Hello everyone,

I was looking around at different driver designs for an SE 300b, when I came across a post on the JAC music website (EML tube distributor) stating that one big source of output tube failure was the use of direct coupling between the driver and output.

Jac, who wrote the post, gave no further explanation.

Does anybody have experience with this who might be able to outline the risks?

I have recently changed my voltage-amp/driver stage to one that does direct couple the output tube. This is based an a schematic that Wavebourn pointed to a while back.

Great sounding circuit. More power and less distortion than others I have tried.

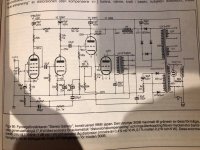

(See below for schematic, if you are curious.)

Thanks in advance for your advice!

Regards,

John

View attachment 880983

I was looking around at different driver designs for an SE 300b, when I came across a post on the JAC music website (EML tube distributor) stating that one big source of output tube failure was the use of direct coupling between the driver and output.

Jac, who wrote the post, gave no further explanation.

Does anybody have experience with this who might be able to outline the risks?

I have recently changed my voltage-amp/driver stage to one that does direct couple the output tube. This is based an a schematic that Wavebourn pointed to a while back.

Great sounding circuit. More power and less distortion than others I have tried.

(See below for schematic, if you are curious.)

Thanks in advance for your advice!

Regards,

John

View attachment 880983

Sorry about that. I’m posting from my phone. Something must have gone wrong.

Hopefully the above attachment works.

Thanks for your reply!

Hopefully the above attachment works.

Thanks for your reply!

Hi Astouffer,

Thanks for your reply.

Do you mean this particular schematic shows the wrong voltage on the grid?

Or do you mean, in general, one may incur a situation in which the grid sees the wrong voltage and thus bias current drifts out of range?

Thanks!

Regards,

John

Thanks for your reply.

Do you mean this particular schematic shows the wrong voltage on the grid?

Or do you mean, in general, one may incur a situation in which the grid sees the wrong voltage and thus bias current drifts out of range?

Thanks!

Regards,

John

The 300B warms up first.

The 12BH7 warms up later.

It is not likely to happen, but . . .

If the first half of the 12BH7 fails open;

Or if the first half of the 12BH7 warms up later than the second half of the 12BH7;

Or if the 12BH7 cathode follower resistor overheats and opens up;

Or if the -200V bias fails;

Or any other failure that causes quiescent 300B grid current;

Then there will be lots of positive voltage on the grid of the 300B, resulting in lots of plate current.

One question to ask yourself is whether you want to run the 300B into A2 operation (drawing grid current).

This circuit will do that.

If you only want the 300B to run in A1 operation (no grid current),

Then a 1A 1000V rectifier diode anode at the 300B grid, and the diode cathode at the center point of the 300B filament supply will work to prevent any significant 300B grid current.

It can pass all the current that the 12BH7 cathode can deliver, and shunt it to the 300B filament circuit.

A fast 1000V 1A diode will not have significant capacitance versus the 12BH7's cathode impedance, so the high frequency response will not be affected.

The 12BH7 warms up later.

It is not likely to happen, but . . .

If the first half of the 12BH7 fails open;

Or if the first half of the 12BH7 warms up later than the second half of the 12BH7;

Or if the 12BH7 cathode follower resistor overheats and opens up;

Or if the -200V bias fails;

Or any other failure that causes quiescent 300B grid current;

Then there will be lots of positive voltage on the grid of the 300B, resulting in lots of plate current.

One question to ask yourself is whether you want to run the 300B into A2 operation (drawing grid current).

This circuit will do that.

If you only want the 300B to run in A1 operation (no grid current),

Then a 1A 1000V rectifier diode anode at the 300B grid, and the diode cathode at the center point of the 300B filament supply will work to prevent any significant 300B grid current.

It can pass all the current that the 12BH7 cathode can deliver, and shunt it to the 300B filament circuit.

A fast 1000V 1A diode will not have significant capacitance versus the 12BH7's cathode impedance, so the high frequency response will not be affected.

Last edited:

Hi Astouffer,

Thanks for your reply.

Do you mean this particular schematic shows the wrong voltage on the grid?

