A friend mine recently obtained a Tek 570 tracer. It's bit rough looking but should be salvageable.

Wow, those are really hard to find now. I think I saw one back in 1975 at a surplus store in Kingston NY, P&D Surplus. I don't recall the price, All tubes inside.

TekWiki: https://w140.com/tekwiki/wiki/570

https://w140.com/tekwiki/images/3/3c/Tektronix-570-Outside-Front.jpg

https://w140.com/tekwiki/wiki/570#/media/File:Tektronix-570-Inside-Right.jpg

https://w140.com/tekwiki/wiki/570#/media/File:Tektronix-570-Inside-Left.jpg

Looks like it has up to 10V per step and up to 12 steps. Plate sweep up to 500V at 0.25A avg. and 1 A pk . I don't see any provision to do positive steps for the screen grid, but it does have a regulated screen supply, I guess one could rotate the knob for that to get some feel for g2 curves.

It weighs 75 Lbs too, look at those BIG xfmrs in it. 300 to 500 Watts from the line. (the 576 says 305 Watts from line and weighs 75 Lbs too)

Hopefully your friend can get a manual, if they don't already have one. I wonder if there are any repair websites or You Tube videos for it.

TekWiki: https://w140.com/tekwiki/wiki/570

https://w140.com/tekwiki/images/3/3c/Tektronix-570-Outside-Front.jpg

https://w140.com/tekwiki/wiki/570#/media/File:Tektronix-570-Inside-Right.jpg

https://w140.com/tekwiki/wiki/570#/media/File:Tektronix-570-Inside-Left.jpg

Looks like it has up to 10V per step and up to 12 steps. Plate sweep up to 500V at 0.25A avg. and 1 A pk . I don't see any provision to do positive steps for the screen grid, but it does have a regulated screen supply, I guess one could rotate the knob for that to get some feel for g2 curves.

It weighs 75 Lbs too, look at those BIG xfmrs in it. 300 to 500 Watts from the line. (the 576 says 305 Watts from line and weighs 75 Lbs too)

Hopefully your friend can get a manual, if they don't already have one. I wonder if there are any repair websites or You Tube videos for it.

Last edited:

