Hi. Weve moved house recently and the new listening room is much smaller than the old one. My BIBs with TB W5-1611 are sounding very different. No bass, all mids. No big surprice really since I tuned them specifically for the old room

So its time for a newer design 🙂 Im quite fascinated with the Cornu. Two different length horns, big baffle, wall mounted. That plus wall + floor boundary for bass extension ie, making the horn much bigger. And minus the spiral since Im guessing the length would suffice anyway?

Heres some points that summarizes my ideas for the new speaker:

• Very thin and mounted on wall for practical reasons

• Wide baffle for nice transition of baffle step and horn output

• Back loaded horn with two different and offset length horns

• Wall, ceiling + floor boundary loading like Cornu/Klipsch

• Built mostly with styrofoam blocks for the weight. Plus its easier

Ive attached a sketch with dimensions. Chamber volume and design + the horn flare is completely arbitrary. I have no idea what would be good choice for that

What do you think? Would it work as planned?

Regards /Bo

So its time for a newer design 🙂 Im quite fascinated with the Cornu. Two different length horns, big baffle, wall mounted. That plus wall + floor boundary for bass extension ie, making the horn much bigger. And minus the spiral since Im guessing the length would suffice anyway?

Heres some points that summarizes my ideas for the new speaker:

• Very thin and mounted on wall for practical reasons

• Wide baffle for nice transition of baffle step and horn output

• Back loaded horn with two different and offset length horns

• Wall, ceiling + floor boundary loading like Cornu/Klipsch

• Built mostly with styrofoam blocks for the weight. Plus its easier

Ive attached a sketch with dimensions. Chamber volume and design + the horn flare is completely arbitrary. I have no idea what would be good choice for that

What do you think? Would it work as planned?

Regards /Bo

Attachments

Danerius,

Neat design. Give me some time to set this up in Akabak. I may go with conical horns at first and then progress to exponential. It should prove interesting. I am wondering if having the two horns end to end will present a full wave double open ended tube boundary condition rather than a 1/4 wave or 1/2 wave. Maybe the throat breaks it up? Perhaps a protrusion to prevent a direct line of sight may delineate the twohorn boundaries? I will keep you posted as soon as I have something. Are you really stuck on the W5-1611 driver?

Regards,

X

Neat design. Give me some time to set this up in Akabak. I may go with conical horns at first and then progress to exponential. It should prove interesting. I am wondering if having the two horns end to end will present a full wave double open ended tube boundary condition rather than a 1/4 wave or 1/2 wave. Maybe the throat breaks it up? Perhaps a protrusion to prevent a direct line of sight may delineate the twohorn boundaries? I will keep you posted as soon as I have something. Are you really stuck on the W5-1611 driver?

Regards,

X

Sim of DBLH

Daneris,

Here are some results from my initial model of the DBLH given the parameters you specified. The nominal lengths for the horns did not yield very deep bass extension - only down to 100 Hz. I believe it is due to the concern I had that it would appear as a long double-open ended tube which is only a half-wave resonator, whereas a quarter wave resonator gets you down twice as deep. As a result the horn lengths essentially had to be doubled to get bass down in the 40 to 50 Hz region. This means that you will have to fold your horn line at least once. This is typical for double horns - which are folded many times to keep their size manageable.

The geometry I ended up with is as follows dimensions are in inches multiplied by meters/in (Depth was kept at 3.54 in or 90 mm):

So the upward pointing horn is 120 in long with a mouth of 40 in and downward is 95 inches long with a mouth of 25 inches. They both started with a 3 in throat fed by a common 4.2 in throat from a 3 liter driver volume chamber.

