I got lucky last weekend, & found a pair of KEF C40s on the side of the road. Someone had stuck a piece of veneered chipboard on the top of each, presumably so they could put a nice pot plant there, and they had obviously been stored somewhere damp, given the light coating of mould.

I didn’t want them in the workshop in this condition, so when I got home immediately wiped them down with vinegar to kill the mould (fortunately no moisture damage), cleaned them with detergent, and the hot day made it easy to remove the ‘pot plant stands’. I removed the components, and then attacked the sticky residue left on the vinyl with solvent.

The boxes ended up in usable condition, with some nicks & chips, and obligatory spatter of white paint droplets. There was a convenient date stamp inside showing them to be from Apr 1987. Someone must have told KEF to get stuffed, these were sealed and absolutely chocka with polyfill.

The components: the crossover were clean, although with 38 years under their belt it’s time for a recap of the five electrolytics. The woofers cleaned up nicely and are in good condition; the tweeter coatings were bad, almost completely gone from one, seriously cracked on the other.

The plan: take measurements, re-cap the x-over, and re-coat the tweeters, Re-assemble to see how speakers from the ‘Golden Age’ sound, keep them if I like them, otherwise flog them on Gumtree (I need more speakers like a hole in the head).

I didn’t want them in the workshop in this condition, so when I got home immediately wiped them down with vinegar to kill the mould (fortunately no moisture damage), cleaned them with detergent, and the hot day made it easy to remove the ‘pot plant stands’. I removed the components, and then attacked the sticky residue left on the vinyl with solvent.

The boxes ended up in usable condition, with some nicks & chips, and obligatory spatter of white paint droplets. There was a convenient date stamp inside showing them to be from Apr 1987. Someone must have told KEF to get stuffed, these were sealed and absolutely chocka with polyfill.

The components: the crossover were clean, although with 38 years under their belt it’s time for a recap of the five electrolytics. The woofers cleaned up nicely and are in good condition; the tweeter coatings were bad, almost completely gone from one, seriously cracked on the other.

The plan: take measurements, re-cap the x-over, and re-coat the tweeters, Re-assemble to see how speakers from the ‘Golden Age’ sound, keep them if I like them, otherwise flog them on Gumtree (I need more speakers like a hole in the head).

Attachments

The Woofers ‘SP1205’

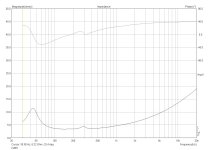

These are interesting. They are clearly very efficient although the magnets are tiny and the poly cones are very thin. I’m not surprised that poly drivers of the time had a reputation for distortion. The surround is some sort of vinyl rather than foam or rubber. Being nominally 3 ohms, they were clearly designed to be used in pairs. The impedance plot shows an interesting hump at around 300Hz on all four.

Measurements (For brevity I’ll just give the mean of all 4, they’re quite consistent):

Re: 2.85, Fs: 40.5, Le 0.975, Qm: 2.27, Qe: .71, Qt: .54 (thought it would be higher), Vas (measured on only one driver) 76.33.

For the hell of it, I simmed these in Unibox for both the existing 28L box, and a ported alignment in 80L.

Some have called these ‘B200s’, and although KEF appeared to call any 8” driver of the period a B200, I can find no data sheet with the SP1205 designation.

These are interesting. They are clearly very efficient although the magnets are tiny and the poly cones are very thin. I’m not surprised that poly drivers of the time had a reputation for distortion. The surround is some sort of vinyl rather than foam or rubber. Being nominally 3 ohms, they were clearly designed to be used in pairs. The impedance plot shows an interesting hump at around 300Hz on all four.

Measurements (For brevity I’ll just give the mean of all 4, they’re quite consistent):

Re: 2.85, Fs: 40.5, Le 0.975, Qm: 2.27, Qe: .71, Qt: .54 (thought it would be higher), Vas (measured on only one driver) 76.33.