Or do you mean, in general, one may incur a situation in which the grid sees the wrong voltage and thus bias current drifts out of range?

Thanks!

Regards,

John

The schematic is probably correct but like 6A3sUMMER says in the unlikely event of something failing the 300b could be damaged as a result.

Hey! Thanks for the replies!

So, is it only if something fails that problems will arise?

The way I have built the amps, I switch on the 300b filament supply and bias voltage first—before B+ or 6.3V heaters are powered up.

A2– I think I like the A2 operation mode. These amps with the above driver set-up work quite well with ~88db sensitive speakers.

I appreciate the grid->cathode diode tip, though. I will store that in my notes.

Regards,

John

So, is it only if something fails that problems will arise?

The way I have built the amps, I switch on the 300b filament supply and bias voltage first—before B+ or 6.3V heaters are powered up.

A2– I think I like the A2 operation mode. These amps with the above driver set-up work quite well with ~88db sensitive speakers.

I appreciate the grid->cathode diode tip, though. I will store that in my notes.

Regards,

John

That certainly looks like a nice design to try out. You could fuse the output stage with a 250mA fuse to give yourself some added protection, but you'd have to have a pretty catastrophic tube failure to run into problems with that.

Hi Audiowize,

Yes, a fuse is probably a good idea. I had thought about installing one on the B+ at the OPT primary. Next time I have the amps on the bench, I will do that.

Regards,

John

Yes, a fuse is probably a good idea. I had thought about installing one on the B+ at the OPT primary. Next time I have the amps on the bench, I will do that.

Regards,

John

The 300B warms up first.

The 12BH7 warms up later.

Hi 6A3sUMMER,

Thanks for you post!

Your first statement, quoted above, is that just a run down of the typical scenario? Or are you suggesting that if the 300b warms up before the 12bh7 problems may occur?

Sorry if that is a stupid question.

Thanks again for your help.

Regards,

John

Depending on how the filaments are powered, 300B tubes warm up fast.

A simple AC powered 300B filament starts drawing plate current almost immediately.

If they have a soft-start filament supply, then they will warm up slowly.

I used to use a brute force DC filament supply, 6.3VAC, Schottky Bridge, 20,000uf first cap, a series 2 Ohm power resistor, and 20,000uF second cap. The 5V 300B filament warmed up slowly, because of the series 2 Ohm resistor. A hot 300B filament is 4 Ohms (5V/1.25A).

But cold, the 300B filament is far less resistance (perhaps 1 to 2 Ohms). The 2 Ohm resistor limits the current for when the 300B filament is cold, and limits the voltage to 5V when the 300B filament is hot. The limited start up current cases the 300B filament to warm up slowly.

A 12BH7 has two filaments, and 2 cathodes. The filaments have to warm up first, before the cathodes become warm.

The 2 halves of a 12BH7 will most likely warm up at the same time.

Normal operation of your schematic will prevent the 12BH7 from driving grid current into the 300B at power-up.

Whenever you are using a fuse in the output stage, then if the fuse opens, the B+ voltage of all the filter caps may rise to the maximum voltage.

Be sure to use voltage ratings on all the caps that will take the voltage of the unloaded B+.

If the first filter cap has to have a 550V rating, then all the filter caps should have a 550V rating (or else the other tubes will have to draw enough current to keep the downstream capacitors at a lower voltage (voltage drop through the resistors of a CRCRC filter).

Using solid state rectifiers, and cap input B+ filter, the B+ is 1.414 times the rms of the secondary for a bridge.

In your schematic, there is a solid state bridge from 370VAC. That is 523V peak, unloaded, the B+ will be 523VDC.

The first cap is rated at 550V. The problem is that all the downstream caps are only rated at 450V.

Any time the tubes are not conducting, the 450V caps are over their voltage rating.

Your schematic shows AC powerd 300B filaments. Is that what you have?

Are your hum levels low enough?

A simple AC powered 300B filament starts drawing plate current almost immediately.

If they have a soft-start filament supply, then they will warm up slowly.

I used to use a brute force DC filament supply, 6.3VAC, Schottky Bridge, 20,000uf first cap, a series 2 Ohm power resistor, and 20,000uF second cap. The 5V 300B filament warmed up slowly, because of the series 2 Ohm resistor. A hot 300B filament is 4 Ohms (5V/1.25A).