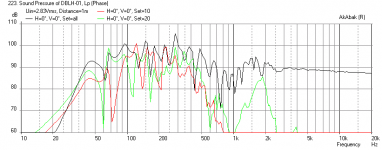

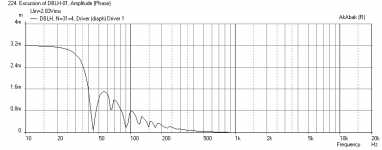

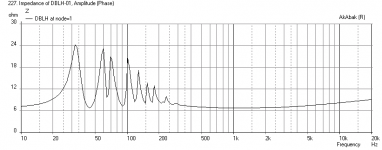

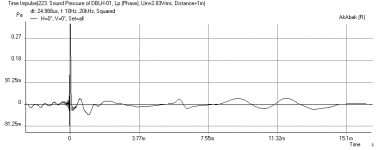

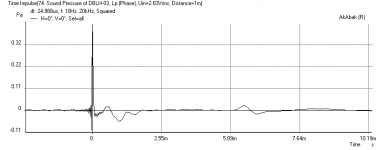

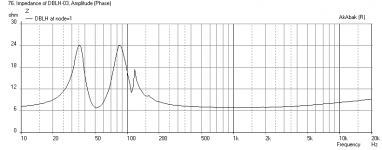

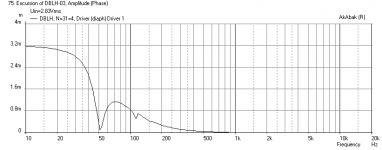

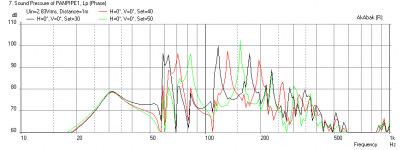

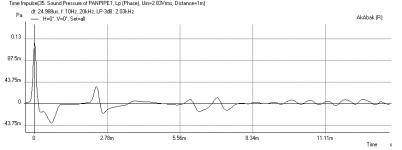

The sims are for 1 watt at 1 m and show freq response (red is long horn, green is short horn, black is combined with driver radiation), cone displacement, impedance, and impulse response. The impedance plots of double horns is very interesting - you can see the non-linear interactions of one horn with another. What is interesting is that lengthening the shorter horn decreases the frequency extension on long horn output - clearly showing an interaction of how this behaves like a double open ended resonator - which it is.

I did not have too much time to optimize for flat response - later...

Daneris,

Here are some results from my initial model of the DBLH given the parameters you specified. The nominal lengths for the horns did not yield very deep bass extension - only down to 100 Hz. I believe it is due to the concern I had that it would appear as a long double-open ended tube which is only a half-wave resonator, whereas a quarter wave resonator gets you down twice as deep. As a result the horn lengths essentially had to be doubled to get bass down in the 40 to 50 Hz region. This means that you will have to fold your horn line at least once. This is typical for double horns - which are folded many times to keep their size manageable.

The geometry I ended up with is as follows dimensions are in inches multiplied by meters/in (Depth was kept at 3.54 in or 90 mm):

Code:

| Define Horn Segments (need to multiply by Depth for area): S_Throat, S_Mouth, Length

| Shared Throat Segment

S0T=4.2*0.0254; S0M=4.21*0.0254; L0=2.00*0.0254; | Reduced throat to control HF escaping

| First Horn points up

S1T=3.00*0.0254; S1M=40.0*0.0254; L1=120*0.0254;

| Second Horn points down

S2T=3.00*0.0254; S2M=25.0*0.0254; L2=95*0.0254;So the upward pointing horn is 120 in long with a mouth of 40 in and downward is 95 inches long with a mouth of 25 inches. They both started with a 3 in throat fed by a common 4.2 in throat from a 3 liter driver volume chamber.

The sims are for 1 watt at 1 m and show freq response (red is long horn, green is short horn, black is combined with driver radiation), cone displacement, impedance, and impulse response. The impedance plots of double horns is very interesting - you can see the non-linear interactions of one horn with another. What is interesting is that lengthening the shorter horn decreases the frequency extension on long horn output - clearly showing an interaction of how this behaves like a double open ended resonator - which it is.

I did not have too much time to optimize for flat response - later...

Attachments

Last edited:

Daneris,

Here are some results from my initial model of the DBLH given the parameters you specified. The nominal lengths for the horns did not yield very deep bass extension - only down to 100 Hz. I believe it is due to the concern I had that it would appear as a long double-open ended tube which is only a half-wave resonator, whereas a quarter wave resonator gets you down twice as deep. As a result the horn lengths essentially had to be doubled to get bass down in the 40 to 50 Hz region. This means that you will have to fold your horn line at least once. This is typical for double horns - which are folded many times to keep their size manageable.

The geometry I ended up with is as follows dimensions are in inches multiplied by meters/in (Depth was kept at 3.54 in or 90 mm):

Code:| Define Horn Segments (need to multiply by Depth for area): S_Throat, S_Mouth, Length | Shared Throat Segment S0T=4.2*0.0254; S0M=4.21*0.0254; L0=2.00*0.0254; | Reduced throat to control HF escaping | First Horn points up S1T=3.00*0.0254; S1M=40.0*0.0254; L1=120*0.0254; | Second Horn points down S2T=3.00*0.0254; S2M=25.0*0.0254; L2=95*0.0254;

So the upward pointing horn is 120 in long with a mouth of 40 in and downward is 95 inches long with a mouth of 25 inches. They both started with a 3 in throat fed by a common 4.2 in throat from a 3 liter driver volume chamber.

