Greetings to all,

first thing first, I have very basic knowledge in crossover build so please be kind.🙄

A couple of years ago I bought a pair of KEF Q950 speakers really cheap. Now I want to upgrade their crossover parts to better ones to see if I will gain any sonic benefit. The reason for doing this is that the crossover is rather simple and uses very little part count, hence small fundings needed and not that complicated to be done from me.

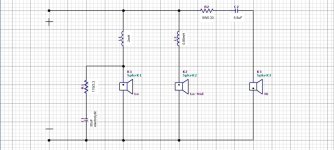

The schematic and a picture of the crossover is in the attachment.

I did a little research of my own about sound signatures of different components. Taking into account on how the sound can change and what sonic difference I'm after, I have already bought the capacitors (30uF Jantzen CrossCap/ 5.6uF Jantzen Superior-Z), resistors (Mundorf MOX 10W), Jantzen brass binding posts.

I'm very sensitive to harsh treble so that is the main aspect that I am trying to avoid. Also I would appreciate some additional juiciness in the midrange and guitars / piano.

Now comes my concerns about the rest of the parts and where I need the most help.

For the inductors I can't measure the DCR for now(just ordered some LCR meter from china). But if we hypothetically say that they are equal in DCR:

1. If I change the coil for the low frequencies from the stock ferrite core inductor 2.0mH/DCR?/ AWG ? to an air core Mundorf 2.0mH/0.45ohm/18AWG how will this affect the sound? Will it be worth the effort?

2. If I change the coil for the low midrange from the stock ferrite core inductor 0.85mH/ DCR?/ AWG ? to an air core Jantzen 0.85mH/0.45ohm/18AWG how will this affect the sound? Will it be worth the effort?

Any advice will be appreciated!

first thing first, I have very basic knowledge in crossover build so please be kind.🙄

A couple of years ago I bought a pair of KEF Q950 speakers really cheap. Now I want to upgrade their crossover parts to better ones to see if I will gain any sonic benefit. The reason for doing this is that the crossover is rather simple and uses very little part count, hence small fundings needed and not that complicated to be done from me.

The schematic and a picture of the crossover is in the attachment.

I did a little research of my own about sound signatures of different components. Taking into account on how the sound can change and what sonic difference I'm after, I have already bought the capacitors (30uF Jantzen CrossCap/ 5.6uF Jantzen Superior-Z), resistors (Mundorf MOX 10W), Jantzen brass binding posts.

I'm very sensitive to harsh treble so that is the main aspect that I am trying to avoid. Also I would appreciate some additional juiciness in the midrange and guitars / piano.

Now comes my concerns about the rest of the parts and where I need the most help.

For the inductors I can't measure the DCR for now(just ordered some LCR meter from china). But if we hypothetically say that they are equal in DCR:

1. If I change the coil for the low frequencies from the stock ferrite core inductor 2.0mH/DCR?/ AWG ? to an air core Mundorf 2.0mH/0.45ohm/18AWG how will this affect the sound? Will it be worth the effort?

2. If I change the coil for the low midrange from the stock ferrite core inductor 0.85mH/ DCR?/ AWG ? to an air core Jantzen 0.85mH/0.45ohm/18AWG how will this affect the sound? Will it be worth the effort?

Any advice will be appreciated!

Attachments

Welcome to the forum!

Such a simple crossover provides an ideal platform on which to experiment!

It has to be noted that changing the types of capacitors and inductors will change the sound signature from that originally engineered by KEF - perhaps for the better, perhaps for the worse. Unless you have access to measuring equioment, you will have to rely on your ears in order to make that judgement.

1. An inexpensive 2.0 mH ferrite core inductor (AWG 21) could have a DCR of around 0.85 ohm compared to your 0.45 ohm air core.

2. An inexpensive 0.85 mH ferrite core inductor (AWG 21) could have a DCR of around 0.45 ohm compared to your 0.45 ohm air core.

The smaller DCR in relation to K1 using the air core is probably tolerable, and you will avoid the magnetic saturation of a ferrite core.

Such a simple crossover provides an ideal platform on which to experiment!

It has to be noted that changing the types of capacitors and inductors will change the sound signature from that originally engineered by KEF - perhaps for the better, perhaps for the worse. Unless you have access to measuring equioment, you will have to rely on your ears in order to make that judgement.

