Hi,

I'm starting a project from Parts-Express called "Sophomores". You can find the project here: “Sophomores” writeup.... - Techtalk Speaker Building, Audio, Video, and Electronics Customer Discussion Forum From Parts-Express.com

I already have the 2 HiVi M4Ns and I will start ordering the rest of the parts very soon. There seems to be a lot of controversy on using x-parts in crossovers and how it affects sound etc.

For the resistors. Can I use a standard wire-wound? (Not "audio-grade"?) Something like this: 280-CR25-7.5-RC Xicon Wirewound Resistors - Through Hole

Just out of curiosity...What would happen if I used some 50W thick film resistors instead of the wirewounds?

Secondly. As far as capacitors go, how much better do poly-film capacitors sound in comparison to non-polarized electrolytics (NPEs). Films start to get reaaaally expensive...and I'm trying to be as economical as possible.

I appreciate any input. After doing some preliminary planning for the crossovers, the xovers wind up being almost 1/3 of the cost of the entire project...and that sure says something. So I'd like to make some cost cuts...

Thanks.

Yours truly

I'm starting a project from Parts-Express called "Sophomores". You can find the project here: “Sophomores” writeup.... - Techtalk Speaker Building, Audio, Video, and Electronics Customer Discussion Forum From Parts-Express.com

I already have the 2 HiVi M4Ns and I will start ordering the rest of the parts very soon. There seems to be a lot of controversy on using x-parts in crossovers and how it affects sound etc.

For the resistors. Can I use a standard wire-wound? (Not "audio-grade"?) Something like this: 280-CR25-7.5-RC Xicon Wirewound Resistors - Through Hole

Just out of curiosity...What would happen if I used some 50W thick film resistors instead of the wirewounds?

Secondly. As far as capacitors go, how much better do poly-film capacitors sound in comparison to non-polarized electrolytics (NPEs). Films start to get reaaaally expensive...and I'm trying to be as economical as possible.

I appreciate any input. After doing some preliminary planning for the crossovers, the xovers wind up being almost 1/3 of the cost of the entire project...and that sure says something. So I'd like to make some cost cuts...

Thanks.

Yours truly

re:'resistors. Can I use a standard wire-wound?' - as long as they are non-inductive; an alternative is to parallel several lower rated metal film resistors to get the value & power rating you want

re: poly-film capacitors in comparison to non-polarized electrolytics - electrolytics degrade over time (years), but big poly caps are expensive.... I use electrolytics for values over ~ 10uf

re: poly-film capacitors in comparison to non-polarized electrolytics - electrolytics degrade over time (years), but big poly caps are expensive.... I use electrolytics for values over ~ 10uf

Well... I had some old Advents a few years ago and these benefited greatly when I changed the crossover caps to Wondercaps (no longer made AFAIK)

As to resistors, I think non-inductive wire wound are a good choice for a crossover unless you have a way to monitor actual inductance of the assembly and can tailor the inductors accordingly. (generally you can't, so why risk adding some inductance from resistors?)

So, I guess the crossover will sound as good as you are willing to make it sound. You could always build them up and then change components later if cost is a huge concern for you now...

As to resistors, I think non-inductive wire wound are a good choice for a crossover unless you have a way to monitor actual inductance of the assembly and can tailor the inductors accordingly. (generally you can't, so why risk adding some inductance from resistors?)

So, I guess the crossover will sound as good as you are willing to make it sound. You could always build them up and then change components later if cost is a huge concern for you now...

Alright thanks everyone. This cost of this project just keeps on growing, and I'm trying to cut back a little bit. I'm no "audiophile" by any means, though I still want it to sound decent.