The sims are for 1 watt at 1 m and show freq response (red is long horn, green is short horn, black is combined with driver radiation), cone displacement, impedance, and impulse response. The impedance plots of double horns is very interesting - you can see the non-linear interactions of one horn with another. What is interesting is that lengthening the shorter horn decreases the frequency extension on long horn output - clearly showing an interaction of how this behaves like a double open ended resonator - which it is.

I did not have too much time to optimize for flat response - later...

Hi and a million thanks for doing a sim for this. I completely missed to include the depth of the styrofoam bits wich (at this point at least) are going to be 30 mm ie. 1.18". So three of them stacked is 90 mm and the horn has a depth of 30 mm. Sorry about that

Being a novice on horns I may have overestimated the boundary loading from wall + ceiling. Most of what I know Ive learned from reading Roy Allisons paper on speakers and room influence. I figured the wall + ceiling would be part of the horn giving a 6-9 dB of low end boost. If anyone can enlighten me on this. Please let me know 🙂

Regards /Bo

Danerius,

You are welcome. I wasn't very happy with the first simulation result as it requires such a long horn (10 ft!) and the impedance curve is a mess showing that there is a lot of horn-to-horn interaction going on. I decided to see what I could do to de-couple the two horns more to make the impedance and driver excursion plots behave better and reducing the horn lengths. It turns out that increasing the driver chamber volume is key as it provides the acoustic capacitance needed to de-couple the two horns thereby smoothing out the impedance and turning them into quarter-wave boundary conditions thus cutting lengths by about half.

The horn profile and chamber volumes are given here:

As you can seem the long horn length is now 60 inches (5 ft) and shorter horn is 42 in (about a meter) with an 18 in and 26 in mouth, respectively. I reduced the throats of the horns to 2.5 in and the common throat to 3 in with a 5 in duct connecting the driver chamber which has now been significantly increased to 14 liters in volume.

The depth of the chamber and horn is still kept at 90 mm (3.54 in). Your idea of making it only 30 mm is not good as the physical aperture size of the horn mouth determines the lowest frequencies that can get out. Making it 30 mm will reduce this and I believe the W5-1611 driver is 83 mm not leaving very much breathing room behind the driver even at 90 mm. I suggest using the three layers of 30 mm foam like you suggest but using all 3 for the horn and chamber and use thin 1/8 in or 1/4 in plywood for the back and baffle (face). The driver will mount better and it will look nicer. Be sure to use bracing ribs internal to the plywood every 3 or 4 inches to reduce the breathing mode vibrations in the horn.

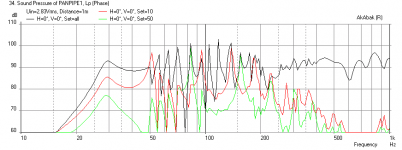

The results are as follows: freq response (black is total, red is long horn, green is short), cone displacement, impedance, impulse response, all for 1 watt at 1 meter.

You are welcome. I wasn't very happy with the first simulation result as it requires such a long horn (10 ft!) and the impedance curve is a mess showing that there is a lot of horn-to-horn interaction going on. I decided to see what I could do to de-couple the two horns more to make the impedance and driver excursion plots behave better and reducing the horn lengths. It turns out that increasing the driver chamber volume is key as it provides the acoustic capacitance needed to de-couple the two horns thereby smoothing out the impedance and turning them into quarter-wave boundary conditions thus cutting lengths by about half.

The horn profile and chamber volumes are given here:

Code:

Vol_ch = (14.0/1000) ; | Volume of driver chamber in liters

Depth_ch = (3.54*0.0254); | Depth of driver chamber

| Define Horn Segments (need to multiply by Depth for area): S_Throat, S_Mouth, Length

| Shared Throat Segment

S0T=3.0*0.0254; S0M=3.01*0.0254; L0=5.00*0.0254;

| First Horn points up

S1T=2.5*0.0254; S1M=18.0*0.0254; L1=60*0.0254;

| Second Horn points down

S2T=2.5*0.0254; S2M=26.0*0.0254; L2=42.0*0.0254;As you can seem the long horn length is now 60 inches (5 ft) and shorter horn is 42 in (about a meter) with an 18 in and 26 in mouth, respectively. I reduced the throats of the horns to 2.5 in and the common throat to 3 in with a 5 in duct connecting the driver chamber which has now been significantly increased to 14 liters in volume.

