I received LM336z25 and LM336z5 from Mouser and breadboard Adcom j6 and LM336(2.5v) and found J6 is LM336z25(2.5v) indeed.

For my GFA 585's turn on and off thump (3v spike @ speaker terminal), new LM336 did not resolve the issue.

Across J6 and LM336z25 cathode and anode, there were brief "on & off" voltage spike upto 3.5v on my DMM which inturn caused 3v thump on scope on speaker terminals. As Anatech said, it might be perfectly normal to have this mild thumps.

I am done fiddling with my GFA585 amp for now. I am going to do some woodworking to build Audio Rack to house all my amps before my wife says about floor full of amps.

Thank you Chris and others!

For my GFA 585's turn on and off thump (3v spike @ speaker terminal), new LM336 did not resolve the issue.

Across J6 and LM336z25 cathode and anode, there were brief "on & off" voltage spike upto 3.5v on my DMM which inturn caused 3v thump on scope on speaker terminals. As Anatech said, it might be perfectly normal to have this mild thumps.

I am done fiddling with my GFA585 amp for now. I am going to do some woodworking to build Audio Rack to house all my amps before my wife says about floor full of amps.

Thank you Chris and others!

I am posting this to a very old thread, but hopefully someone will respond. Anatech seems to really know Adcoms!

I just got a GFA-565 that was reported to have a "hum". I have not yet powered it up.

I did open it, and have determined several things.

1) The control board shows no signs of any capacitor badness, but the caps do look as if they were replaced, so perhaps it was cleaned then, or perhaps the PO changed them preemptively. The caps look to be from several different series, not the light blue ones in the original amp. The solo 220 uf cap in the middle of the board was definitely replaced.

2) The big filter caps look OK, but they are original Adcom units. I suspect those are the cause of the hum. Does this make sense?

3) It looks like a transistor Q113 was replaced (the device is up off the PCB on longer leads). Is that a known fault area?

4) For some reason diodeD105 seems to have been replaced with a series connected set of THREE diodes. Any ideas what's up with that?

5) Strangely, several of the wires for the control board seem to have been spliced. The red/orange twisted pair that goes to the filter caps has a section that was replaced with a different pair of wires, and the white wire that goes from the middle of the board to the metal buss that connects the output stages has the same sort of splice.

6) There is a Yellow wire 19 that goes from the control board to output Pair 2. It has clearly been attached in a non factory way (just wrapped around the post and held with a nut, no soldered terminal like the other wires.

7) There appears to be some weird jury rigged pair of electrolytic caps in series with the output to Pair 1. The large white wire from the metal buss bar that connects the output stages has been added to. One goes to the Pair 2 output post (where is joint the yellow wire described above) and a newer slightly smaller gauge wire looks like it was added. It goes from that same metal buss to this pair of caps (probably back to back electrolytics trying to make an NP blocking cap). The other end of the capacitor is connected to output Pair 1. I suspect the amp had the usual DC offset issue, and some joker tried to fix it by putting in a series cap (AAAARGH!!!)

I am going to replace the big filter caps, remove the blocking cap kludge, and clean up the wiring. Then I'll fire it up and measure the offsets and such and see what else needs attention.

Any and all comments and advice are welcome.

Thanks

Scott

I just got a GFA-565 that was reported to have a "hum". I have not yet powered it up.

I did open it, and have determined several things.

1) The control board shows no signs of any capacitor badness, but the caps do look as if they were replaced, so perhaps it was cleaned then, or perhaps the PO changed them preemptively. The caps look to be from several different series, not the light blue ones in the original amp. The solo 220 uf cap in the middle of the board was definitely replaced.

