I've done quite a lot of measurement with mine and honestly, I don't think there is much diffeece with using two ring magnets or one ring and many cylinder magnets.

YNWOAN, what did you do for a tonearm on yours?

I was also wondering how much I have to spend to get a decent tonearm? That Jelco one is about 450 bucks. If I can get something decently good for like 200-250 I'd rather go that route and spend more on the cartridge.

I was also wondering how much I have to spend to get a decent tonearm? That Jelco one is about 450 bucks. If I can get something decently good for like 200-250 I'd rather go that route and spend more on the cartridge.

The arm on mine is a Naim ARO.

The chassis is a carbon fibre, Nomex laminate.

The main plinth section is in two layers and is separated by an oil damped sprung suspension (these suspension elements can not be seen in the pic). The deck is built into the stand.

The suspension elements you can see are a secondary level of suspension.

An externally hosted image should be here but it was not working when we last tested it.

The chassis is a carbon fibre, Nomex laminate.

The main plinth section is in two layers and is separated by an oil damped sprung suspension (these suspension elements can not be seen in the pic). The deck is built into the stand.

An externally hosted image should be here but it was not working when we last tested it.

(sorry about the dust)The suspension elements you can see are a secondary level of suspension.

Is your platter aluminum? Also this carbon fiber/Nomex laminate did you do that your self or did you buy the material somewhere?

The platter is made from Mazak.

The carbon fibre, Nomex laminate was sourced through a chap I knew who worked for British Aerospace in the materials testing department - I believe it is called Fibrelam (but could be wrong as there are a number of different versions). I have also come across glass fibre skins with Nomex core and versions with an aluminium core and/or skins. It is possible to make your own as I believe it is an expensive product. The advantage of the CF/Nomex combination is its extremely high stiffness to mass ratio and self damping properties. I use two layers which are bonded to form a constrain layer damped structure.

The carbon fibre, Nomex laminate was sourced through a chap I knew who worked for British Aerospace in the materials testing department - I believe it is called Fibrelam (but could be wrong as there are a number of different versions). I have also come across glass fibre skins with Nomex core and versions with an aluminium core and/or skins. It is possible to make your own as I believe it is an expensive product. The advantage of the CF/Nomex combination is its extremely high stiffness to mass ratio and self damping properties. I use two layers which are bonded to form a constrain layer damped structure.

YNWOAN,, yes!

The Verdier s have full magnetic "levitation". The "decreased load" thing is something that many others have tried, some successfully, some less so.

Calculations could be done regarding the proposed platter mass, and the strength of the field, prior to any building begins.

stew

The Verdier s have full magnetic "levitation". The "decreased load" thing is something that many others have tried, some successfully, some less so.

Calculations could be done regarding the proposed platter mass, and the strength of the field, prior to any building begins.

stew

I had an idea for a speed control. I figure I could hook up the motor and what not and then get a potentiometer and hook it up and use the strobes to find the correct speed for 45rpm and then measure what the resistance is on the pot and do the same for 33.3 rpm and then wire up a switch with something close to the 2 resistances probably a bit less then what was required. After that would be a small pot for fine adjustments on each. Possibly build this into a power supply box or something.

I was also wondering is there anything wrong with going direct drive on an audiophile grade TT?

I was also wondering is there anything wrong with going direct drive on an audiophile grade TT?

Presumably you are thinkng of using a DC motor.

There are lots of issues with going with DD, mostly these relate to motor noise and speed stability. However, all of these can be solved if you have sufficient money and engineering ability. Look up Grand Prix Audio who make a DD high end turntable - they have written a White Paper which outlines the development and design ethos of their turntable.

http://www.grandprixaudio.com/

http://www.grandprixaudio.com/prod_monaco_turntable.php

By far the cheapest way of achieving quality DD would be to buy a Technics 1200/1210 and strip the motor section from it.

There is also this: http://www.teresaudio.com/certus/index.html

I've just read the Teres White Paper and it really is most interesting - thoroughly recomended.

There are lots of issues with going with DD, mostly these relate to motor noise and speed stability. However, all of these can be solved if you have sufficient money and engineering ability. Look up Grand Prix Audio who make a DD high end turntable - they have written a White Paper which outlines the development and design ethos of their turntable.

http://www.grandprixaudio.com/

http://www.grandprixaudio.com/prod_monaco_turntable.php

By far the cheapest way of achieving quality DD would be to buy a Technics 1200/1210 and strip the motor section from it.

There is also this: http://www.teresaudio.com/certus/index.html

I've just read the Teres White Paper and it really is most interesting - thoroughly recomended.

I'll probably just go belt drive. Do you think that would work for controlling the motor speed? Or might it cause problems? I'd probably try and use a DC motor as I suppose they are less noisy then AC. But I think it could work decently. The fine tuning should be able to get it pretty dead on speed wise. Are there like special strobe you use for tuning the turntable speed?