The depth of the chamber and horn is still kept at 90 mm (3.54 in). Your idea of making it only 30 mm is not good as the physical aperture size of the horn mouth determines the lowest frequencies that can get out. Making it 30 mm will reduce this and I believe the W5-1611 driver is 83 mm not leaving very much breathing room behind the driver even at 90 mm. I suggest using the three layers of 30 mm foam like you suggest but using all 3 for the horn and chamber and use thin 1/8 in or 1/4 in plywood for the back and baffle (face). The driver will mount better and it will look nicer. Be sure to use bracing ribs internal to the plywood every 3 or 4 inches to reduce the breathing mode vibrations in the horn.

The results are as follows: freq response (black is total, red is long horn, green is short), cone displacement, impedance, impulse response, all for 1 watt at 1 meter.

Attachments

A million thanks for takin ur time to do these sims 🙂 Few questions though? How accurate are the response charts? Are they with or without damping?

Is there a point to separating the different horns as much as possible? And is there an ideal ratio ie 1/3, 1/4 etc for the horn lenghts? Thats better to shoot for?

I adjusted the sketch for two ”isolated” horns. The chamber volume is not accurate at all

Regards /Bo

Is there a point to separating the different horns as much as possible? And is there an ideal ratio ie 1/3, 1/4 etc for the horn lenghts? Thats better to shoot for?

I adjusted the sketch for two ”isolated” horns. The chamber volume is not accurate at all

Regards /Bo

Danerius,

I don't know how accurate the response is as these are simulations. However, I have been able to confirm that many of my simulations using AkAbak of known systems that also have simulations using MJK's worksheets have provided similar results, albeit, the AkAbak doesn't have any damping effect modeled - so it will have sharp spikey peaks and dips which in all likelyhood will be smoothed out with stuffing. However, wider features in the frequency response curves will be real. The models I have presented only have a back and bottom wall so there is no reflection of the top wall horn - that may change things if it were considered. In your adjusted sketch of isolated horns, you lost some horn length due to chamber length taking up the horn length, and note that it is a different system than the previous one because the horns are now directly coupled to the driver chamber rather than sharing a common throat.

I don't know how accurate the response is as these are simulations. However, I have been able to confirm that many of my simulations using AkAbak of known systems that also have simulations using MJK's worksheets have provided similar results, albeit, the AkAbak doesn't have any damping effect modeled - so it will have sharp spikey peaks and dips which in all likelyhood will be smoothed out with stuffing. However, wider features in the frequency response curves will be real. The models I have presented only have a back and bottom wall so there is no reflection of the top wall horn - that may change things if it were considered. In your adjusted sketch of isolated horns, you lost some horn length due to chamber length taking up the horn length, and note that it is a different system than the previous one because the horns are now directly coupled to the driver chamber rather than sharing a common throat.

PBLH? (5 unequal length BLH)

I ran a sim with 5 or Penta BLH case with a long 12 ft path and each successive one was 0.9, 0.8, 0.7, 0.6 X the length of the longest one. The mouths were all 5x8 in in cross section, and the driver chamber was about 1100 cubic inch (18 liters). It worked out pretty smooth. It would be a complicated build with 5 horn channels but very smooth and gets 30 Hz bass extension. If anyone is interested I will post the sim and design.

I ran a sim with 5 or Penta BLH case with a long 12 ft path and each successive one was 0.9, 0.8, 0.7, 0.6 X the length of the longest one. The mouths were all 5x8 in in cross section, and the driver chamber was about 1100 cubic inch (18 liters). It worked out pretty smooth. It would be a complicated build with 5 horn channels but very smooth and gets 30 Hz bass extension. If anyone is interested I will post the sim and design.

Why only 90 mm depth? Are you planing to build in inside a plaster wall with cc 600mm beams?

Crabbe editor of HFN&RR in the 1960s built wall horns somewhat similar to your design using Lowther drivers and a short front horn as well. As I recall they were build flanking a mantle piece so the depth was probably in the order of 300 mm or so.

Crabbe editor of HFN&RR in the 1960s built wall horns somewhat similar to your design using Lowther drivers and a short front horn as well. As I recall they were build flanking a mantle piece so the depth was probably in the order of 300 mm or so.

Why only 90 mm depth? Are you planing to build in inside a plaster wall with cc 600mm beams?