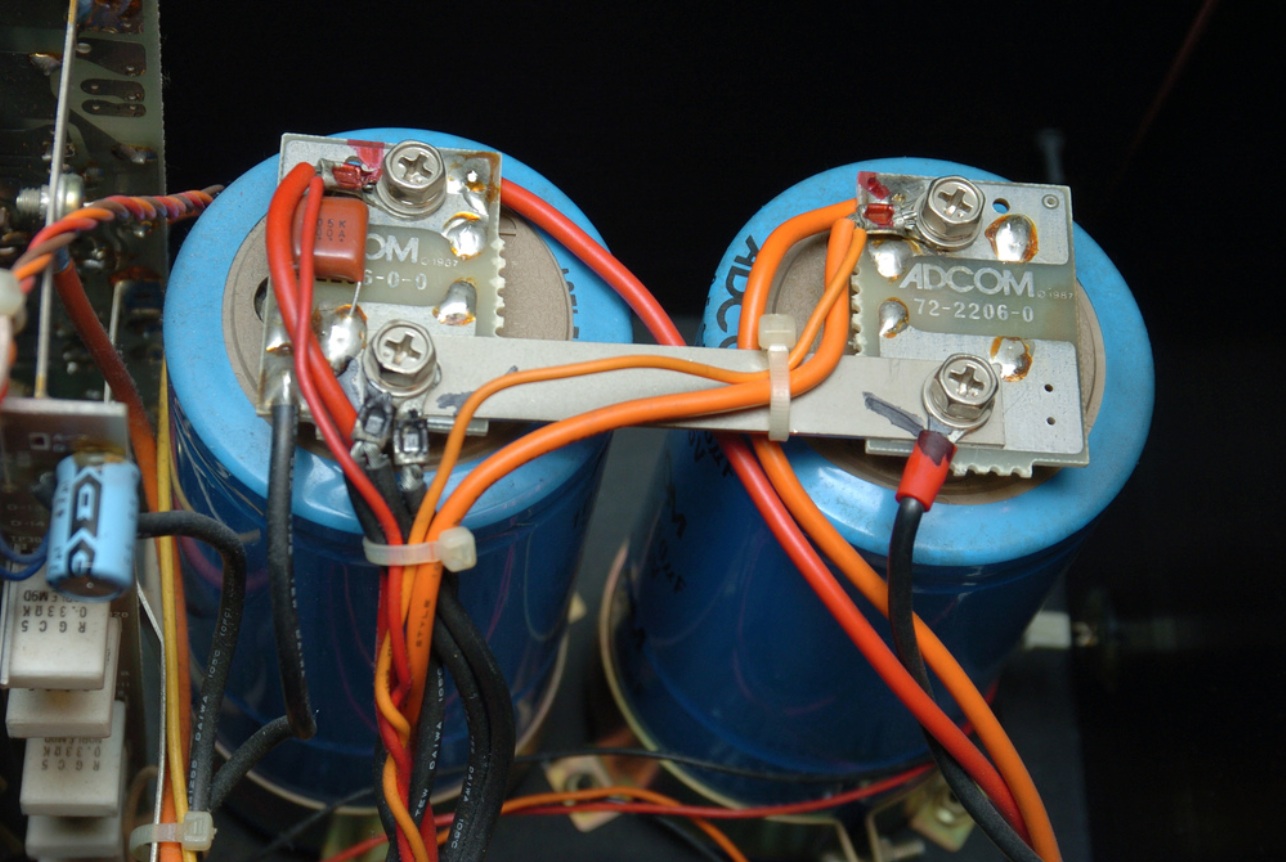

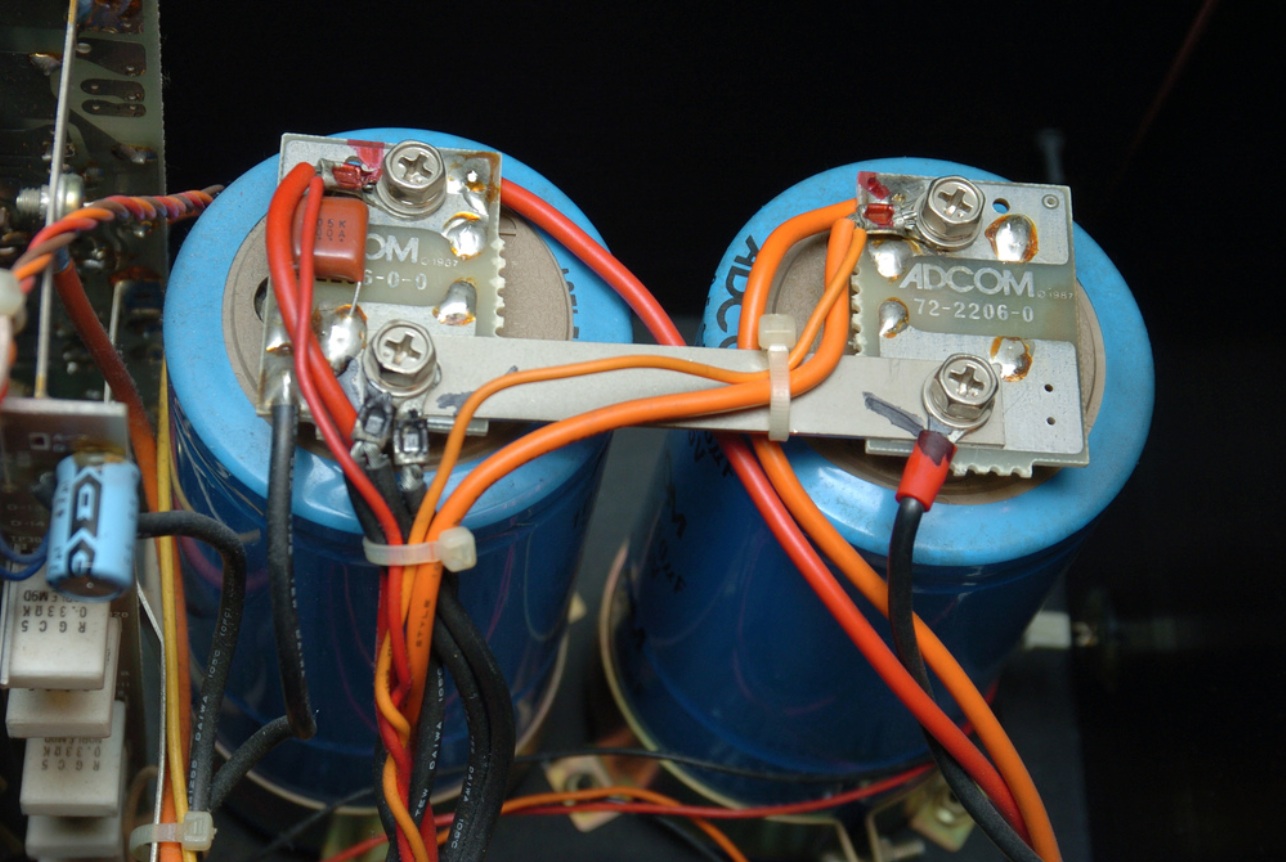

2) The big filter caps look OK, but they are original Adcom units. I suspect those are the cause of the hum. Does this make sense?