For the hell of it, I simmed these in Unibox for both the existing 28L box, and a ported alignment in 80L.

Some have called these ‘B200s’, and although KEF appeared to call any 8” driver of the period a B200, I can find no data sheet with the SP1205 designation.

Attachments

The Crossovers:

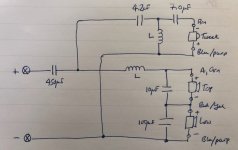

Fortunately I found the attached schematic online, which I can confirm is correct.

Measurements of the inductors show the tweeter inductor to be 0.24mH, and the woofer leg inductor to be 1.275mH. The tweeter xover is electrically 3rd order, whereas the woofers are in an interesting 2.5 way series configuration with the upper frequency determined by a parallel cap. They also have a 450uF series cap to get some more lows at the resonant freq.

How did the old caps hold up after 38 yrs?

Nominal #1 #2

450uF 508 504

100 115 141*

10 11.2 11

7 7.9 14.6*

4.2 4.47 4.68

Interestingly the asterisked caps are branded ‘Bennic’, which was a preferred audiophile upgrade for a while. They haven’t fared as well as the plain vanilla ‘Alcaps’ – let that be a lesson to you young audiophile….

When recapping, I will be taking some liberties with the values, the boards are too small for multiple caps to achieve odd numbers, so 4.2 will be 4.7 (at least initially); 7 will become 6.8; and 450 will be 2x 1000uF in series.

Fortunately I found the attached schematic online, which I can confirm is correct.

Measurements of the inductors show the tweeter inductor to be 0.24mH, and the woofer leg inductor to be 1.275mH. The tweeter xover is electrically 3rd order, whereas the woofers are in an interesting 2.5 way series configuration with the upper frequency determined by a parallel cap. They also have a 450uF series cap to get some more lows at the resonant freq.

How did the old caps hold up after 38 yrs?

Nominal #1 #2

450uF 508 504

100 115 141*

10 11.2 11

7 7.9 14.6*

4.2 4.47 4.68

Interestingly the asterisked caps are branded ‘Bennic’, which was a preferred audiophile upgrade for a while. They haven’t fared as well as the plain vanilla ‘Alcaps’ – let that be a lesson to you young audiophile….

When recapping, I will be taking some liberties with the values, the boards are too small for multiple caps to achieve odd numbers, so 4.2 will be 4.7 (at least initially); 7 will become 6.8; and 450 will be 2x 1000uF in series.

Attachments

The Tweeters:

The challenge here is to recoat these. (Pic is halfway during cleaning).

Removal of the old coating – I initially tried Shellite, but Turps seems too work better because it doesn’t flash off as quickly.

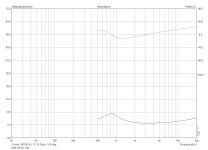

At this stage, they’re showing a reasonably benign impedance curve, both with Re of 6.5 ohms, Fs of 815Hz and 717Hz.

Online searching show some had had success in using Shellac for the recoat, but I think it needs to be a bit more flexible than that. Thanks to Stuey for his suggestion of acrylic artists pouring medium which looks to be more suitable, if I can get it on thin enough.

The challenge here is to recoat these. (Pic is halfway during cleaning).

Removal of the old coating – I initially tried Shellite, but Turps seems too work better because it doesn’t flash off as quickly.

At this stage, they’re showing a reasonably benign impedance curve, both with Re of 6.5 ohms, Fs of 815Hz and 717Hz.

Online searching show some had had success in using Shellac for the recoat, but I think it needs to be a bit more flexible than that. Thanks to Stuey for his suggestion of acrylic artists pouring medium which looks to be more suitable, if I can get it on thin enough.

Attachments

Tweeter coatings experiments. Found some gauzey material to paint this goop onto.

