technique is that a passivated IC will typically still be functional. I posted a picture of a genuine 2SK170 that we did in the lab years ago.

The classic first step to dissolving epoxy potting is using glacial acetic acid. Nasty, stinky, irritating stuff, but still loads better than RFNA. RFNA is reserved for the more exotic potting epoxies used in transistor and IC packaging, especially the high temperature, high voltage variety. I once had to trace out some circuits in a potted module that had been depotted - all the transistors were either TO-105 or TO-106 (ceramic base with epoxy top), and the depotting solvent dissolved the tops off the transistors, leaving the ceramic base, chip, and bonding wires. Good luck telling what part number and sex...

Heat with a heat gun to soften and scrape the epoxy off with a plastic spudger. I've done this throughout my >30yr career in electronics with a very high success rate.

+1 for the hot air gun tip plus that magic ingredient called patience. See this thread for inspiration... Metaxas CP-1 - Impossible repair? Crackling & Popping on one channel.

isopropyl alcohol, denatured alcohol, or paint thinner can be used depending on the hardness of the epoxy. After loosening the poxy, use a scraper tool and gently pry the epoxy from the surface

I recently de-epoxied a 30yo marine engine 'black box' using a heat gun, podger and patience.

The PCB was epoxied to the bottom of the potting case but released fully intact and with a very satisfying noise.

I managed to get the whole thing uncovered in about half hour with little damage.

The PCB was epoxied to the bottom of the potting case but released fully intact and with a very satisfying noise.

I managed to get the whole thing uncovered in about half hour with little damage.

These potting compounds being described are *not* the same as epoxies. The folks talking about burning away the epoxy with nitric are on the right track, epoxide bonds are very tough to crack.

https://www.tedpella.com/technote_html/Reworking_Cured_Epoxy.pdf

That said, the OP might have a part potted in a form of lacquer, which would be soluble (eventually) in some of these solvents being listed.

https://www.tedpella.com/technote_html/Reworking_Cured_Epoxy.pdf

That said, the OP might have a part potted in a form of lacquer, which would be soluble (eventually) in some of these solvents being listed.

- Home

- General Interest

- Everything Else

- Dissolving epoxy?