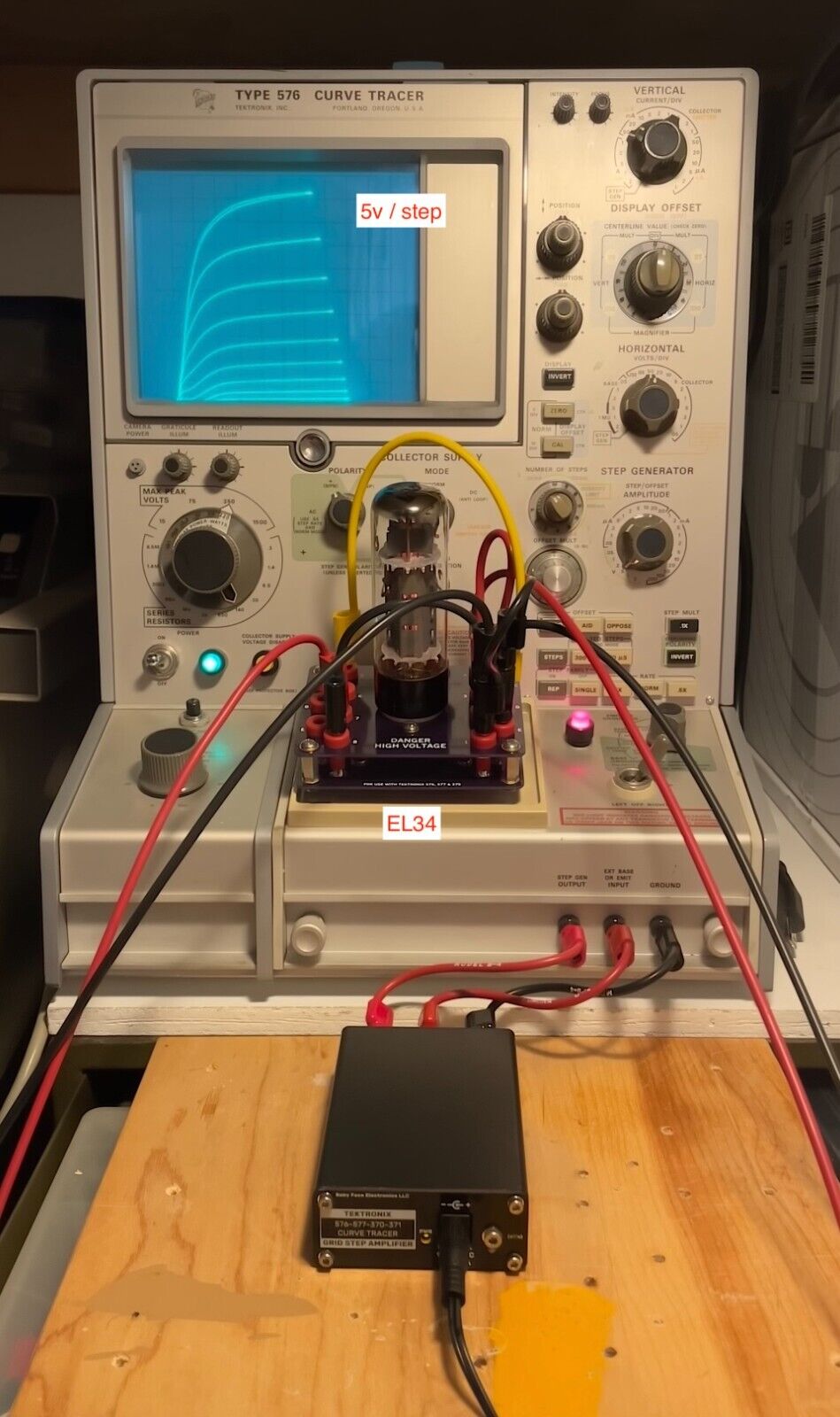

Since I have a 2nd working Tek 576 now (bought for spare parts), but without my mods yet for extended grid stepping V range,

I bought one of these new Tek 576 Grid Step Amplifier 10X modules to try out (Ebay pics 1 & 2):