1. An inexpensive 2.0 mH ferrite core inductor (AWG 21) could have a DCR of around 0.85 ohm compared to your 0.45 ohm air core.

2. An inexpensive 0.85 mH ferrite core inductor (AWG 21) could have a DCR of around 0.45 ohm compared to your 0.45 ohm air core.

The smaller DCR in relation to K1 using the air core is probably tolerable, and you will avoid the magnetic saturation of a ferrite core.

Dear Galu, your best bet would be to put the crossover out of the enclosure. Haven't you seen me writing about it so obsessively? There must be a reason or it might be just for fun, I'd ask myself.

So my suggestion is: make a hole in the back of the UniQ driver chamber, and make the four wires pass trough it. Same for the woofer, you can use the same binding posts, but for 'purity' ( contacts, contacts) I'd just make the wire exit fron a hole, or two holes ( one each).

That's it.

Once you have your wires out of the box, the best thing is to consider each path referred at amplifier's output, so bi-tri-wiring is the thing.

So my suggestion is: make a hole in the back of the UniQ driver chamber, and make the four wires pass trough it. Same for the woofer, you can use the same binding posts, but for 'purity' ( contacts, contacts) I'd just make the wire exit fron a hole, or two holes ( one each).

That's it.

Once you have your wires out of the box, the best thing is to consider each path referred at amplifier's output, so bi-tri-wiring is the thing.

I've done this sort of mod many times, and don't recall it ever not being notably better (subjectively). Clients have always been happy with that mod too. The difference in DC resistance should be negligible (likely < 0.5db), but you could always experiment with adding a good, wire wound resistor in series with the tweeter if you think there's need.

Speaking of resistors, I'd also replace the sand cast resistors with good wire wound resistors of the same wattage and resistance values. If the wire is junk, you might consider replacing that while you're at it.

Depending on how the speakers were done originally, occasionally I'll even add a small amount of polyfil to help reduce internal resonance.

Speaking of resistors, I'd also replace the sand cast resistors with good wire wound resistors of the same wattage and resistance values. If the wire is junk, you might consider replacing that while you're at it.

Depending on how the speakers were done originally, occasionally I'll even add a small amount of polyfil to help reduce internal resonance.

There is nothing to gain simply swapping same-value components, so what you want to do is a waste of time and money. (*)Now I want to upgrade their crossover parts to better ones to see if I will gain any sonic benefit.

Cored coils aren't the devil, for sure they saturate, but a well engineered speaker should have cored coils that don't saturate with the voltage involved in real use.

Now if you still want to replace the cored coils with air ones, you need a multimeter that can reliably read the small resistance of the current coils in order to order a similar DCR air core coil. But be aware that the difference in size and weight will be significant.

(*) A complete redesign of a simple crossover can, in some cases, resolve some issues derived from too many compromise accepted for using such simple crossover. I'm not saying this is the case, but it could be. But this is a task for very skilled people with measurement gear.

Ralf

There is a thread somewhere with some data on the Q100 driver(s) and some improvements to the very simple XO. Maybe similar enough to give some ideas where to aim.First order on these coaxials does seem a cost cutting exercise.

Some inspiration on tweaking KEF Uni-Q speakers. The factory crossovers really are dead simple, which is remarkable in itself. KEF learnt long ago that every part left out means profit. But arguably a more elaborated crossover could bring real performance gain, not the kind that just swapping parts would bring. As said, you need gear and experience to bring such ’tweaks‘ to a good end.

Thanks! I've been around but only reading.Welcome to the forum!

I thought that the new inductors would be in the tollerable range so I suggested them......

Holes on the box are a no go! If it was ported design it would be the first to do but ..... Also the coaxial driver is in separate closed enclosure.

If the differences in DC resistance are so negligible I can try it. I did buy the one from Jantzen 0.85mH L2 for K2. I guess for K1 it won't be so audible?I've done this sort of mod many times, and don't recall it ever not being notably better (subjectively). Clients have always been happy with that mod too. The difference in DC resistance should be negligible (likely < 0.5db), but you could always experiment with adding a good, wire wound resistor in series with the tweeter if you think there's need.

Speaking of resistors, I'd also replace the sand cast resistors with good wire wound resistors of the same wattage and resistance values. If the wire is junk, you might consider replacing that while you're at it.

Depending on how the speakers were done originally, occasionally I'll even add a small amount of polyfil to help reduce internal resonance.