Crabbe editor of HFN&RR in the 1960s built wall horns somewhat similar to your design using Lowther drivers and a short front horn as well. As I recall they were build flanking a mantle piece so the depth was probably in the order of 300 mm or so.

Hello dr Boar. The depth is for practical and aesthetic reasons. Its a relatively small room and I dont want two humongous speaker in it. The plan is for a thin one hanging on the wall making up for volume with width and height. Thought Id combine that with wall and floor boundary loading for the lowest bass

Any name for the Crabbe horn that I can google?

Regards /Bo

Edit: Plus the styrofoam sheets Im planning to use are 1200x600x30 mm. Hence the 600 mm choice for width and three of them stacked makes 90 mm depth 🙂

Last edited:

I ran a sim with 5 or Penta BLH case with a long 12 ft path and each successive one was 0.9, 0.8, 0.7, 0.6 X the length of the longest one. The mouths were all 5x8 in in cross section, and the driver chamber was about 1100 cubic inch (18 liters). It worked out pretty smooth. It would be a complicated build with 5 horn channels but very smooth and gets 30 Hz bass extension. If anyone is interested I will post the sim and design.

Cool. Id love to see that 🙂 Did u try it with three and four different length horns? Big difference in freq response from that and five?

Regards /Bo

Introducing the PANPIPE - a Penta Back Loaded Horn (PBLH)

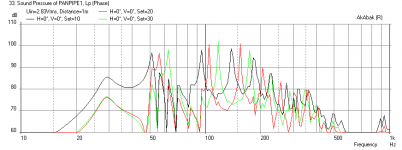

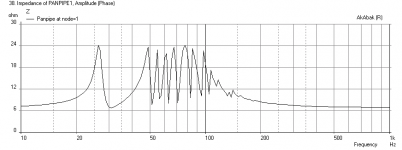

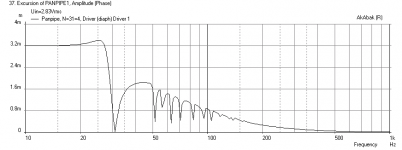

Here is the simulation of a 5 horn BLH with the horns front facing and stacked next to each other at the bottom of the cabinet. I have not worked out the full physical dimensions of the cabinet and what it would take to fold and route the passages yet. I am assuming the cabinet will be 25 in wide to accommodate qnty 5 x 5 in wide horns. The longest horn is 144 inches and each successive one is multiplied by 0.9, 0.8, 0.7, and 0.6 factors. Horns mouth 1 (longest) will be 12 in tall x 5 in wide, the rest are all 8 in high x 5 in wide. The throats for each horn were optimized and ended up as 2 in, 0.7 in, 0.7 in, 1.0 in, 0.7 in (times width of channel of 5 in). A common throat leading from driver chamber to plenum manifold of multiple throats is 4.0 in to 5.0 in x 5.0 in long (times width of channel of 5 in). The driver chamber is 18 liters. The driver is the W5-1611, and all calcs were for 1 watt input measured at 1 meter away. The first plot shows the horn output for 1, 2, and 3. The second plot is for horn output 3, 4, and 5. The third plot shows the total output of all horns combined with driver direct radiation (black, red is longest horn, green is shortest horn). As you can see, there are lots of resonance peaks for each horn but the spacing is evenly spread out as expected and the amplitudes are pretty well balanced. I imagine that with damping added to the driver chamber, and maybe a little in the common plenum section these peaks will all be blended into one smooth output. The fourth plot is the impedance, fifth plot is the driver cone displacement, and sixth is impulse response.

Any feedback on this design from folks would be appreciated. Is this just too much trouble to get a smooth horn output? I think the advantage will be that the sound from this speaker will have all the benefits of immediacy in deep bass response (the impulse response is relatively quick compared to a bass reflex or MLTL that will have significant delay). So the sound should be more natural. The 30 Hz bass extension is quite impressive with controlled cone motion just at the limit of the driver's range.