Hi,

~~~~~~~~~~~~~~~~Snip~~~~~~~~~~~

There seems to be a lot of controversy on using x-parts in crossovers and how it affects sound etc.

For the resistors. Can I use a standard wire-wound? (Not "audio-grade"?) Something like this: 280-CR25-7.5-RC Xicon Wirewound Resistors - Through Hole

Just out of curiosity...What would happen if I used some 50W thick film resistors instead of the wirewounds?

As others have already pointed out, just make sure they're non-inductive and you'll probably be OK.

Secondly. As far as capacitors go, how much better do poly-film capacitors sound in comparison to non-polarized electrolytics (NPEs). Films start to get reaaaally expensive...and I'm trying to be as economical as possible.

We've actually done listening tests and most people couldn't tell which of two identical pairs of speakers had electrolytic caps and which had poly caps. Just a note, all the caps in both pairs had small value poly (fairly cheap) bi-pass caps in parallel. Let your budget be your guide.

I appreciate any input. After doing some preliminary planning for the crossovers, the xovers wind up being almost 1/3 of the cost of the entire project...and that sure says something. So I'd like to make some cost cuts...

Thanks.

You're welcome and good luck on your project, it should sound very nice!

Best Regards,

TerryO

1/3 of the project cost for the crossover is not out of line. Especially with the cost of copper these days. Almost any of the budget items at Parts Express will serve you well.

Wirewound inductance in crossovers is not that important. Typical values between 2R and 22R are not going to shift much at 20KHz

The place where it matters is the ~0R2 emitter resistors in amplifier output stages, where the inductance causes stability problems

The place where it matters is the ~0R2 emitter resistors in amplifier output stages, where the inductance causes stability problems

Thanks again. I'll just get most of the items from Parts Express and the NPEs from Mouser.

Tomorrow, hopefully I will have everything sorted out and will make an order.

Thanks again.

Tomorrow, hopefully I will have everything sorted out and will make an order.

Thanks again.

Just a quick question which I'm pretty sure I know the answer to...but I just want to be certain of. If the X-Over schematic calls for a 6.45uF capacitor, using 6x 1uF films + 1x 0.47uF film would give me 6.47uF. 6.47 is close enough to 6.45 is it not? Capacitors have a pretty big tolerance anyway so a capacitor labeled 6.45uF can be +/- 5-10%?

Re the 6.45 I would simply buy a few 6.8s and measure them to find the closest. Too many caps in parallel is not to my taste, but that's just me. You can also look at a batch of 3.3uF and use two in parallel that give you the closest to 6.45.

I've seen instances of improvement in multi-thousand dollar speakers just by changing the series caps from unknown brand to better quality products - nothing exotic, just Jantzens. It may be worthwhile to look at specific bits of the crossover, and thereby keep a reasonable path between cost and performance.

Expensive parts are not always better, though sometimes the real cheap stuff can be nasty. Industrial parts, for some strange reason, seem to be almost always a bit better off with less variations between parts and between manufacturers. They are also a fair bit cheaper than some boutique products.

I've seen instances of improvement in multi-thousand dollar speakers just by changing the series caps from unknown brand to better quality products - nothing exotic, just Jantzens. It may be worthwhile to look at specific bits of the crossover, and thereby keep a reasonable path between cost and performance.

Expensive parts are not always better, though sometimes the real cheap stuff can be nasty. Industrial parts, for some strange reason, seem to be almost always a bit better off with less variations between parts and between manufacturers. They are also a fair bit cheaper than some boutique products.

With respect to cap tolerances the one place where it does seem to make a difference is in notch filters. small changes can make a quite a difference depending on the particular notch filter (based on sims I have done where the measured result of the final implementation correlated closely to the simulation).

If you aren't using any notch filters then it's probably not going to be an issue except perhaps if you have high qaulity matched tweeters where differences between the channels *might* affect the imaging (note that comment is speculative in nature and not based on actual experience).

Another good source of value polypropylene caps is partsconnexion, the axon caps seem to me to be excellent value, the ones I have purchased have measured within 1% of rated value and you can ask them to match them to a nominated value for a small additional fee 🙂

Tony.

If you aren't using any notch filters then it's probably not going to be an issue except perhaps if you have high qaulity matched tweeters where differences between the channels *might* affect the imaging (note that comment is speculative in nature and not based on actual experience).

Another good source of value polypropylene caps is partsconnexion, the axon caps seem to me to be excellent value, the ones I have purchased have measured within 1% of rated value and you can ask them to match them to a nominated value for a small additional fee 🙂