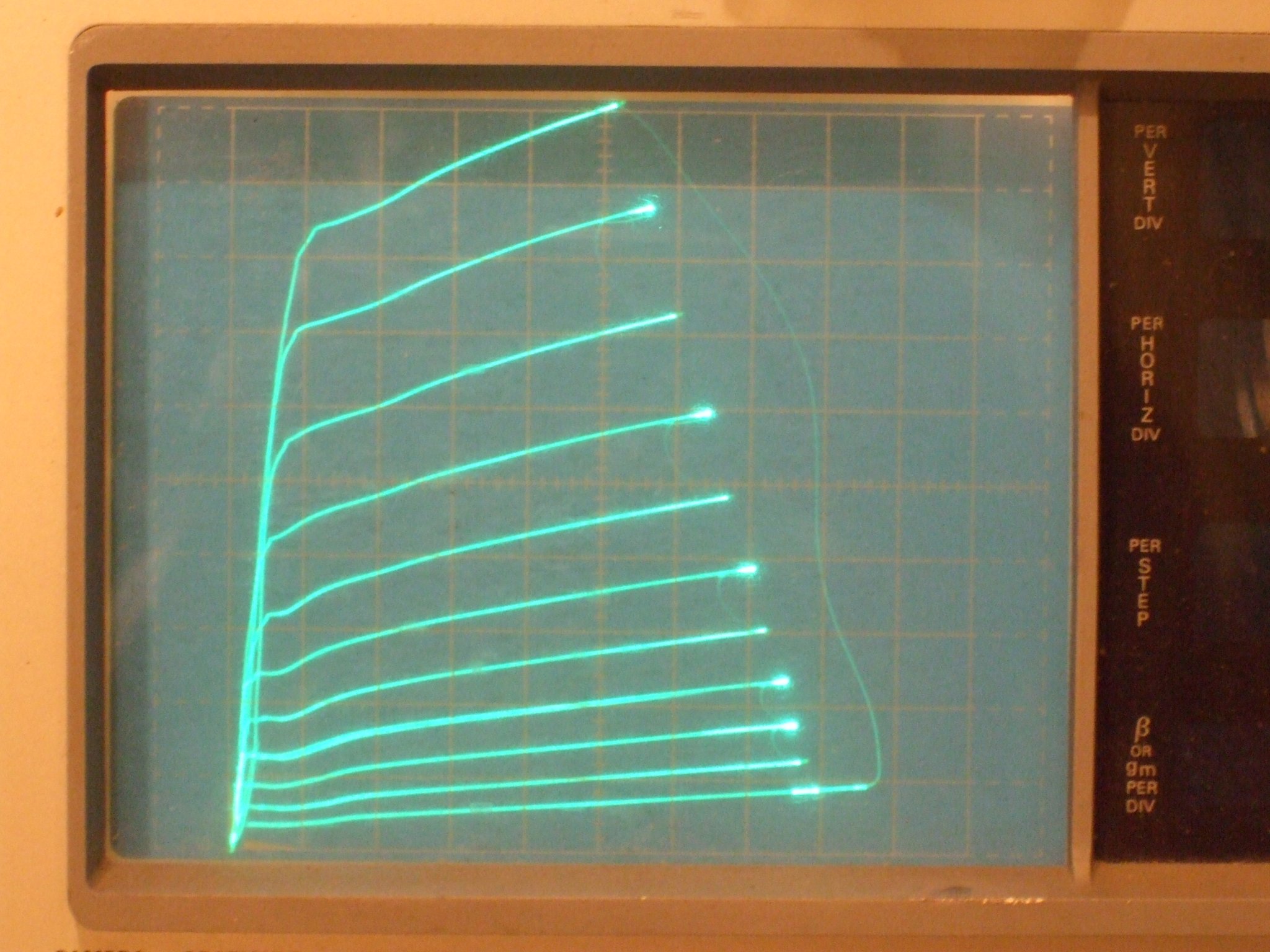

And it works! (3rd & 4th pics of a 10JA5 curve trace here) So it's a simple way to convert a Tek 576 to tube tracing.

However, I would still recommend making a couple of simple mods to the 576. (mods used in the full mod version too) The Screen V needs to turn off when you stop curve tracing a tube. You can do that manually all the time, but eventually you'll forget and take out a tube! This just requires some re-wiring of the DUT toggle switch in the bottom test box (it plugs into the 576, so easy to get to). I used one of the switch contacts, normally used for switching a sense line, to apply screen V when tracing either tube position. We're not testing high current SS here, so it is not needed for tube current wire loss. (it's still re-configurable for high current SS from the exterior front panel via some Banana jacks I installed)

I actually just pulled the box from the other 576 for a quick testing session tonight.

The other issue I see is the lack of a continuous stepping V gain control. You are stuck with the 1, 2, 5, 10... gain sequence from the step control knob on the front panel. Often the curve set will not fill the full screen that way, or runs off the edge. This mod is easy to do also. You just wire a potentiometer in series with the Step Amplifier global N Fdbk resistor to allow a continuous 10 to 1 gain control range. (well I used 10 to 1 for the full mod to extend the range, but 2 to 1 would work fine for the Grid Step Amplifier.)

An alternative mod would be to just put in the mod for 15 steps (from the normal 10). The # of steps is selectable up front, so this is just like a 1 to 1.5 adjustable gain range. Just requires pulling one pin on an IC in the step generator and changing a resistor in the D/A circuit. You'll be happy with the results in any case.

I bought one of these new Tek 576 Grid Step Amplifier 10X modules to try out (Ebay pics 1 & 2):

And it works! (3rd & 4th pics of a 10JA5 curve trace here) So it's a simple way to convert a Tek 576 to tube tracing.

However, I would still recommend making a couple of simple mods to the 576. (mods used in the full mod version too) The Screen V needs to turn off when you stop curve tracing a tube. You can do that manually all the time, but eventually you'll forget and take out a tube! This just requires some re-wiring of the DUT toggle switch in the bottom test box (it plugs into the 576, so easy to get to). I used one of the switch contacts, normally used for switching a sense line, to apply screen V when tracing either tube position. We're not testing high current SS here, so it is not needed for tube current wire loss. (it's still re-configurable for high current SS from the exterior front panel via some Banana jacks I installed)

I actually just pulled the box from the other 576 for a quick testing session tonight.