3) It looks like a transistor Q113 was replaced (the device is up off the PCB on longer leads). Is that a known fault area?

4) For some reason diodeD105 seems to have been replaced with a series connected set of THREE diodes. Any ideas what's up with that?

5) Strangely, several of the wires for the control board seem to have been spliced. The red/orange twisted pair that goes to the filter caps has a section that was replaced with a different pair of wires, and the white wire that goes from the middle of the board to the metal buss that connects the output stages has the same sort of splice.

6) There is a Yellow wire 19 that goes from the control board to output Pair 2. It has clearly been attached in a non factory way (just wrapped around the post and held with a nut, no soldered terminal like the other wires.

7) There appears to be some weird jury rigged pair of electrolytic caps in series with the output to Pair 1. The large white wire from the metal buss bar that connects the output stages has been added to. One goes to the Pair 2 output post (where is joint the yellow wire described above) and a newer slightly smaller gauge wire looks like it was added. It goes from that same metal buss to this pair of caps (probably back to back electrolytics trying to make an NP blocking cap). The other end of the capacitor is connected to output Pair 1. I suspect the amp had the usual DC offset issue, and some joker tried to fix it by putting in a series cap (AAAARGH!!!)

I am going to replace the big filter caps, remove the blocking cap kludge, and clean up the wiring. Then I'll fire it up and measure the offsets and such and see what else needs attention.

Any and all comments and advice are welcome.

Thanks

Scott

Hi Scott,

1./Check the control PCB by using a hot soldering iron to touch the PCB near the capacitor leads. The electrolyte is not something you can see. But the odor from the soldering iron will tell you definitively whether you have that problem or not.

2./No, they can cause hum, but normally the filter capacitors are fine. Check them first with an oscilloscope (AC coupling) to see the wave form. Post pictures please.

3./Nope. But someone is lazy.

4./The unit was serviced by an idiot. A cheap idiot. That is probably why the amplifier was sold in the first place.

5./Please correct all that sloppy wiring. Now we know for certain that the person who serviced this unit was a lazy, cheap idiot.

6./As above

7./I'll add stupid to the list of the attributes of the previous service person.

Seriously, unless you have a strong urge to lighten your wallet, wait on the main filter capacitors until you know for certain that you need new ones. If you are hearing a hum, the amp could be oscillating. If the filter capacitors were responsible for that, you would see massive ripple at 120 Hz on the guilty filter capacitor.

-Chris

1./Check the control PCB by using a hot soldering iron to touch the PCB near the capacitor leads. The electrolyte is not something you can see. But the odor from the soldering iron will tell you definitively whether you have that problem or not.

2./No, they can cause hum, but normally the filter capacitors are fine. Check them first with an oscilloscope (AC coupling) to see the wave form. Post pictures please.

3./Nope. But someone is lazy.

4./The unit was serviced by an idiot. A cheap idiot. That is probably why the amplifier was sold in the first place.

5./Please correct all that sloppy wiring. Now we know for certain that the person who serviced this unit was a lazy, cheap idiot.

6./As above

7./I'll add stupid to the list of the attributes of the previous service person.

Seriously, unless you have a strong urge to lighten your wallet, wait on the main filter capacitors until you know for certain that you need new ones. If you are hearing a hum, the amp could be oscillating. If the filter capacitors were responsible for that, you would see massive ripple at 120 Hz on the guilty filter capacitor.

-Chris

OK, good advice. Thanks!

I found a source online (adcomparts) that claims to sell the varistor, so I ordered it. Not sure how reliable they are.

Is there an alternate part number for that?

I'll do the electrolyte test tomorrow, and start cleaning up the wiring..even the soldering on the replacement stuff is terrible!

I'll post pics as I go.