As for the resistors .....I wanted to get the Mundorf M-Resist SUPREME but there were no 0.33ohms at the shop I ordered. So I will settle for MOX ones.

The internal wiring is junk! But it is too much work to be changed. Also I want to hear what will change after the upgrade.

Ralf, redesign is out of the questione. I do not have the conditions, tools and the knowledge to do so ...... as i have said, only an amateur here.(*) A complete redesign of a simple crossover can, in some cases, resolve some issues derived from too many compromise accepted for using such simple crossover. I'm not saying this is the case, but it could be. But this is a task for very skilled people with measurement gear.

Ralf

Q1** series are similar I think. It would be nice to cut the coaxial midbass to a point I guess.... And thanks for the thread!There is a thread somewhere with some data on the Q100 driver(s) and some improvements to the very simple XO. Maybe similar enough to give some ideas where to aim.First order on these coaxials does seem a cost cutting exercise.

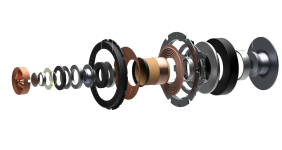

The tweeter

The reason KEF can use a simple series inductor filter for the lo-mid is that they have engineered a mechanical low pass filter into its design.

Here is the relevant quote from KEF regarding the UniQ technology:

"A resilient high damping link was used to connect the cone and the voice coil, so that only signal that’s within the waveband of the driver is transferred to the cone."

The resultant fitering action is therefore a combination of electrical (the inductor) and mechanical (the damping link or decoupler).

The decoupler between the lo-mid cone and voice coil assembly can be seen in the attachment.

Oh, and members have confirmed to me that the tweeter performs well with just the series capacitor, an opinion strengthened in one of the above links.

What I would suggest is that you convert only one crossover at first in order to compare it with the original to determine if your component upgrades really do make a difference.

Enjoy the loudspeaker diy and its associated learning curve!

It would be nice to cut the coaxial midbass to a point I guess....

The reason KEF can use a simple series inductor filter for the lo-mid is that they have engineered a mechanical low pass filter into its design.

Here is the relevant quote from KEF regarding the UniQ technology:

"A resilient high damping link was used to connect the cone and the voice coil, so that only signal that’s within the waveband of the driver is transferred to the cone."

The resultant fitering action is therefore a combination of electrical (the inductor) and mechanical (the damping link or decoupler).

The decoupler between the lo-mid cone and voice coil assembly can be seen in the attachment.

Oh, and members have confirmed to me that the tweeter performs well with just the series capacitor, an opinion strengthened in one of the above links.

What I would suggest is that you convert only one crossover at first in order to compare it with the original to determine if your component upgrades really do make a difference.

Enjoy the loudspeaker diy and its associated learning curve!

Attachments

I would put 3 woofers instead of One, and eliminate the box(es)Holes on the box are a no go!

Just.jocking!

What about those new Dayton line which are 30$, I believe, and so on...

What about a tri-path external crossover?!

Or eliminate me ..... no me, no crossover problems 🙄😆

I do the crossover upgrade for fun and if it has some positives it would be nice. For now the parts are worth about 94 euro or 105$ (except the inductor for the low frequencies but with the new binding posts).

I almost forgot......on one of the speakers I've connected a CORNELL DUBILIER 940C 3000V 0,01µ for the C1 and C2. From the beginning it wasn't so obvious but after a while it does sound a little bit more open and clear, bass is more as a quantity and so feeling it a little more. I'm expecting a bigger improvement with Superior-Z and CrossCap. Hope that Mundorf MOX does not do any harm as I've read on the forums that it gives some details but it can sound a little harsh.....

So my main question - am I going to clearly hear the difference if I upgrade the inductor for the 2 speakers?

As I understand it is connected on the +(sound path) so it has to be clearly audible? And what can I expect as a sound result? Did someone tested ?

I'm aware of that but if this low pass is mechanical, is it going to change with time as the material gets older and changes properties?The reason KEF can use a simple series inductor filter for the lo-mid is that they have engineered a mechanical low pass filter into its design.

Enjoy the loudspeaker diy and its associated learning curve!

I do the crossover upgrade for fun and if it has some positives it would be nice. For now the parts are worth about 94 euro or 105$ (except the inductor for the low frequencies but with the new binding posts).