Here is the simulation of a 5 horn BLH with the horns front facing and stacked next to each other at the bottom of the cabinet. I have not worked out the full physical dimensions of the cabinet and what it would take to fold and route the passages yet. I am assuming the cabinet will be 25 in wide to accommodate qnty 5 x 5 in wide horns. The longest horn is 144 inches and each successive one is multiplied by 0.9, 0.8, 0.7, and 0.6 factors. Horns mouth 1 (longest) will be 12 in tall x 5 in wide, the rest are all 8 in high x 5 in wide. The throats for each horn were optimized and ended up as 2 in, 0.7 in, 0.7 in, 1.0 in, 0.7 in (times width of channel of 5 in). A common throat leading from driver chamber to plenum manifold of multiple throats is 4.0 in to 5.0 in x 5.0 in long (times width of channel of 5 in). The driver chamber is 18 liters. The driver is the W5-1611, and all calcs were for 1 watt input measured at 1 meter away. The first plot shows the horn output for 1, 2, and 3. The second plot is for horn output 3, 4, and 5. The third plot shows the total output of all horns combined with driver direct radiation (black, red is longest horn, green is shortest horn). As you can see, there are lots of resonance peaks for each horn but the spacing is evenly spread out as expected and the amplitudes are pretty well balanced. I imagine that with damping added to the driver chamber, and maybe a little in the common plenum section these peaks will all be blended into one smooth output. The fourth plot is the impedance, fifth plot is the driver cone displacement, and sixth is impulse response.

Any feedback on this design from folks would be appreciated. Is this just too much trouble to get a smooth horn output? I think the advantage will be that the sound from this speaker will have all the benefits of immediacy in deep bass response (the impulse response is relatively quick compared to a bass reflex or MLTL that will have significant delay). So the sound should be more natural. The 30 Hz bass extension is quite impressive with controlled cone motion just at the limit of the driver's range.

Attachments

-

Panpipe-W5-1611-P1-P2-P3-Freq.png25.9 KB · Views: 2,411

Panpipe-W5-1611-P1-P2-P3-Freq.png25.9 KB · Views: 2,411 -

Panpipe-W5-1611-P3-P4-P5-Freq.png25.5 KB · Views: 2,419

Panpipe-W5-1611-P3-P4-P5-Freq.png25.5 KB · Views: 2,419 -

Panpipe-W5-1611-ALL-P1-P5-Freq.png26.4 KB · Views: 3,501

Panpipe-W5-1611-ALL-P1-P5-Freq.png26.4 KB · Views: 3,501 -

Panpipe-W5-1611-Impedance.png19.6 KB · Views: 2,349

Panpipe-W5-1611-Impedance.png19.6 KB · Views: 2,349 -

Panpipe-W5-1611-Displ.png19.1 KB · Views: 2,361

Panpipe-W5-1611-Displ.png19.1 KB · Views: 2,361 -

Panpipe-W5-1611-Impulse.png12.7 KB · Views: 97

Panpipe-W5-1611-Impulse.png12.7 KB · Views: 97

Yes, it is feasible. I am working up build plans now. @Bcmbob said he will make it out of foam core in Foam Core thread.

Well, XRk he invited me to see this thread 🙂

But...a speaker attached to the wall ?

Styrofoam ??

No thx !

🙂 good luck!

But...a speaker attached to the wall ?

Styrofoam ??

No thx !

🙂 good luck!

Well, XRk he invited me to see this thread 🙂

But...a speaker attached to the wall ?

Styrofoam ??

No thx !

🙂 good luck!

Pico,

The Panpipe is not a wall mount - I just posted it here because at the time it was an extension of multiple horn BLH. It will be a conventional cabinet with horns facing forward located at bottom and driver at top. Approx 24 in wide x 48 in tall x 18 in deep. I think I need to start a new dedicated "Panpipe" thread.

X

Pico,

The Panpipe is not a wall mount - I just posted it here because at the time it was an extension of multiple horn BLH. It will be a conventional cabinet with horns facing forward located at bottom and driver at top. Approx 24 in wide x 48 in tall x 18 in deep. I think I need to start a new dedicated "Panpipe" thread.

X

I wish I had a bigger listening room...

Me too. The fact is that it's also my workshop,so...what a mess !

When I was to finish my latest ( test 🙂 ) speakers, some experience gained in the making made me revisioning the ones I had in use for one year.( just making the midtweeter suspended)

When I was to finish my latest ( test 🙂 ) speakers, some experience gained in the making made me revisioning the ones I had in use for one year.( just making the midtweeter suspended)

Well, XRk he invited me to see this thread 🙂

But...a speaker attached to the wall ?

Styrofoam ??

No thx !

🙂 good luck!

To each his own 🙂 My first BIBs were made with a set of no name, flea market, $3 a pair, 2" fullrangers in a styrofoam enclosure with absolutely no measurements or sims. Maybe I was incredibly lucky but they sounded great. In many ways more neutral than the much larger wooden BIBs with W5-1611s.

However. They were ugly as sin so they had to go. Thought Id try with a proper go at styrofoam again and see what it sounds like on a larger scale

Regards /Bo

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- DBLH