Dougie085 said:Is there a special strobe you use for tuning the turntable speed?

Yes. Use a red high brightness LED.

Attachments

Read the Teres White paper for a really interesting view of the pros and cons relating to DC and AC motors. If I were you I would build the strobe EC8010 has posted - I use a similiar strobe.

You could start with an AC motor, which is easy (and almost certainly cheaper) to implement, and then alter your deign to include a DC motor. That way you can make your own decision as to which is best.

You could start with an AC motor, which is easy (and almost certainly cheaper) to implement, and then alter your deign to include a DC motor. That way you can make your own decision as to which is best.

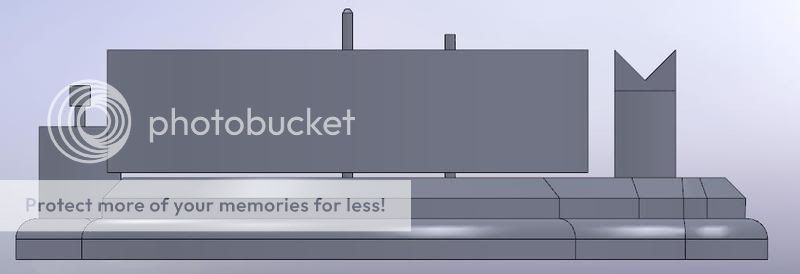

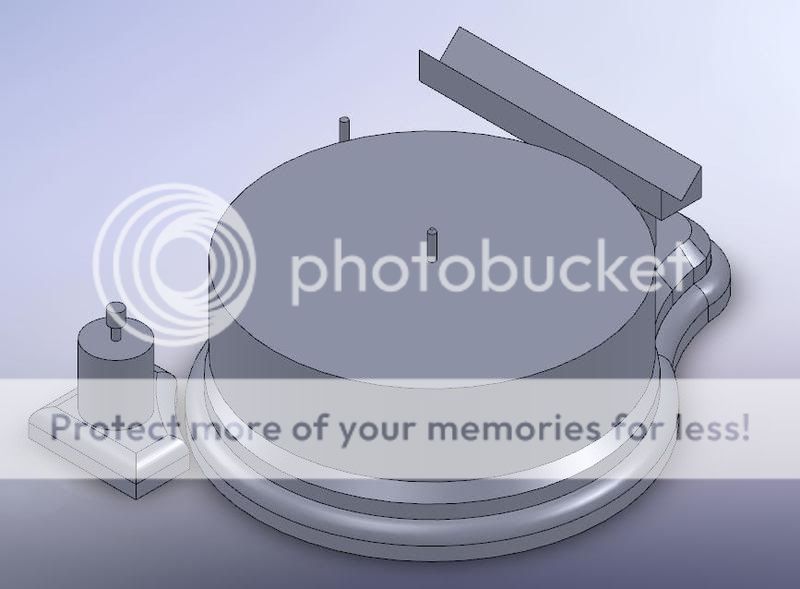

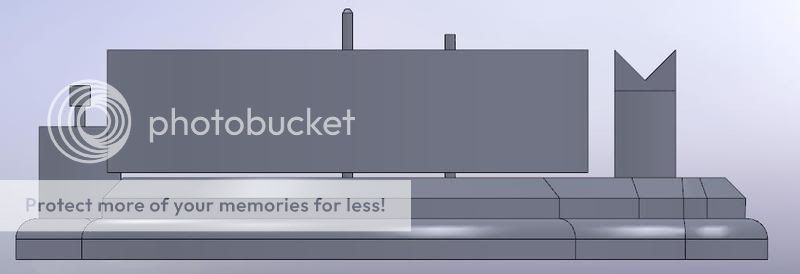

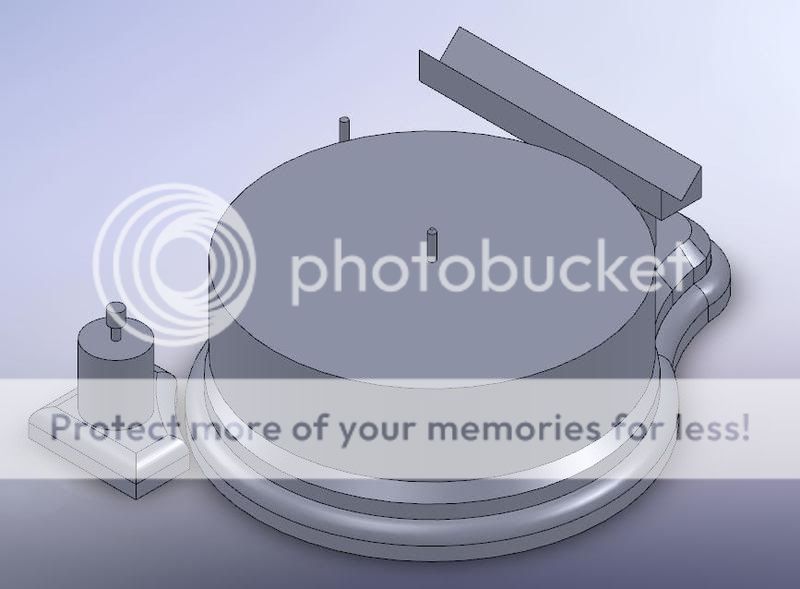

I spent a little more time on the design of the TT it self today. I did some renderings in Solidworks. I think it looks nice. I didn't draw in the tonearm yet I have to figure out where and how I'm going to do that. Obviously there isn't a space between the platter and the base this was just kind of a quick rendering. The platter is 3" thick on this one.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

That looks interesting but you still have (I'm sure you know this) so many issues to resolve; I hope you are not in danger of working from the outside in. The specific manner in which the arm is mounted and integrated into the turntable does make a significant difference (in my experience). Then there is motor isolation, mounting, drive geometry, bearing structure and specific design etc. not to mention an isolation system (if you are having any). I would solve all these issues and see what form comes out of them myself. I'm looking forward to the next instalment though  🙂

🙂

🙂

🙂Thinking about magnetic isolation feet as well. As for the arm its going to be that linear tracking arm so regardless of where I put it just gotta make sure it has a straight line. I'm not sure what you mean by motor isolation exactly? Vibrations maybe? If so probably would have a rubber/foam cup that goes into the wood and then the motor slides in. I'm not really sure. Does the motor make that much vibrations? If so maybe I'll have the motor in a different block. If its shielding I've got some idea's for that as well. This is just a small sketch to get some of my idea's together.

Ok took some of what you said into consideration and redid it a bit.

Now the motor will not be attached to the actual TT so the vibrations shouldn't bother it any. Also drew part of the tonearm so you could see where it would go. There is a pole sticking up... Not sure how to draw what I want but it would be where the tone arm rests when not used. I was looking for platter bearings and all I could find was the 300 dollar bearing from Teres. This is why I want to try and do the magnets. Reason I don't is I don't want to have issues with MC cartridges and what not. I'm also thinking about building the platter out of solid bamboo plywood. It's 3/4" and would do 4 layers. I think it could turn out pretty nice.