But cold, the 300B filament is far less resistance (perhaps 1 to 2 Ohms). The 2 Ohm resistor limits the current for when the 300B filament is cold, and limits the voltage to 5V when the 300B filament is hot. The limited start up current cases the 300B filament to warm up slowly.

A 12BH7 has two filaments, and 2 cathodes. The filaments have to warm up first, before the cathodes become warm.

The 2 halves of a 12BH7 will most likely warm up at the same time.

Normal operation of your schematic will prevent the 12BH7 from driving grid current into the 300B at power-up.

Whenever you are using a fuse in the output stage, then if the fuse opens, the B+ voltage of all the filter caps may rise to the maximum voltage.

Be sure to use voltage ratings on all the caps that will take the voltage of the unloaded B+.

If the first filter cap has to have a 550V rating, then all the filter caps should have a 550V rating (or else the other tubes will have to draw enough current to keep the downstream capacitors at a lower voltage (voltage drop through the resistors of a CRCRC filter).

Using solid state rectifiers, and cap input B+ filter, the B+ is 1.414 times the rms of the secondary for a bridge.

In your schematic, there is a solid state bridge from 370VAC. That is 523V peak, unloaded, the B+ will be 523VDC.

The first cap is rated at 550V. The problem is that all the downstream caps are only rated at 450V.

Any time the tubes are not conducting, the 450V caps are over their voltage rating.

Your schematic shows AC powerd 300B filaments. Is that what you have?

Are your hum levels low enough?

Last edited:

A DC-coupled cathode-follower, like that used in the example schematic is probably fairly safe.

But I think Jac is referring to the kind of DC-coupled circuits that use indirectly-heated drivers whose anode is dc-coupled to the directly-heated triode end-stage.

In this case the DHT's grid is fed a large positive voltage, if all power supplies come up together (not unusual in recent commercial amps, with one PT and solid-state rectifiers).

EML tubes are very well-made - better than other modern DHTs. But with that comes high cost; this means that taking risks with the circuit could lead to expensive failures.

DC coupling - along with IT-coupling - does have the great advantage of eliminating 'blocking distortion' though; and this is a real problem for 300B-SE amps in practice.

[blocking distortion: When peak signal to the 300B makes the grid go positive, the grid draws current though the grid cap, and builds charge on the cap. This charge then biases the 300B colder, an affects the sound]

BTW, one would not use a cathode follower to dc-couple the grid, nowadays IMHO. Recent power-FETs have lower effective input capacitance, and stable performance. But FETs fail short-circuit, if their Vgs, Vds or SOA is violated, even for a moment, so some kind of circuit protection is still required.

But I think Jac is referring to the kind of DC-coupled circuits that use indirectly-heated drivers whose anode is dc-coupled to the directly-heated triode end-stage.

In this case the DHT's grid is fed a large positive voltage, if all power supplies come up together (not unusual in recent commercial amps, with one PT and solid-state rectifiers).

EML tubes are very well-made - better than other modern DHTs. But with that comes high cost; this means that taking risks with the circuit could lead to expensive failures.

DC coupling - along with IT-coupling - does have the great advantage of eliminating 'blocking distortion' though; and this is a real problem for 300B-SE amps in practice.

[blocking distortion: When peak signal to the 300B makes the grid go positive, the grid draws current though the grid cap, and builds charge on the cap. This charge then biases the 300B colder, an affects the sound]

BTW, one would not use a cathode follower to dc-couple the grid, nowadays IMHO. Recent power-FETs have lower effective input capacitance, and stable performance. But FETs fail short-circuit, if their Vgs, Vds or SOA is violated, even for a moment, so some kind of circuit protection is still required.

For a Class A single ended 300B, there is class A1 or class A2:

Suppose for example, the grid is at 0V, and the filament is biased at +75V

(Quiescent state).

The grid is 75V more negative than the filament (75V bias).

Then, for Class A1, with +75V peak grid signal, the plate draws its peak current.

But, the signal is also going to go the other direction to -75V peak grid signal. And that will turn the 300B off (grid at -150V versus the filament voltage). That is clipping.