I almost forgot......on one of the speakers I've connected a CORNELL DUBILIER 940C 3000V 0,01µ for the C1 and C2. From the beginning it wasn't so obvious but after a while it does sound a little bit more open and clear, bass is more as a quantity and so feeling it a little more. I'm expecting a bigger improvement with Superior-Z and CrossCap. Hope that Mundorf MOX does not do any harm as I've read on the forums that it gives some details but it can sound a little harsh.....

So my main question - am I going to clearly hear the difference if I upgrade the inductor for the 2 speakers?

As I understand it is connected on the +(sound path) so it has to be clearly audible? And what can I expect as a sound result? Did someone tested ?

I think if the DCR of the original and new inductor is remotely similar you will need very good ears/imagination to notice any difference.

Here's a story. At one stage in the early 90's I spent a couple of years as CTO of Wharfedale.

In an earlier existence I had developed a filter for the output of a class D amp for a supermarket security gate, and the inductors needed to be low loss at mid audio frequencies. The inductors needed to be multi-filar to minimize proximity effect. This is a technique that is well known to designers of switched mode power supplies, where winding losses have to be minimized, and switching transformers are wound with a combination of mulitfilar wire and ribbon conductors.

I suggested that we try this out with one of the higher end Wharfedale speakers. Same inductance values, same DC resistances - but much lower audio band loss.

They sounded really bad. Totally different mid range balance, hard and honky sounding.

Basically the original had been tuned to sound right with the non-ideal inductors.

So - upgrade resistors, and replace old and potentially sad non-polar electrolytic capacitors. But don't mess around "improving" the inductors. Leave them as-is.

In an earlier existence I had developed a filter for the output of a class D amp for a supermarket security gate, and the inductors needed to be low loss at mid audio frequencies. The inductors needed to be multi-filar to minimize proximity effect. This is a technique that is well known to designers of switched mode power supplies, where winding losses have to be minimized, and switching transformers are wound with a combination of mulitfilar wire and ribbon conductors.

I suggested that we try this out with one of the higher end Wharfedale speakers. Same inductance values, same DC resistances - but much lower audio band loss.

They sounded really bad. Totally different mid range balance, hard and honky sounding.

Basically the original had been tuned to sound right with the non-ideal inductors.

So - upgrade resistors, and replace old and potentially sad non-polar electrolytic capacitors. But don't mess around "improving" the inductors. Leave them as-is.

Actually, looking at the parts in the crossover photo, the parts that KEF have used are high quality anyway. Bennic is a well-known supplier of high quality crossover parts. Taiwanese sure, but very good parts https://www.bennic.com.tw/en/index.asp

So why mess around trying to improve on something that is already good?

So why mess around trying to improve on something that is already good?

which material are you talking about? Plastic, fabric, glue, metal, paper or...? The properties of each has been selected and engineered by the manufacturer. Or maybe you mean the physical dimensions that often dictate the kind of emission, so diameter of the cone, mass, geometry of the cone ?I'm aware of that but if this low pass is mechanical, is it going to change with time as the material gets older and changes properties?

Anyway, good luck

The capacitor on the tweeter is just ok. At least not electrolytic but that doesn't mean it's great. Upping the part quality won't break the bank because of the low values of the components in this specific case. I did get one for 19 euro with education/experience purposes. I could get by with a lower cost one but what the hell .... Resistors are standard sand cast ones, I don't know if there will be an improvement but the 2 resistors are worth 4euro .... Coils are the most questionable for me because they take space, have to be positioned in a specific way and a bigger gauge will cost higher.Actually, looking at the parts in the crossover photo, the parts that KEF have used are high quality anyway. Bennic is a well-known supplier of high quality crossover parts. Taiwanese sure, but very good parts https://www.bennic.com.tw/en/index.asp

So why mess around trying to improve on something that is already good?

Most of the speakers cost about 10k euro with the cheapest parts quality which is so odd. Good quality ones are not that pricier. Sadly the manufacturer's are cutting costs, but I see it as luckily for us that we can upgrade it later.

@picowallspeaker

"Plastic, fabric, glue, metal, paper" yes I guess or whatever they use in it. Not that low cost electrolytic capacitors has low precicion or do not change properties with time but ..... Maybe tradeoff's.

So generally I'm on a right track. Inductor are still questionabe.....

- Home

- Loudspeakers

- Multi-Way

- Crossover upgrade advice needed