The other issue I see is the lack of a continuous stepping V gain control. You are stuck with the 1, 2, 5, 10... gain sequence from the step control knob on the front panel. Often the curve set will not fill the full screen that way, or runs off the edge. This mod is easy to do also. You just wire a potentiometer in series with the Step Amplifier global N Fdbk resistor to allow a continuous 10 to 1 gain control range. (well I used 10 to 1 for the full mod to extend the range, but 2 to 1 would work fine for the Grid Step Amplifier.)

An alternative mod would be to just put in the mod for 15 steps (from the normal 10). The # of steps is selectable up front, so this is just like a 1 to 1.5 adjustable gain range. Just requires pulling one pin on an IC in the step generator and changing a resistor in the D/A circuit. You'll be happy with the results in any case.

Last edited:

I forgot to mention that it only takes 1 of the new Grid Step Amplifier 10X modules to test either of two tubes in the 576 test fixture. That's because of the way Tek did the external interface option Banana plugs, the amplifier gets inserted -before- the tube selector Toggle switch. Very nice. The ability to toggle between two tubes is essential for matching tubes. I wasn't even aware of the External Step Option until this 10X module came along. Tek seems to have thought of almost everything when they designed the 576.

By the way, I peaked under the hood, and the new 10X module is using Analog Devices new 200+ V Op Amp, the ADHV702. There is an evaluation board for it available if you need a +/- 100V Op Amp. (Digi-Key and other suppliers have them) Has incredible specs.

I do plan to do my -full- tube upgrade mods on this later Tek 576 unit (which was originally just for spare parts, until I found it worked just fine! ). So the 10X Grid Step Amplifier won't be strictly needed then. But I have plans for the module yet. I will add an -inverted- phase low level Step Gen output BNC conn. that this 10X module can connect to, for a Complementary Stepper output. This will allow testing 2 tubes simultaneously in Push-Pull configuration. A DC current probe can then subtract the plate currents for display on a separate scope display. (An OT gets added for connecting the two plates to the swept Plate/Collector test terminal.) This will provide a graphic display of the resultant P-P summed currents usually shown in text books with a flipped around set of plate curves and regular plate curves offset by biasing. Biasing, Screen V, and Plate V can then be optimized for best P-P operation.

