I have one of these with a flickering speed lock light and audibly high wow&flutter. I’ve replaced all the electrolytic caps as well as two notorious 2023 transistors but still have the problem. I can’t seem to get steady motor control behavior on the oscilloscope, and I have a soft rubbing sound when the motor is on (don’t get it when spinning the platter by hand). Anyone have suggestions for what to try next? Thanks much.

Thinking the head might be the rub, I backed it way off until it was clear there was no way it could rub but still got the noise (platter ran warp speed of course). Disassembled motor and found it pretty dry with some crud around thrust bearing. Armature also has some scratches but I’m afraid to touch it even with 2000 grit so I guess I’ll just clean, lube, and reassemble. Pickup head is scratched up and has some corrosion so I think I’ll try to find one on the bay and replace it. Any suggestions appreciated…

Attachments

I have a DP59L in storage that shows a similar issue. I will get it out of storage and on the bench in 10 days. Happy to share my experiences as soon as I start work on it.

Finally got the DP59L on to the bench. There is no noise if I spin the platter by hand - it rotates silently and smoothly. Not so if I select 33rpm (or 45rpm) - there is noise, almost as if something is just scraping the platter. Applying the oscilloscope, Test Point 2 showed a triangular wave with a slow rise and sharp fall with 4V amplitude, just as the DP59L service manual depicts. Test point 1 showed a very noisy waveform, punctuated by pulses of lower magnitude. I would post the photo of the traces but it was flash-lit junk - sorry.

I then checked all power supply voltages - they closely matched the values on the schematic (+5.0V 0v -5.0V and +8.4V 0V -10.0V). I checked continuity to the motor control and phase lock loop ICs - all good. I checked continuity to all test points - all good.

I then adjusted the tonearm controls (Test Points 3, 4, 301, 302 and 304) to specification.

Then I reviewed the magnetic detection head which reads the 1000 pulses magnetically coded on the inner circumference of the platter. I noticed that the gap between the head and the rim was approximately 0.3mm (estimated by inserting paper and then measuring the paper thickness with a micrometer) whereas Denon recommended setting the gap to 0.18mm. It was also slightly askew. I adjusted the gap (paper and micrometer again - don't want to scratch the head or the platter) and straightened the head.

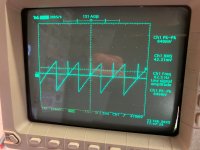

I then returned to the oscilloscope and Test Points 1 and 2, which gave the trace attached - much closer to the specs in the Denon service manual. The trace shown is for 45rpm after adjusting the wave-forms with Variable Resistor 2 (VR2 on the PCB). I noticed that the amount of adjustment was limited - at the extremes, the phase lock loop would not settle and the "Lock" indicator LED adjacent to the power switch would flutter. The slight scraping noise was gone. I repeated the procedure for 33rpm, with good results.

After adjustment, the RPM turntable speed app on my iPhone showed the rotational speed on the 45rpm setting was correct to 0.00% with 0.10% wow and flutter, while the 33.33rpm setting was down -0.01% with wow and flutter of 0.09%.

Wow and flutter are not audible, the turntable is quiet.

I then checked all power supply voltages - they closely matched the values on the schematic (+5.0V 0v -5.0V and +8.4V 0V -10.0V). I checked continuity to the motor control and phase lock loop ICs - all good. I checked continuity to all test points - all good.

I then adjusted the tonearm controls (Test Points 3, 4, 301, 302 and 304) to specification.

Then I reviewed the magnetic detection head which reads the 1000 pulses magnetically coded on the inner circumference of the platter. I noticed that the gap between the head and the rim was approximately 0.3mm (estimated by inserting paper and then measuring the paper thickness with a micrometer) whereas Denon recommended setting the gap to 0.18mm. It was also slightly askew. I adjusted the gap (paper and micrometer again - don't want to scratch the head or the platter) and straightened the head.

I then returned to the oscilloscope and Test Points 1 and 2, which gave the trace attached - much closer to the specs in the Denon service manual. The trace shown is for 45rpm after adjusting the wave-forms with Variable Resistor 2 (VR2 on the PCB). I noticed that the amount of adjustment was limited - at the extremes, the phase lock loop would not settle and the "Lock" indicator LED adjacent to the power switch would flutter. The slight scraping noise was gone. I repeated the procedure for 33rpm, with good results.

After adjustment, the RPM turntable speed app on my iPhone showed the rotational speed on the 45rpm setting was correct to 0.00% with 0.10% wow and flutter, while the 33.33rpm setting was down -0.01% with wow and flutter of 0.09%.

Wow and flutter are not audible, the turntable is quiet.

Attachments

Thanks for this awesome write up, bondini, and glad all yours required was readjustment of the pickup. A fellow on another forum suggested disconnecting the brake circuit temporarily to see if that would stabilize the triangle wave so I will try that next.

Thanks for the post Bondini! This helped immensely. I was having similar issues getting a clean signal on my oscilloscope. I never adjusted the head gap since I couldn't find the spec in the service manual scan I have.

Thanks to your post, my Denon is now performing as it should. While I have a DP-62L instead of a DP-59L, the design is similar enough for your information to apply.

Thanks to your post, my Denon is now performing as it should. While I have a DP-62L instead of a DP-59L, the design is similar enough for your information to apply.

Attachments

Last edited:

Good work! If I had to bet I would say the magnets have lost some magnetism. That is why once it was able to work correctly with a 0.3 mm gap. I don't know the exact construction, but it seems to me the magnets on the magnetic strip have their field lines running thru the air. Not shorted in any way with magnetic material. That weakens the magnets over time.

In my specific case, the head gap was set to almost 1mm.

This just happened to be the first time I have ever needed to touch the head gap. On other Denon turntables, I usually just encounter poorly adjusted tonearms. Occasionally a bad capacitor or cds photocell.

This just happened to be the first time I have ever needed to touch the head gap. On other Denon turntables, I usually just encounter poorly adjusted tonearms. Occasionally a bad capacitor or cds photocell.

I was given the DP59L - it had been dropped and needed work. It was rbstroub's post that prompted me to go to work on it. I think it is the fourth Denon direct drive I have had and I find them to be very good, though not without the kinds of problems common to 40 year old electronics. Regardless, I prefer them to the belt drive turntables I have owned (including a Linn) and idler wheel turntables (noting that I use a Thorens TD135 to play 78s).

After many years of trial and error (lots of errors) I favour MM cartridges on the Denon Servo-Tracer tonearm and yes, I have used other tonearms (Grace, Jelco etc) and MC cartridges.

What I would love to see is a new DD turntable with advanced motor drive and feedback - I find the Korf blog fascinating (https://korfaudio.com/blog97 I would love to have their proprietary speed measurement kit) and promising, Until that promise comes to fruition, it would seem sensible to audition the Technics SL1300G and the Denon DP3000NE before my turntables are beyond maintaining and repairing ....

After many years of trial and error (lots of errors) I favour MM cartridges on the Denon Servo-Tracer tonearm and yes, I have used other tonearms (Grace, Jelco etc) and MC cartridges.

What I would love to see is a new DD turntable with advanced motor drive and feedback - I find the Korf blog fascinating (https://korfaudio.com/blog97 I would love to have their proprietary speed measurement kit) and promising, Until that promise comes to fruition, it would seem sensible to audition the Technics SL1300G and the Denon DP3000NE before my turntables are beyond maintaining and repairing ....

- Home

- Source & Line

- Analogue Source

- Denon DP-59L speed control