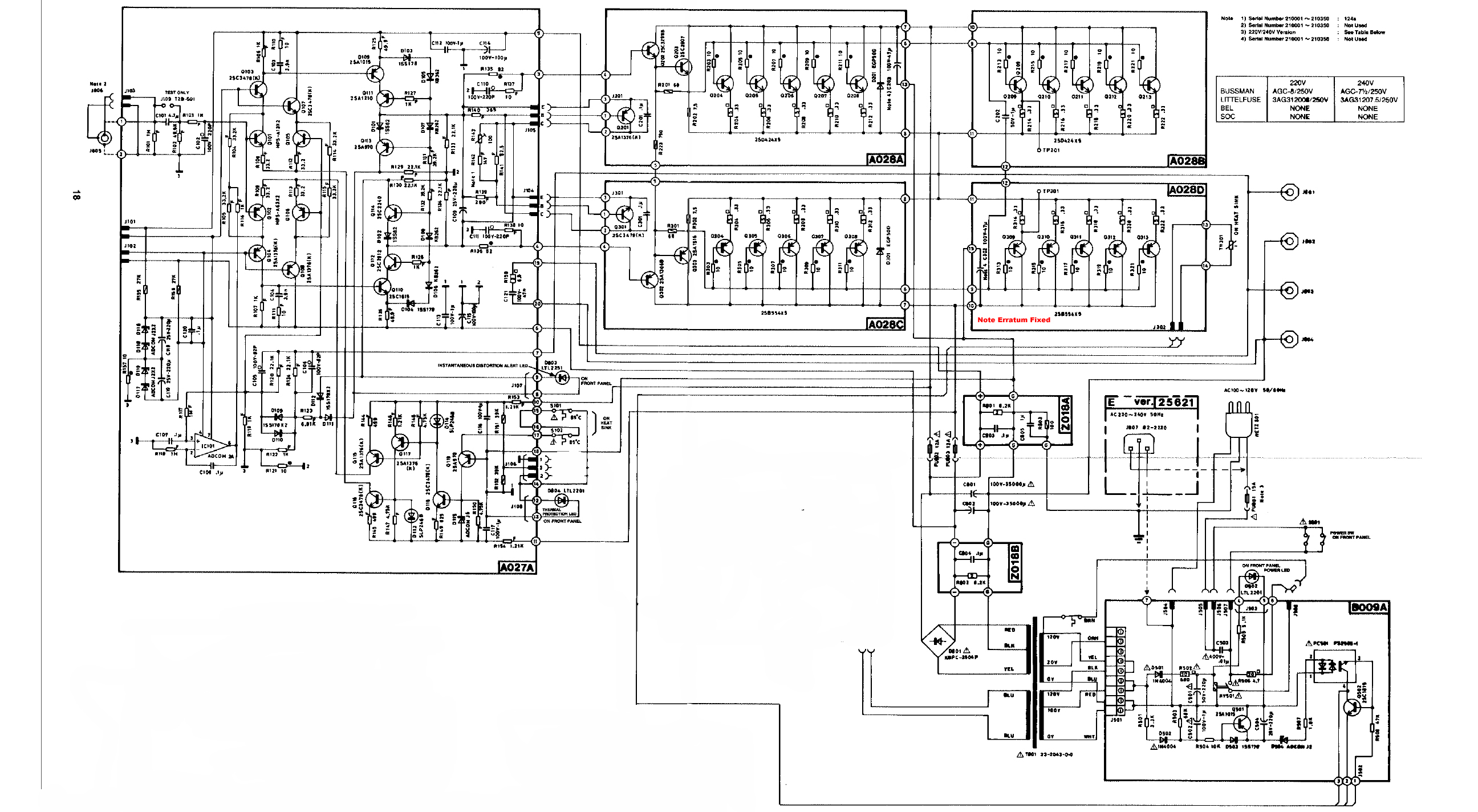

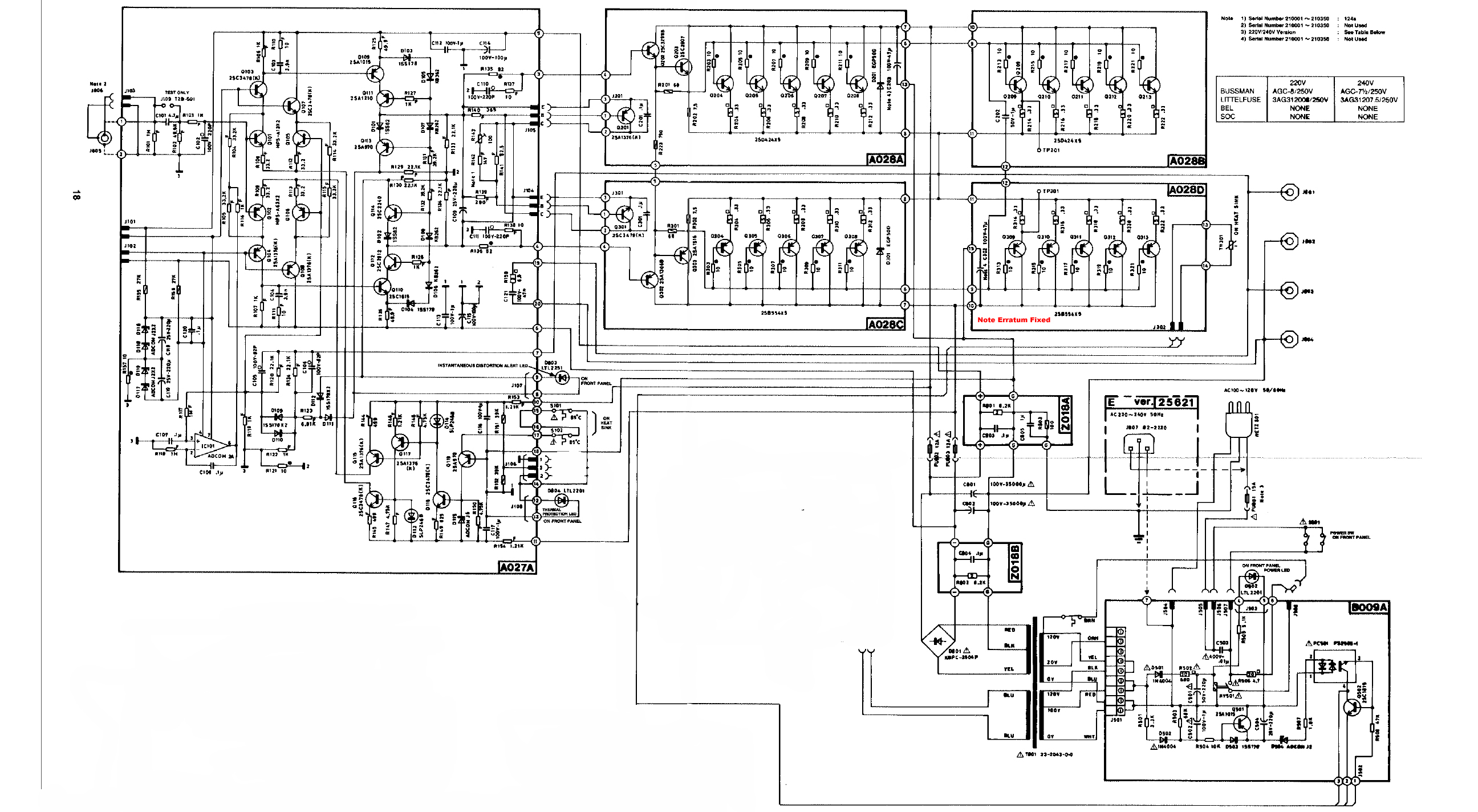

Also, for anyone who wants one, I joined up and corrected the GFA-565 schematic in the Service Manual, and corrected the erratum on the output signal line

I found a source online (adcomparts) that claims to sell the varistor, so I ordered it. Not sure how reliable they are.

Is there an alternate part number for that?

I'll do the electrolyte test tomorrow, and start cleaning up the wiring..even the soldering on the replacement stuff is terrible!

I'll post pics as I go.

Also, for anyone who wants one, I joined up and corrected the GFA-565 schematic in the Service Manual, and corrected the erratum on the output signal line

I noticed that in MJRs photo, and also on my amp, the 0.1 uF capacitors C803/804, and 8.2 K Ohm resistors R801/802 (the ones on the big filter cap boards) are missing. Is this a known improvement, or more work of the evil/stupid service tech?

The 1 uF/100 Ohm cap-resistor circuit is present on my system (and MJR's).

MJR's Photo:

The 1 uF/100 Ohm cap-resistor circuit is present on my system (and MJR's).

MJR's Photo:

I also have a question about the input architecture. Hopefully someone can provide a brief explanation (I am an EE, so I have a reasonable understanding of circuit design). I thought it would be a useful exercise, prior to powering up and diagnosing my amp, if I understood the basic circuitry. I can follow the output stages, but lose the concept when we get to the Q201/301 setup. and the mess of circuitry on the control board.

It looks like the input to the control board is a pair of differential pairs, but between there and the power output stages, there is a mess of signal and bias control circuitry. Can anyone explain how this works?

It looks like the input to the control board is a pair of differential pairs, but between there and the power output stages, there is a mess of signal and bias control circuitry. Can anyone explain how this works?