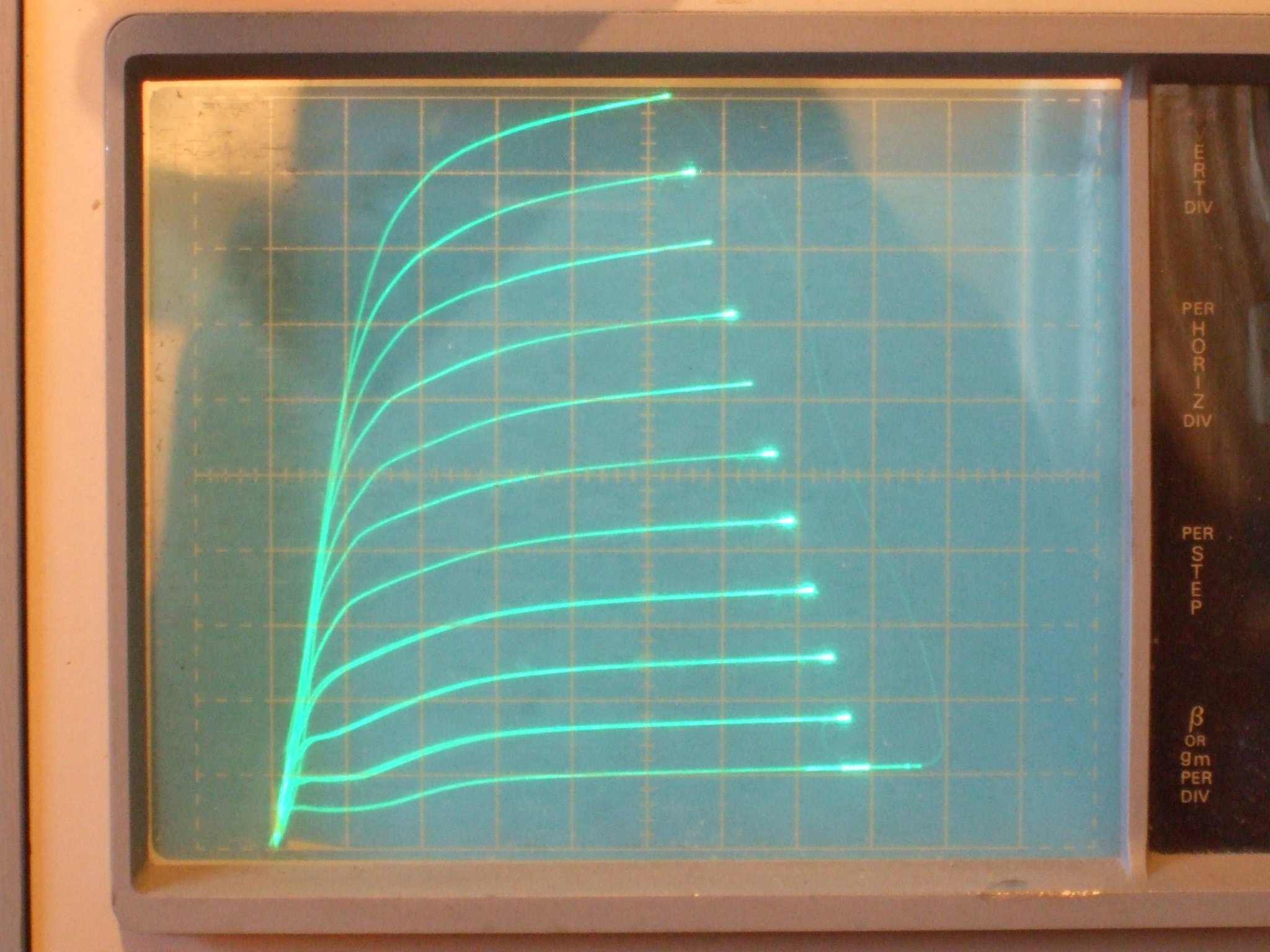

But until then, its already working as a good 2nd tube curve tracer. Here is the JJ KT77 tube, curve traced using the 10X Grid Step Module on the second 576:

Very nice curves. Look how evenly spaced. You won't be seeing any significant 3rd harmonic in a P-P amplifier with these tubes.

By the way, I peaked under the hood, and the new 10X module is using Analog Devices new 200+ V Op Amp, the ADHV702. There is an evaluation board for it available if you need a +/- 100V Op Amp. (Digi-Key and other suppliers have them) Has incredible specs.

I do plan to do my -full- tube upgrade mods on this later Tek 576 unit (which was originally just for spare parts, until I found it worked just fine! ). So the 10X Grid Step Amplifier won't be strictly needed then. But I have plans for the module yet. I will add an -inverted- phase low level Step Gen output BNC conn. that this 10X module can connect to, for a Complementary Stepper output. This will allow testing 2 tubes simultaneously in Push-Pull configuration. A DC current probe can then subtract the plate currents for display on a separate scope display. (An OT gets added for connecting the two plates to the swept Plate/Collector test terminal.) This will provide a graphic display of the resultant P-P summed currents usually shown in text books with a flipped around set of plate curves and regular plate curves offset by biasing. Biasing, Screen V, and Plate V can then be optimized for best P-P operation.

But until then, its already working as a good 2nd tube curve tracer. Here is the JJ KT77 tube, curve traced using the 10X Grid Step Module on the second 576:

Very nice curves. Look how evenly spaced. You won't be seeing any significant 3rd harmonic in a P-P amplifier with these tubes.

Last edited:

Ummm, well -35 dB at 200Vp-p is 0.03%, would likely beat many tube driver stages. Must be running out of Gain-BW at 200Vp-p though.

50Vp-p drive at -70 dB is looking good. At least up to 10 KHz.

-70dB and 3 KHz is more than fine for curve tracing.

I actually leave a little biasing squiggle in the modded step amplifier, so I can tell when zero grid Volts is being crossed when adjusting the continuous Offset dial.

50Vp-p drive at -70 dB is looking good. At least up to 10 KHz.

-70dB and 3 KHz is more than fine for curve tracing.

I actually leave a little biasing squiggle in the modded step amplifier, so I can tell when zero grid Volts is being crossed when adjusting the continuous Offset dial.