Even if there is a very small plate current there, the plate resistance, rp, is so much higher than the quiescent plate's rp of 700 Ohms. Then, with the grid signal at -75V, the 300B grid is at or near cutoff, the plate has no control over the output transformer and no control over the loudspeaker.

Now, turn up the volume to draw grid current and go into A2 operation.

We could use +80V of grid signal, draw grid current, but then the 300B would be cut off when the signal became -80V. 75V bias and -80V = -155V grid to filament. Severe clipping for part of the signal time.

Now, for example, lets use a bias of 85V (grid at 0V and filament at +85V, quiescent)

Then, for Class A2, with +90V peak grid signal, the plate draws its peak current.

The grid is +5V more than the filament voltage, and we draw grid current.

But, the signal is also going to go the other direction to -90V peak grid signal. And that will turn the 300B off (grid at -175V versus the filament voltage). The plate has absolutely no control over the output transformer and no control over the loudspeaker.

You can adjust the bias, and the grid signal, but at some point, if the signal voltage is large enough, the amp will go into cutoff (clipping).

My favorite saying about clipping is:

If the amp is clipping, either turn the volume down,

Or get a more powerful amplifier.

(or use the amp as a Rock Guitar Amplifier)

Suppose for example, the grid is at 0V, and the filament is biased at +75V

(Quiescent state).

The grid is 75V more negative than the filament (75V bias).

Then, for Class A1, with +75V peak grid signal, the plate draws its peak current.

But, the signal is also going to go the other direction to -75V peak grid signal. And that will turn the 300B off (grid at -150V versus the filament voltage). That is clipping.

Even if there is a very small plate current there, the plate resistance, rp, is so much higher than the quiescent plate's rp of 700 Ohms. Then, with the grid signal at -75V, the 300B grid is at or near cutoff, the plate has no control over the output transformer and no control over the loudspeaker.

Now, turn up the volume to draw grid current and go into A2 operation.

We could use +80V of grid signal, draw grid current, but then the 300B would be cut off when the signal became -80V. 75V bias and -80V = -155V grid to filament. Severe clipping for part of the signal time.

Now, for example, lets use a bias of 85V (grid at 0V and filament at +85V, quiescent)

Then, for Class A2, with +90V peak grid signal, the plate draws its peak current.

The grid is +5V more than the filament voltage, and we draw grid current.

But, the signal is also going to go the other direction to -90V peak grid signal. And that will turn the 300B off (grid at -175V versus the filament voltage). The plate has absolutely no control over the output transformer and no control over the loudspeaker.

You can adjust the bias, and the grid signal, but at some point, if the signal voltage is large enough, the amp will go into cutoff (clipping).

My favorite saying about clipping is:

If the amp is clipping, either turn the volume down,

Or get a more powerful amplifier.

(or use the amp as a Rock Guitar Amplifier)

Last edited:

Hi 6A3sUMMER, Hi Rod Colman,

Thanks, as always for your replies!

Rod: Okay, good to know. That is the sort of clarification I was looking for.

As you know, I am thinking about trying a FET/MOSFET-based driver. There are your new Source Follower boards coming up, and I also have all the parts to try Tubelab's PowerDrive circuit.

But for the time being, this cathode follower circuit sounds very nice. These are the first SE amps I have had at home that I have really enjoyed and, in real terms (um, ehem, subjectively I mean) they have outdone my push-pull amps in important areas.

6A3sUMMER: I am using a DC filament supply. Currently a pair of Rod Coleman's filament regulators.

I did try the 300b with AC filaments at first and had only very tiny amounts of hum. That was with a John Broksie Akido-style Driver circuit, though, so there may have been some slight hum cancellation going on.

DC filaments, ultimately, sound better to my ear.

Thanks for the A1/A2 explanation. Very helpful.

I have read a bit, here and there about the advantages and disadvantages of A2 operation. That is how I happened to build this particular circuit--also because I happened to have most of the parts already.

A2 was something I specifically was aiming for here. Especially after trying a couple of other drivers with the 88db speakers, I was very curious to see if it would make a difference.