OK, so I fired up the amp today. It has some very odd behavior.

First, the DC on the big filter caps is about 85 volts, and rock solid. No ripple at all. So that's good..

The output offset ranges between near zero (about 0.06 to 0.15 volts) MOST of the time. However, at times it jumps to about -2.5 volts.

I checked the voltage across the test points on the output boards, and it is ZERO. Not sure what's up with that...

I decided to put a low voltage 1KHz signal across the input. I got about a 2 volt sinusoid on the output (I didn't want to turn it up too high). So that seemed to be OK.

As I was testing it this way, the DC offset was at its low state (0.06 to 0.15 volts). However, suddenly the output sinusoid started clipping in both directions (positive and negative) at about +/-2 volts, and I noticed that in this state the DC offset was again about -2 volts.

Probing further, I checked the input to the output stages (points 3 and 4 on the control board. These are OK, but there does not appear to be any gain between the inout and these points

The output state change seems somewhat random. It will sit for a long time in one state, and then jump to the other, and either jump back, or hang there for a while.

I think the best thing to do is to remove the control board, clean it, for good measure, and check all of the components, including replacing the ones kluged-in by the PO. For example the zener diode pairs D116/D118, and D117/D119 have each been replaced by a single diode of unknown type. As noted in my earlier post, at least one varistor has been replaced by a string of diodes..Plus the soldering and wiring looks like crap..

What sort of I/O gain should I be expecting between the input and the outputs (points 3 and 4) of the board?

First, the DC on the big filter caps is about 85 volts, and rock solid. No ripple at all. So that's good..