Good morning everyone,

apparently the JJ EL509 is the one "sweep" beam power tube currently manufactured, in front of those magnificent NOS television tubes which are becoming hard to find. Has anybody ever made experimental comparison between the JJ EL509 and the NOS EL509/6KG6?

apparently the JJ EL509 is the one "sweep" beam power tube currently manufactured, in front of those magnificent NOS television tubes which are becoming hard to find. Has anybody ever made experimental comparison between the JJ EL509 and the NOS EL509/6KG6?

Probably a radical suggestion but you could use a few HV supplies, pencil & graph paper. Yes it takes quite a bit of time but the thing with curve tracers & valve testers is they tend to just sit there doing nothing for months on end. All Tek 500 scopes & CT's are massive, weigh a ton, take up a lot space and need constant fixing. If you are thinking of buying a 576 or similar forget shipping unless it is done by a specialist shipping firm, the CRT's are very easily damaged and rare as rocking horse earwax.

Andy.

Andy.

Way to go! Or you could ditch the pencil and paper and use pypsucurvetrace instead 😎Probably a radical suggestion but you could use a few HV supplies, pencil & graph paper.

You don't need a curve tracer for this. Just look at the published curves.

https://www.jj-electronic.com/images/stories/product/power_tubes/pdf/el509s.pdf

The JJ 160 Vg2 curves look better than the Amperex.

https://frank.pocnet.net/sheets/084/6/6KG6.pdf

Vg2 190V looks best.

Well, they look like a typical Sweep tube. Actual tube curves usually don't look that close to the published curves anyway, however. So a curve tracer is quite helpful.

Where is support for Xantrex XHR600 and XT250 programmable power supplies for that pypsucurvetrace? I already have these power supplies.

I use the Xantrex XT250 supplies with the Tek576 for screen voltages.

For a really clean Sweep tube, check these 21LG6A curves with very low screen current. Nobody uses these hardly, dirt cheap and no euphonic distortion to croon over.

https://frank.pocnet.net/sheets/123/6/6LG6.pdf

https://www.jj-electronic.com/images/stories/product/power_tubes/pdf/el509s.pdf

The JJ 160 Vg2 curves look better than the Amperex.

https://frank.pocnet.net/sheets/084/6/6KG6.pdf

Vg2 190V looks best.

Well, they look like a typical Sweep tube. Actual tube curves usually don't look that close to the published curves anyway, however. So a curve tracer is quite helpful.

Where is support for Xantrex XHR600 and XT250 programmable power supplies for that pypsucurvetrace? I already have these power supplies.

I use the Xantrex XT250 supplies with the Tek576 for screen voltages.

For a really clean Sweep tube, check these 21LG6A curves with very low screen current. Nobody uses these hardly, dirt cheap and no euphonic distortion to croon over.

https://frank.pocnet.net/sheets/123/6/6LG6.pdf

Last edited:

Do you have the documentation for the command interface? If so, please send a copy to me (by PM) so I can check if it's worth to add support for these PSU devices to pypsucurvetrace.Where is support for Xantrex XHR600 and XT250 programmable power supplies for that pypsucurvetrace? I already have these power supplies.

Xantrex, Sorensen, Ametek XHR or XT supply programmable interfaces. The same remote option board can be configured for either type (GPIB or RS-232 ) interface with an Eprom and interface chip change. I have mine set up for RS-232 currently.

RS-232 interfaces and GPIB interfaces. Similar command structure.

RS-232

https://xdevs.com/doc/Xantrex/XT/TM-RS6H-01XN.pdf

https://www.manualslib.com/download/195446/Xantrex-Rs232-Xhr.html

GPIB

https://xdevs.com/doc/SORENSEN/Sorensen HPD-XTS_ M9(GPIB)_Manual_TM-9BGP-6HSN_Rev2_1.pdf

https://xdevs.com/doc/Xantrex/XFR/TM-GPRF-01XN.pdf

For tube curve tracing, the XHR600 gives you 0-600V for plate voltage.