Left to right: Left:Byron fabric medium mixed with Acrylic poster paint & water (seems too thick & would need to be almost 100% paint to get good colour)

Middle: Fabric medium with a splurge of printer ink (I'd mixed up some brown for a previous project) - good consistency, but the colour's a bit baby excrement yellow

Right: straight Feast Watson shellac based 'French Polish' - seems to have the thinnest consistency, probably easiest to get a thin coating.

I'm off to NZ for a few days, I'll see how they've dried when I get back

Left to right: Left:Byron fabric medium mixed with Acrylic poster paint & water (seems too thick & would need to be almost 100% paint to get good colour)

Middle: Fabric medium with a splurge of printer ink (I'd mixed up some brown for a previous project) - good consistency, but the colour's a bit baby excrement yellow

Right: straight Feast Watson shellac based 'French Polish' - seems to have the thinnest consistency, probably easiest to get a thin coating.

I'm off to NZ for a few days, I'll see how they've dried when I get back

Attachments

Next day & the unadulterated Fabric medium looks like the top contender, dries clear without the brittleness of the shellac

It is a nice looking tower

Wasn't paying attention and searched for T/S parameters.

Seeing a few pictures and smaller magnet size assumed high Qts. Maybe good sealed with better transient with 2x woofers.

Then noticed you had posted T/S values and yup high Qts.

Sealed stuffed to holy heck with poly be the best, seems like exactly what they did.

Tweeter seems pretty good low Fs

Kef used a 3rd order it seems, not too bad for higher listening level distortion.

Like it, sealed box stuffed tight. Pretty fun speaker.

Nice benefit that the surround material on the woofers held up.

For tweeter coating, wonder if Visaton's LTS50 treatment would work.

It is noted as a actual treatment not just a dye. for improved damping/oscillation reduction of paper cones.

I'm interested in your homebrew experiments as well.

Wonder if something latex as opposed to just acrylic would have benefit for flexibility of a surround.

Somewhere around here was a thread about a surround treatment, which was flexible like latex.

But had other magic science stuff to perform better than latex properties.

I also wonder what the formula is used for cloth edge/M roll type speaker re cones and manufacturing.

The cloth surround is sealed after gluing, and is some sort of magic black goop as well.

I know as well for less pooling or surface tension blotching when watering down water based glue or paints.

Model railroaders will add alcohol to watered down glue for smoother even coverage.

Wasn't paying attention and searched for T/S parameters.

Seeing a few pictures and smaller magnet size assumed high Qts. Maybe good sealed with better transient with 2x woofers.

Then noticed you had posted T/S values and yup high Qts.

Sealed stuffed to holy heck with poly be the best, seems like exactly what they did.

Tweeter seems pretty good low Fs

Kef used a 3rd order it seems, not too bad for higher listening level distortion.

Like it, sealed box stuffed tight. Pretty fun speaker.

Nice benefit that the surround material on the woofers held up.

For tweeter coating, wonder if Visaton's LTS50 treatment would work.

It is noted as a actual treatment not just a dye. for improved damping/oscillation reduction of paper cones.

I'm interested in your homebrew experiments as well.

Wonder if something latex as opposed to just acrylic would have benefit for flexibility of a surround.

Somewhere around here was a thread about a surround treatment, which was flexible like latex.

But had other magic science stuff to perform better than latex properties.

I also wonder what the formula is used for cloth edge/M roll type speaker re cones and manufacturing.

The cloth surround is sealed after gluing, and is some sort of magic black goop as well.

I know as well for less pooling or surface tension blotching when watering down water based glue or paints.

Model railroaders will add alcohol to watered down glue for smoother even coverage.

Last edited:

I just gave them a coat of Fabric Medium, looks OK & should be nice & dry when I return in 4 days. I'll give them a listen then & see if they need another coat. The Visaton stuff is water soluble, so I don't think it is too different from what I'm using. Re: 'towers' - these are 65cm high, so I'll make some stands to add ~another foot if they sound good, to get the tweeter height reasonable

- Home

- Loudspeakers

- Multi-Way

- Deconstructing KEF C40s