The output offset ranges between near zero (about 0.06 to 0.15 volts) MOST of the time. However, at times it jumps to about -2.5 volts.

I checked the voltage across the test points on the output boards, and it is ZERO. Not sure what's up with that...

I decided to put a low voltage 1KHz signal across the input. I got about a 2 volt sinusoid on the output (I didn't want to turn it up too high). So that seemed to be OK.

As I was testing it this way, the DC offset was at its low state (0.06 to 0.15 volts). However, suddenly the output sinusoid started clipping in both directions (positive and negative) at about +/-2 volts, and I noticed that in this state the DC offset was again about -2 volts.

Probing further, I checked the input to the output stages (points 3 and 4 on the control board. These are OK, but there does not appear to be any gain between the inout and these points

The output state change seems somewhat random. It will sit for a long time in one state, and then jump to the other, and either jump back, or hang there for a while.

I think the best thing to do is to remove the control board, clean it, for good measure, and check all of the components, including replacing the ones kluged-in by the PO. For example the zener diode pairs D116/D118, and D117/D119 have each been replaced by a single diode of unknown type. As noted in my earlier post, at least one varistor has been replaced by a string of diodes..Plus the soldering and wiring looks like crap..

What sort of I/O gain should I be expecting between the input and the outputs (points 3 and 4) of the board?

Hi Scott,

Too many questions for the time I have. Here goes some.

The gain should be around 30 dB, plus or minus a couple. The main thing is that you should have approximately that amount of gain.

Before going any further, replace the crap and clean up the work. This may resolve some of your issues. I think the four zener diodes are actually 7.5 V references, very low noise devices. LM329 maybe. Check the data sheet for what they are.

Your loss of gain can be an open feedback resistor to ground. It looks like 1K0 in your diagram.

Clean everything up and stick the LM 329's back in the circuit and check it again.

-Chris

Too many questions for the time I have. Here goes some.

The gain should be around 30 dB, plus or minus a couple. The main thing is that you should have approximately that amount of gain.

Before going any further, replace the crap and clean up the work. This may resolve some of your issues. I think the four zener diodes are actually 7.5 V references, very low noise devices. LM329 maybe. Check the data sheet for what they are.

Your loss of gain can be an open feedback resistor to ground. It looks like 1K0 in your diagram.

Clean everything up and stick the LM 329's back in the circuit and check it again.

-Chris

Thanks Chris;

I just ordered a set of parts: Zeners, caps, and various transistors (just in so I have them), and will start reworking the board soon. Based on what I have seen, the PO was indeed a moron, with no real concern for using the correct parts...

Do you have any thoughts on how to match the MPS-A13 and A63 transistors? The service manual says they are matched pairs. Do I set up a little breadboard to bias them and then check current? They were pretty cheap, so I bought 10 of each.. Hopefully the are not bad, but who knows!

On closer examination, There seem to be two odd resistor networks in place where R127 and R128 were. It is a 68K resistor between the wiper and one end of a 100K ohm pot, and a 1K resistor between the wiper and the other end. The two ends of the pot are connected where R127 or R128 go. . I assume this was some sort of bias adjustment, but it goes between 980 ohms and 38K ohms, which is a pretty huge adjustment range...given that this contraption replaced a 1% 1K resistor.. I would think if you wanted to make that adjustable around 1K you would use 900 and 1100 ohm resistors bridged by a 100K pot. These were adjusted about mid range, so that would put R127 and 128 at about 30K, so this could be the source of the gain issue.. I noticed the waveform was really distorted at some places on the board, and mucking around with the operating point on the transistors would probably have that effect.

Cheers,

Scott

I just ordered a set of parts: Zeners, caps, and various transistors (just in so I have them), and will start reworking the board soon. Based on what I have seen, the PO was indeed a moron, with no real concern for using the correct parts...

Do you have any thoughts on how to match the MPS-A13 and A63 transistors? The service manual says they are matched pairs. Do I set up a little breadboard to bias them and then check current? They were pretty cheap, so I bought 10 of each.. Hopefully the are not bad, but who knows!

On closer examination, There seem to be two odd resistor networks in place where R127 and R128 were. It is a 68K resistor between the wiper and one end of a 100K ohm pot, and a 1K resistor between the wiper and the other end. The two ends of the pot are connected where R127 or R128 go. . I assume this was some sort of bias adjustment, but it goes between 980 ohms and 38K ohms, which is a pretty huge adjustment range...given that this contraption replaced a 1% 1K resistor.. I would think if you wanted to make that adjustable around 1K you would use 900 and 1100 ohm resistors bridged by a 100K pot. These were adjusted about mid range, so that would put R127 and 128 at about 30K, so this could be the source of the gain issue.. I noticed the waveform was really distorted at some places on the board, and mucking around with the operating point on the transistors would probably have that effect.

Cheers,

Scott

Hi Scott,

Make it like the paperwork you have (the manual).

Matching those transistors is not fun. I made a jig and tested the transistors for balance at the tail current the circuit uses. The jig was simply a differential pair using the match hopefuls. When your voltages on the two collectors match, the transistors are matched. It is very sensitive to temperature and air currents.