XT250 gives you 0-250V for screen voltage. Alternative XHR300 0-300V

XT60 or XT120 for grid 1 steps. 0-60V or 0-120V

The XHR supplies have gotten pricey on EBAY, I got mine back during the DOT.com crash. $300 working, $50 fix-r-up

XHR is obsolete now. The newer versions most likely continue the same interface protocall for compatibility. XHR is a 1000 Watt switching bench supply.

XT supplies are 60 Watt linear bench supplies.

The D/A and A/D resolution is 12 bit, but only 10 bit monotonicity guaranteed with the chips supplied.

A software interface between pypsucurvetrace and Spice (as a tube model) could be an interesting extension. Use the real tube in your Spice modeling.

RS-232 interfaces and GPIB interfaces. Similar command structure.

RS-232

https://xdevs.com/doc/Xantrex/XT/TM-RS6H-01XN.pdf

https://www.manualslib.com/download/195446/Xantrex-Rs232-Xhr.html

GPIB

https://xdevs.com/doc/SORENSEN/Sorensen HPD-XTS_ M9(GPIB)_Manual_TM-9BGP-6HSN_Rev2_1.pdf

https://xdevs.com/doc/Xantrex/XFR/TM-GPRF-01XN.pdf

For tube curve tracing, the XHR600 gives you 0-600V for plate voltage.

XT250 gives you 0-250V for screen voltage. Alternative XHR300 0-300V

XT60 or XT120 for grid 1 steps. 0-60V or 0-120V

The XHR supplies have gotten pricey on EBAY, I got mine back during the DOT.com crash. $300 working, $50 fix-r-up

XHR is obsolete now. The newer versions most likely continue the same interface protocall for compatibility. XHR is a 1000 Watt switching bench supply.

XT supplies are 60 Watt linear bench supplies.

The D/A and A/D resolution is 12 bit, but only 10 bit monotonicity guaranteed with the chips supplied.

A software interface between pypsucurvetrace and Spice (as a tube model) could be an interesting extension. Use the real tube in your Spice modeling.

Last edited:

Oh yeah, I also use Xantrex HPD 60-5 supplies for the heater voltages ( 300 Watt, 0-60V, 0-5 Amp, bench switcher with linear post regulator, looks like the XT supplies ). I think it uses the same option board for interfacing as the XT supplies.

Last edited:

Looking at the manuals, it should be straight forward to add support for these units in pypsucurvetrace. Would you be willing to borrow your unit for a couple of weeks to get this done?Xantrex, Sorensen, Ametek XHR or XT supply programmable interfaces. The same remote option board can be configured for either type (GPIB or RS-232 ) interface with an Eprom and interface chip change. I have mine set up for RS-232 currently.

RS-232 interfaces and GPIB interfaces. Similar command structure.

Not sure what you mean by this. I am very clueless when it comes to SPICE, so... can you explain?A software interface between pypsucurvetrace and Spice (as a tube model) could be an interesting extension. Use the real tube in your Spice modeling.

Sure, I can loan out a supply for testing. But where does it need to be shipped? The power supplies are somewhat heavy. 11 or 12 Lbs.

Spice:

Spice normally has software models for the electrical devices it uses in the simulation. Like a model for a specific tube. The extension idea would have Pypsucurvetrace callable as a tube model by the Spice simulator, while running an amplifier simulation. Pypsucurvetrace would take the terminal voltages for the tube (V parameters sent by Spice), run a single point trace of the tube, and return the tube currents (plate and any screen current) back to Spice. Spice would be repeatedly calling Pypsucurvetrace during the simulation run as the simulation signal levels change (1000s of times). This would obviously be a little slower than using a software tube model, RS-232 or GPIB communication times plus power supply V settling times for each call. But you would be getting a real result with actual distortion expected. Some Spice programs can save the results, to be played back on the computer soundcard. Just a fun idea.

Spice:

Spice normally has software models for the electrical devices it uses in the simulation. Like a model for a specific tube. The extension idea would have Pypsucurvetrace callable as a tube model by the Spice simulator, while running an amplifier simulation. Pypsucurvetrace would take the terminal voltages for the tube (V parameters sent by Spice), run a single point trace of the tube, and return the tube currents (plate and any screen current) back to Spice. Spice would be repeatedly calling Pypsucurvetrace during the simulation run as the simulation signal levels change (1000s of times). This would obviously be a little slower than using a software tube model, RS-232 or GPIB communication times plus power supply V settling times for each call. But you would be getting a real result with actual distortion expected. Some Spice programs can save the results, to be played back on the computer soundcard. Just a fun idea.