Now the motor will not be attached to the actual TT so the vibrations shouldn't bother it any. Also drew part of the tonearm so you could see where it would go. There is a pole sticking up... Not sure how to draw what I want but it would be where the tone arm rests when not used. I was looking for platter bearings and all I could find was the 300 dollar bearing from Teres. This is why I want to try and do the magnets. Reason I don't is I don't want to have issues with MC cartridges and what not. I'm also thinking about building the platter out of solid bamboo plywood. It's 3/4" and would do 4 layers. I think it could turn out pretty nice.

I use an (very expensive) expensive moving coil cartridge and have had absolutely zero issues with using it with my magnetic bearing, if that reasures you any.

Do you think 2 of these would work for a 3" thick platter? I'm guessing around 25lbs?

http://www.magnet4less.com/product_info.php?cPath=1_13&products_id=321

http://www.magnet4less.com/product_info.php?cPath=1_13&products_id=321

I was looking at options for motors. This guy used a 7.5 deg stepper motor. My only issue with this is that he used a computer sound card to control it. Isn't there a PSU or something you can build that sends the correct frequency signals (50 or 60hz) that you can also add pots for fine tuning something like this instead of feeding it sine waves from your computer?

This is the TT I'm talking about http://www.altmann.haan.de/turntable/

This is the TT I'm talking about http://www.altmann.haan.de/turntable/

I would certainly hope that those magnets you have posted a link to would be strong enough (my platter weighs about 8.5lb) - quite a bit too strong I suspect. In addition, I'm afraid I will have to take back some of my 'don't worry about magnetic interference' reassurance. If the platter is only going to be only 3 inches thick you are going to get a really strong radiated field from those magnets.

Yes I did mean motor noise - the motor is one of THE main sources of vibration/ noise pollution in a turntable.

I wouldn't personally use a stepper motor for this application. I have used them in the past for other (non turntable) projects and have always used a computer to control them in that situation.

My cartridge is no longer in production but it would certainly be in the $2000+ range if it were (even second hand they sell for approx $1000). However, the price is not relevant, my point is just to say that I wouln't risk my MC if I thought there was a problem

Yes I did mean motor noise - the motor is one of THE main sources of vibration/ noise pollution in a turntable.

I wouldn't personally use a stepper motor for this application. I have used them in the past for other (non turntable) projects and have always used a computer to control them in that situation.

My cartridge is no longer in production but it would certainly be in the $2000+ range if it were (even second hand they sell for approx $1000). However, the price is not relevant, my point is just to say that I wouln't risk my MC if I thought there was a problem

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Designing a DIY TT