-Chris

Make it like the paperwork you have (the manual).

Matching those transistors is not fun. I made a jig and tested the transistors for balance at the tail current the circuit uses. The jig was simply a differential pair using the match hopefuls. When your voltages on the two collectors match, the transistors are matched. It is very sensitive to temperature and air currents.

-Chris

Hi Scott,

Make it like the paperwork you have (the manual).

Matching those transistors is not fun. I made a jig and tested the transistors for balance at the tail current the circuit uses. The jig was simply a differential pair using the match hopefuls. When your voltages on the two collectors match, the transistors are matched. It is very sensitive to temperature and air currents.

-Chris

So, I assume that involves an appropriate polarity current source, and some base bias voltage, right? What are the specs on those? Is the Vbe just fixed by grounding the bases and letting the current source pull the emitters down to draw the appropriate tail current? What was the collector load resistance?

Scott

Worked out a very clean low noise current source setup using a zero drift LT opamp with a current buffer. I can set the current with a resistor and use that to match the transistors.

I figure with 10 candidates, I have 45 possible pairs...so hopefully I can find a matching pair!

I figure with 10 candidates, I have 45 possible pairs...so hopefully I can find a matching pair!

Hi cogeniac. Good luck on your work on the 565. Earlier last summer, i also refurbished a pair or 565 (successfully) that had massive DC offset when the amps were being powered off. Fortunately, only a through ultrasonic cleaning needed to be done in order to bring the amps back to life. There were no bad parts in them, but i replaced all the input boards caps again (they had already been replaced) with new Panasonic FC series 105c caps.

Earlier this month, I bought a non working 585 on ebay, and found out that it had been subject to a botched repair attempt. One of the right channel's 2SB554 was previously removed, and was replaced with a B697 transistor. On the left channel input board, R210 and R118 (49.9 ohm 1/4w 1%) were badly burned, though still testing good, and within tolerance. I replaced these. I also had to replace R116 and R136 (both 10 ohm 1/4w 1% fusible resistor) which were out of tolerance (one was 15 ohms, and the other 13 ohms). I will have to find a way to test the matching pairs (MPS-A13 and MPS-A63) transistors, as they have an hfe too high for my DMM to measure properly. Power resistor R506 was replaced with a 2.7 ohms 25w.... Bleed resistors R801 and R802 8.2k 2w were removed, as well as C803, C804 and C805, and not reinstalled..... One of the 10A + rail fuse was replaced by a different 10A fuse, so i know that this fuse blew before. Fortunately, both channels input boards are in good condition, not corroded, but they were covered with a yellow kind of sticky goo, that looked like a dried liquid of some sort (possibly orange juice or coffee) was accidently poured inside the amp. The bottom inside of the amp is covered with this sticky goo.

First thing i did when i received the amp, I removed the top cover, and when i saw the mess, decided not to power on the amp, to test it, but proceeded to unsolder the wires, and remove the boards, instead, and clean them thoroughly with my ultrasonic cleaner and simple green. I have ordered a bunch of parts, but i'm pretty sure i will succeed with the refurbishing process. So when i get the parts, i will remove the heat sinks from the amp, and measure each and every output transistors. I will try to source some of the 2SB554 and 2SD424 transistors, in case some of them could be blown. Does anyone know if these are difficult to find, and also if they will be difficult to match with the remaining four, as i plan to replace the B697 transistor, and put a 2SB554 back in (at this point, i'm assuming the remaining four 2SB554 are still good)?

Another area of the amp that i will have to look into is Q108, that exhibits a curious behavior when measured. I dont know if this odd measuring is due to diode D121 being in parallel with the base and emitter of Q108, but there is continuity there, possibly a short. I will have to unsolder the transistor, so that i can test it separetely. The rest of the parts seem to be testing OK. So i have many hours of troubleshooting ahead, when i get the parts that i've ordered. 😱) I'll keep you guys posted. Will try to take pictures along the way, but don't know how to post them here.

Earlier this month, I bought a non working 585 on ebay, and found out that it had been subject to a botched repair attempt. One of the right channel's 2SB554 was previously removed, and was replaced with a B697 transistor. On the left channel input board, R210 and R118 (49.9 ohm 1/4w 1%) were badly burned, though still testing good, and within tolerance. I replaced these. I also had to replace R116 and R136 (both 10 ohm 1/4w 1% fusible resistor) which were out of tolerance (one was 15 ohms, and the other 13 ohms). I will have to find a way to test the matching pairs (MPS-A13 and MPS-A63) transistors, as they have an hfe too high for my DMM to measure properly. Power resistor R506 was replaced with a 2.7 ohms 25w.... Bleed resistors R801 and R802 8.2k 2w were removed, as well as C803, C804 and C805, and not reinstalled..... One of the 10A + rail fuse was replaced by a different 10A fuse, so i know that this fuse blew before. Fortunately, both channels input boards are in good condition, not corroded, but they were covered with a yellow kind of sticky goo, that looked like a dried liquid of some sort (possibly orange juice or coffee) was accidently poured inside the amp. The bottom inside of the amp is covered with this sticky goo.