One could also just do a standard curve trace for a selected tube, with the results saved as a lookup table. That table would be used by a software tube model for Spice, with math interpolation between the measured points to fit the Spice calling parameters. That would allow greater simulation speed, and more than one tube type could be available. Five dimensional data tables can get pretty big though. Vp, Vg2, Vg1, Ip, Ig2

Maybe can do curve fitting between measured points (instead of straight line fitting) to reduce the table size (reduced density).

Maybe can do curve fitting between measured points (instead of straight line fitting) to reduce the table size (reduced density).

Last edited:

I am in Switzerland.Sure, I can loan out a supply for testing. But where does it need to be shipped? The power supplies are somewhat heavy. 11 or 12 Lbs.

Getting a good reading from a programmable PSU is slooooow. Getting thousands of readings for SPICE would take extremely long. It would be better to interpolate from measured curve sets. I don't know if/how SPICE does that, but it would certainly be possible to do this from pypsu data files.Spice:

Spice normally has software models for the electrical devices it uses in the simulation. Like a model for a specific tube. The extension idea would have Pypsucurvetrace callable as a tube model by the Spice simulator, while running an amplifier simulation. Pypsucurvetrace would take the terminal voltages for the tube (V parameters sent by Spice), run a single point trace of the tube, and return the tube currents (plate and any screen current) back to Spice. Spice would be repeatedly calling Pypsucurvetrace during the simulation run as the simulation signal levels change (1000s of times). This would obviously be a little slower than using a software tube model, RS-232 or GPIB communication times plus power supply V settling times for each call.

The US Postal Service Flat Rate box for Intl. shipping is $118 and it is not long enough or high enough. Need about 15" length by 7" for the XT supply and 19" by 10" for the XHR supply (allowing for packing matl. ). I ordered an XHR from Singapore once, and the shipping was more than the supply cost.

If I could find an XT supply already in Europe on Ebay.... Here's one in NJ, US for $60 with GPIB:

https://www.ebay.com/itm/266244400594

But most of them are more like $300 and hard to find with an RS-232 interface. Probably take years to find the right one in Europe on Ebay.

I've run the RS-232 models using a Terminal emulation program here to check them out before. The hardest part was getting the dumb RS-232 stuff to match up.

How about me testing your interface software here? Maybe just need a simplified test program to do a sawtooth wave or something, with a voltage readback plotted on the computer screen. Post any error codes on screen too, and a keyboard entry for sending an ASCII string to the supply to clear any error status. I can do any further tests you want verified. I think there are some Vmax and Imax commands for example. But the XHR switching supply will be slow to limit current with its big filter cap. ( I think it does have a pull-down trans. to speed that up at least. )

Can even test the whole shebang on tubes and compare the results with the Tek 576.

Oh, wait. I'm using a Windows 7 notebook now. I guess one can get a USB to RS-232 adapter. But that will probably impact your interface code. Workable?

If I could find an XT supply already in Europe on Ebay.... Here's one in NJ, US for $60 with GPIB:

https://www.ebay.com/itm/266244400594

But most of them are more like $300 and hard to find with an RS-232 interface. Probably take years to find the right one in Europe on Ebay.

I've run the RS-232 models using a Terminal emulation program here to check them out before. The hardest part was getting the dumb RS-232 stuff to match up.

How about me testing your interface software here? Maybe just need a simplified test program to do a sawtooth wave or something, with a voltage readback plotted on the computer screen. Post any error codes on screen too, and a keyboard entry for sending an ASCII string to the supply to clear any error status. I can do any further tests you want verified. I think there are some Vmax and Imax commands for example. But the XHR switching supply will be slow to limit current with its big filter cap. ( I think it does have a pull-down trans. to speed that up at least. )

Can even test the whole shebang on tubes and compare the results with the Tek 576.

Oh, wait. I'm using a Windows 7 notebook now. I guess one can get a USB to RS-232 adapter. But that will probably impact your interface code. Workable?

Last edited:

- Home

- Amplifiers

- Tubes / Valves

- Curve tracer suggestions