~ ALL TRUE HALF'LER power amp(s) ~

The madness started a few years back, frustrated by limited amount of parts that will fit into an already tight chassis. Heat (increase) by added bias, by 2 heatsinks, *notable* increases in circuit dynamics, drive and power... these amps never have covers. My amps while reasonably biased, always run warm to hot... not crazy hot. They look and run cool(er) + I am always tinkering...

*I prefer mono amps* gear swapping, placement and cabling considerations. I built a few lop-sided chassis, with chassis pan and only one heat sink, devoting the entire supply to the one channel. *It would be easy to "do this" by simply pulling the fuse to other (unused) channel ~ but ~ the increase cost of added driver card, wiring, RCA jack and 5 wbp is somewhat offset, can be devoted to other projects... the real advantage for me was the abilities to built multiple chassis, with minor variations to test (hierarchically) what makes the greatest improvement, devoting the budget and efforts there. Having .many. individual loaded heatsinks, allowed me to model may ideas and narrow down a few things quickly, and very accurately.

Boutique audio caps are long absent from many builds, several audiophile friends [that have never heated a soldering iron] don't understand why I struggle with 20, 60, 100 dollar input coupling caps. One day (though, it may be near)

My first P-230 monos with Mundorf LOCO caps, far left image 3 (built inside a pair of Hafler P230 chassis) sounded SO GOOD, I have kept going, building on the idea, very much steeped in simplicity. I had started to have many idle parts on shelves... it dawned on me to use top cover(s) to build even more concept ideas with "parts that are idle", which means 4 more amp possibilities.

The benefits of using these amps covers allows me to have an even more sturdy chassis pan, that has NO PRE-DRILLED HOLES, allows me to place all "things" where I want them. I often have to lay things out in a sort of grid to pattern ideas of where the parts / my efforts are best directed, with so many ideas, too many ideas and the parts to render the ideas...

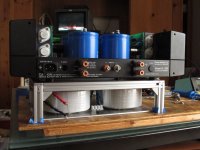

I think that these somewhat silly HALF'LER "200" upside down amps will sound very good... Will admit, I am pretty excited to mark-up the chassis's and start drilling/cutting metal. I have 2 DH500 power transformers [they may torque the chassis] will be used with 39K/100v capacitors, as shown. It'll be a beast, for sure.

I ask you? What would you do? What works best for you?

1) identical layouts

2) mirror image

or

3) leave em stereo

"and stack em high"

lols.

The madness started a few years back, frustrated by limited amount of parts that will fit into an already tight chassis. Heat (increase) by added bias, by 2 heatsinks, *notable* increases in circuit dynamics, drive and power... these amps never have covers. My amps while reasonably biased, always run warm to hot... not crazy hot. They look and run cool(er) + I am always tinkering...

*I prefer mono amps* gear swapping, placement and cabling considerations. I built a few lop-sided chassis, with chassis pan and only one heat sink, devoting the entire supply to the one channel. *It would be easy to "do this" by simply pulling the fuse to other (unused) channel ~ but ~ the increase cost of added driver card, wiring, RCA jack and 5 wbp is somewhat offset, can be devoted to other projects... the real advantage for me was the abilities to built multiple chassis, with minor variations to test (hierarchically) what makes the greatest improvement, devoting the budget and efforts there. Having .many. individual loaded heatsinks, allowed me to model may ideas and narrow down a few things quickly, and very accurately.

Boutique audio caps are long absent from many builds, several audiophile friends [that have never heated a soldering iron] don't understand why I struggle with 20, 60, 100 dollar input coupling caps. One day (though, it may be near)

My first P-230 monos with Mundorf LOCO caps, far left image 3 (built inside a pair of Hafler P230 chassis) sounded SO GOOD, I have kept going, building on the idea, very much steeped in simplicity. I had started to have many idle parts on shelves... it dawned on me to use top cover(s) to build even more concept ideas with "parts that are idle", which means 4 more amp possibilities.

The benefits of using these amps covers allows me to have an even more sturdy chassis pan, that has NO PRE-DRILLED HOLES, allows me to place all "things" where I want them. I often have to lay things out in a sort of grid to pattern ideas of where the parts / my efforts are best directed, with so many ideas, too many ideas and the parts to render the ideas...

I think that these somewhat silly HALF'LER "200" upside down amps will sound very good... Will admit, I am pretty excited to mark-up the chassis's and start drilling/cutting metal. I have 2 DH500 power transformers [they may torque the chassis] will be used with 39K/100v capacitors, as shown. It'll be a beast, for sure.

I ask you? What would you do? What works best for you?

1) identical layouts

2) mirror image

or

3) leave em stereo

"and stack em high"

lols.

Attachments

Last edited:

Design the best layout (there's only one), build, and repeat. No mirror images.

Later you can make a perf steel cover for the top and side.

Later you can make a perf steel cover for the top and side.

Last edited:

wisdom spoken

Thanks rayma (I follow / much appreciate your posts) I mirror the viewpoint shared.

I often layout out the chassis pan(s) and leave them on the table open, looking them over for days, until "it clicks" with me. As you say... there is *only one* right way.

I "admit" to a nearly OCD manner, wanting a clean chassis, with tidy / symmetrical wiring, often hidden or even buried. SO (for me) the wiring prospects often dictate that which follows.

Design the best layout (there's only one), build, and repeat. No mirror images.

Later you can make a perf steel cover for the top and side.

Thanks rayma (I follow / much appreciate your posts) I mirror the viewpoint shared.

I often layout out the chassis pan(s) and leave them on the table open, looking them over for days, until "it clicks" with me. As you say... there is *only one* right way.

I "admit" to a nearly OCD manner, wanting a clean chassis, with tidy / symmetrical wiring, often hidden or even buried. SO (for me) the wiring prospects often dictate that which follows.

While doing the juggle

I had only been focusing on the 8 (possible) mono chassis.

With an XL280 in the back ground [wanting some attention]

I am swapping, power modules / with TO-3 / TO-264 devices

Higher and lower voltage P/S and output stages power sorted,

trying to coordinate a complex evolutionary puzzle,

with intent on learning (more).

I had a few transformers that were "out of place", I was limited

in what I could do with them [ after shortening the leads ]

So this long standing idea hit me.

Pictures are worth a thousand words. Needless to say

I have stopped working on all other projects

to run with this long standing idea.

Funny how solutions unfold right before our eyes...

No wonder my shins are bruised and sore, lols.

I had only been focusing on the 8 (possible) mono chassis.

With an XL280 in the back ground [wanting some attention]

I am swapping, power modules / with TO-3 / TO-264 devices

Higher and lower voltage P/S and output stages power sorted,

trying to coordinate a complex evolutionary puzzle,

with intent on learning (more).

I had a few transformers that were "out of place", I was limited

in what I could do with them [ after shortening the leads ]

So this long standing idea hit me.

Pictures are worth a thousand words. Needless to say

I have stopped working on all other projects

to run with this long standing idea.

Funny how solutions unfold right before our eyes...

No wonder my shins are bruised and sore, lols.