First thing i did when i received the amp, I removed the top cover, and when i saw the mess, decided not to power on the amp, to test it, but proceeded to unsolder the wires, and remove the boards, instead, and clean them thoroughly with my ultrasonic cleaner and simple green. I have ordered a bunch of parts, but i'm pretty sure i will succeed with the refurbishing process. So when i get the parts, i will remove the heat sinks from the amp, and measure each and every output transistors. I will try to source some of the 2SB554 and 2SD424 transistors, in case some of them could be blown. Does anyone know if these are difficult to find, and also if they will be difficult to match with the remaining four, as i plan to replace the B697 transistor, and put a 2SB554 back in (at this point, i'm assuming the remaining four 2SB554 are still good)?

Another area of the amp that i will have to look into is Q108, that exhibits a curious behavior when measured. I dont know if this odd measuring is due to diode D121 being in parallel with the base and emitter of Q108, but there is continuity there, possibly a short. I will have to unsolder the transistor, so that i can test it separetely. The rest of the parts seem to be testing OK. So i have many hours of troubleshooting ahead, when i get the parts that i've ordered. 😱) I'll keep you guys posted. Will try to take pictures along the way, but don't know how to post them here.

Last edited:

Hi ypelchat,

With amplifiers, test back until you start finding good devices. Replace one level back from the last bad part and forward to the outputs. They are all garbage, don't bother testing them because even if they test good, they were run past their ratings and often fail later on.

Watch for an odd smell when you are soldering around the electrolytic capacitors. If you smell this, you need to remove all the electrolytic caps, then everything around them, including the op amp and voltage regulators (looks like TO-92 transistors near the PCB edges). You're going to have to clean the PCB and all the parts. This stuff isn't visible and can soak into the PCB material. One took me a few years to get clean to the point where the problems were gone. Nasty stuff. If you see the legs rotted off a part, that section was hit really badly.

-Chris

With amplifiers, test back until you start finding good devices. Replace one level back from the last bad part and forward to the outputs. They are all garbage, don't bother testing them because even if they test good, they were run past their ratings and often fail later on.

Watch for an odd smell when you are soldering around the electrolytic capacitors. If you smell this, you need to remove all the electrolytic caps, then everything around them, including the op amp and voltage regulators (looks like TO-92 transistors near the PCB edges). You're going to have to clean the PCB and all the parts. This stuff isn't visible and can soak into the PCB material. One took me a few years to get clean to the point where the problems were gone. Nasty stuff. If you see the legs rotted off a part, that section was hit really badly.

-Chris

Hi ypelchat,

With amplifiers, test back until you start finding good devices. Replace one level back from the last bad part and forward to the outputs. They are all garbage, don't bother testing them because even if they test good, they were run past their ratings and often fail later on.

Watch for an odd smell when you are soldering around the electrolytic capacitors. If you smell this, you need to remove all the electrolytic caps, then everything around them, including the op amp and voltage regulators (looks like TO-92 transistors near the PCB edges). You're going to have to clean the PCB and all the parts. This stuff isn't visible and can soak into the PCB material. One took me a few years to get clean to the point where the problems were gone. Nasty stuff. If you see the legs rotted off a part, that section was hit really badly.

-Chris

Yup! That's what i did. Before the ultrasonic bath, i've removed the electrolytic capacitors, the OP amp and the pre-driver transistors

(the two located near the two pc board LED's). It seems to me that the damage to this amp was done because of the mysterious liquid spilled inside the amp. I've gained a lot of experience with the two 565. I have a question though. Can you confirm that there is an 8.2k resistor across each of the four main power supply electrolytic capacitors? I see four 8.2k resistors on the schematics, R801, R802, R802 and R802 again!! I find it odd that ADCOM chose to list R802 multiple times.. Same thing for C803 and C804.

I have another question regarding the ADCOM J6 zener??? The LM336 seems to come in a 2.49v version AND in a 2.5v version. Do you know which one to use (just asking in the event that i might have to order a replacement) I already have the ADCOM J2 (LM329) on order.

Anyway, i'll take my time doing the overhaul, to make sure i do this right. I was so pleased by the GFA-565 performance, after the overhaul, that i had decided to try to do the same with a GFA-585. Now, If only i could find a way to post pics here, you would see the big difference between the boards, before the bath, and after. The boards now look like new boards!!! Thanks! 🙂

Last edited:

I have another question regarding the GFA-585/GFA-565 transistors. I found that most of the 565/585 transistors can be found on eBay, but i'm wondering if these transistors really are genuine. For example, the 2SB554 and 2SD424 output transistors for sale on eBay, are advertised as genuine Toshiba parts, but i'm not sure that Toshiba still make them. These transistors might be counterfeit IMHO. Don't know either if ADCOM still has them in stock.

I also found the MPS-A13 and MPS-A63. Two versions of these transistors seem to exist, a 600mA version, and a 1.2A version. Anyone know the version used in the GFA-565/585??

I also found the MPS-A13 and MPS-A63. Two versions of these transistors seem to exist, a 600mA version, and a 1.2A version. Anyone know the version used in the GFA-565/585??

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Damaged Adcom 565 Monoamps