So far I really like it. Subjectively, it is capable of playing much louder with much lower distortion, and clips (at least audibly) at much higher output level.

I don't own a scope, so I cannot confirm this empirically. Sorry. I know I really need to be able to scope my projects before commenting on them. Some kind of O-scope is in the plans for the nearish future.

Best regards,

John

Thanks, as always for your replies!

Rod: Okay, good to know. That is the sort of clarification I was looking for.

As you know, I am thinking about trying a FET/MOSFET-based driver. There are your new Source Follower boards coming up, and I also have all the parts to try Tubelab's PowerDrive circuit.

But for the time being, this cathode follower circuit sounds very nice. These are the first SE amps I have had at home that I have really enjoyed and, in real terms (um, ehem, subjectively I mean) they have outdone my push-pull amps in important areas.

6A3sUMMER: I am using a DC filament supply. Currently a pair of Rod Coleman's filament regulators.

I did try the 300b with AC filaments at first and had only very tiny amounts of hum. That was with a John Broksie Akido-style Driver circuit, though, so there may have been some slight hum cancellation going on.

DC filaments, ultimately, sound better to my ear.

Thanks for the A1/A2 explanation. Very helpful.

I have read a bit, here and there about the advantages and disadvantages of A2 operation. That is how I happened to build this particular circuit--also because I happened to have most of the parts already.

A2 was something I specifically was aiming for here. Especially after trying a couple of other drivers with the 88db speakers, I was very curious to see if it would make a difference.

So far I really like it. Subjectively, it is capable of playing much louder with much lower distortion, and clips (at least audibly) at much higher output level.

I don't own a scope, so I cannot confirm this empirically. Sorry. I know I really need to be able to scope my projects before commenting on them. Some kind of O-scope is in the plans for the nearish future.

Best regards,

John

Elsewhere on this forum Rod posted a 300B B+ supply using a cap multiplier.

The cap multiplier can have the components sized to give a slow ramp up of the HV.

It's worth looking up.

t

The cap multiplier can have the components sized to give a slow ramp up of the HV.

It's worth looking up.

t

hi 6A3Summer,

>If the amp is clipping, either turn the volume down,

> Or get a more powerful amplifier.

I thought exactly the same way, when I built a 300B-SE for the first time.

But now I find that with a better-designed driver stage - one that does not cause its power supply to sag when clipped, and recovers instantly from overload, I can clip the amp quite deeply without it being clearly audible.

Of course there are all kinds of caveats about such a claim, and can quite accept anyone thinking differently.

With my copies of Lynn's speaker, it is loud at clipping volumes, and distortion of the ear and that of the amp are harder to distinguish. I mostly listen to orchestral & chamber music, where large, but brief peaks come along among low average levels, and I find distortion in general more intrusive at lower levels.

And if we play LPs, surface defects can clip otherwise well-behaved music.

But the overall effect is very different between DC-coupled (fixed bias) versions - compared to RC-coupled grid-drive. Blocking distortion makes for cold and feeble sound, and I find it well worth the trouble of eliminating it.

>If the amp is clipping, either turn the volume down,

> Or get a more powerful amplifier.

I thought exactly the same way, when I built a 300B-SE for the first time.

But now I find that with a better-designed driver stage - one that does not cause its power supply to sag when clipped, and recovers instantly from overload, I can clip the amp quite deeply without it being clearly audible.

Of course there are all kinds of caveats about such a claim, and can quite accept anyone thinking differently.

With my copies of Lynn's speaker, it is loud at clipping volumes, and distortion of the ear and that of the amp are harder to distinguish. I mostly listen to orchestral & chamber music, where large, but brief peaks come along among low average levels, and I find distortion in general more intrusive at lower levels.

And if we play LPs, surface defects can clip otherwise well-behaved music.

But the overall effect is very different between DC-coupled (fixed bias) versions - compared to RC-coupled grid-drive. Blocking distortion makes for cold and feeble sound, and I find it well worth the trouble of eliminating it.

...There are your new Source Follower boards coming up...

Oops! Sorry. I wrote that incorrectly. I meant your Shunt Cascode boards.

- Home

- Amplifiers

- Tubes / Valves

- Direct Coupled driver risks and dangers