Tony.

Last edited:

Putting tolerances aside for the moment, here's my advice. Resistors, don't fret, just about anything will do. Caps, it's nice to replace elcos if you have the budget, but no need to go for ultra high cost "Audiophile" components, stock films are fine. Inductors, avoid ferrite core at all cost, air core is the way to go. You can buy, or if you have an LCR meter, make your own from spools of varnished copper wire. If you need a really high value inductor, for a sub for example, then rip it out and go active for that stage. 😉

Thanks to all who replied. I appreciate it.

I think I've narrowed down my budget decently. I will be using Panasonic ECWF film caps for the majority of the crossover. Picture:

I will need to buy 26 in order to get the values required, which actually helps me because if I buy 25+ on Mouser, I get each for a measly $0.81 USD.

I think they are decent caps and are still better than any NPEs. Regarding NPEs, I am going to be using Nichicon ES "audio grade" NPEs. Perhaps you have seen them before. The crossover schematic calls for a 21.44uF capacitor and a 22uF capacitor. Since these are so cheap, I think I will buy about 15 of them and see if I can get ideal values using my multimeter. They look like this:

I finally found a decent dual secondary toroidal transformer on Parts Express for $55. It seems expensive, but I suppose I can't do much better. It's a 30V 250VA transformer. Is that overkill?

My amp will be dual LM3886s and will be able to drive about 45W/channel.

I just thought I'd give an update. That's where I'm at. I'll report later.

I think I've narrowed down my budget decently. I will be using Panasonic ECWF film caps for the majority of the crossover. Picture:

An externally hosted image should be here but it was not working when we last tested it.

I will need to buy 26 in order to get the values required, which actually helps me because if I buy 25+ on Mouser, I get each for a measly $0.81 USD.

I think they are decent caps and are still better than any NPEs. Regarding NPEs, I am going to be using Nichicon ES "audio grade" NPEs. Perhaps you have seen them before. The crossover schematic calls for a 21.44uF capacitor and a 22uF capacitor. Since these are so cheap, I think I will buy about 15 of them and see if I can get ideal values using my multimeter. They look like this:

I finally found a decent dual secondary toroidal transformer on Parts Express for $55. It seems expensive, but I suppose I can't do much better. It's a 30V 250VA transformer. Is that overkill?

My amp will be dual LM3886s and will be able to drive about 45W/channel.

I just thought I'd give an update. That's where I'm at. I'll report later.

I have found the series capacitor in a tweeter circuit to be very sensitive to quality, and spend big bucks to get a good quality one (which one is I suppose open to huge debate). Other than that, I haven't found significant sonic effects from any of the other passive components. Tried low DCR expensive North Creek coils against your basic Parts Express air cores, and found no difference. This with essentially back to back comparisons of completed crossover assemblies.

Better to spend your money on a quality driver.

Better to spend your money on a quality driver.

1/3 of the project cost for the crossover is not out of line.

It sure as **** is out of line. Oh wait, you mean for smaller speakers. I forgot that some people like to build those. 🙂

Thanks for building a pair of my creations...

I can tell you what I used...

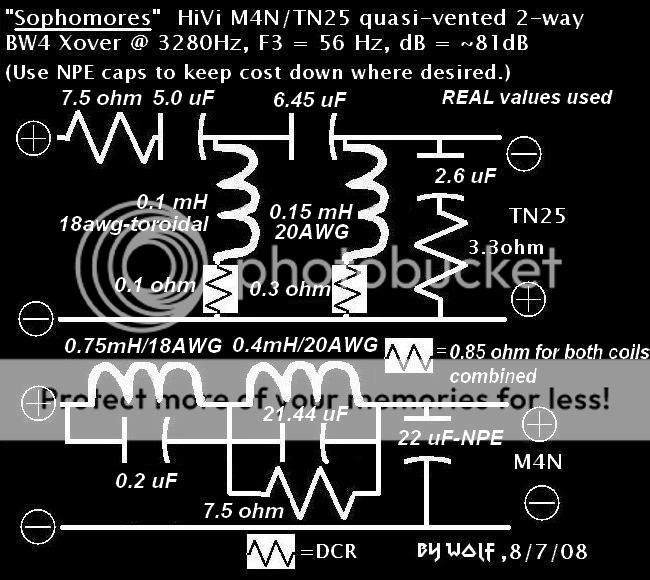

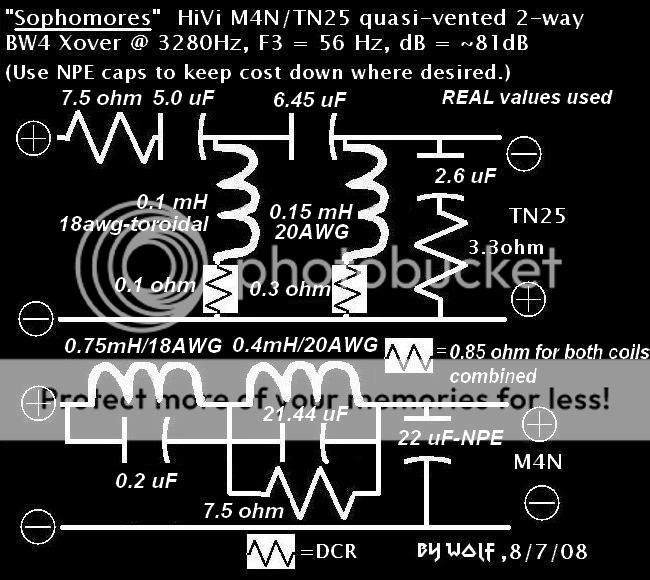

This is the schematic, and the parts as measured in the circuit, not what the standard value is:

Xover picture:

IMO- the 21.44uF (22uF) should be a poly. That is where most of the midrange information comes through, and vocals can be muffled if using an NPE in this range. I also recommend Jantzen CrossCaps for this part. I used an EFC (surplus) 400VDC poly 20uF cap that measured a little large.

In general, the caps should probably not exceed 0.5uF to guarantee the same sonic signature, so use what is closest. My recommendation would be to use Mylar caps from ERSE Audio for the tweeter and other places, but the '21.44' should be a poly.

I used the sandcast Xicon wirewound resistors on mine, so you should be fine there, and they're only 39c and 69c respectively for 5W and 10W.

The 'transformer' you found is not what you want. Just use a standard 0.1mH 20AWG air-core and be happy.

Sophomores pictures by wolf_teeth_speaker - Photobucket

Let me know if you have any other questions...

Later,

Wolf

Just a quick question which I'm pretty sure I know the answer to...but I just want to be certain of. If the X-Over schematic calls for a 6.45uF capacitor, using 6x 1uF films + 1x 0.47uF film would give me 6.47uF. 6.47 is close enough to 6.45 is it not? Capacitors have a pretty big tolerance anyway so a capacitor labeled 6.45uF can be +/- 5-10%?

I can tell you what I used...

This is the schematic, and the parts as measured in the circuit, not what the standard value is:

Xover picture:

IMO- the 21.44uF (22uF) should be a poly. That is where most of the midrange information comes through, and vocals can be muffled if using an NPE in this range. I also recommend Jantzen CrossCaps for this part. I used an EFC (surplus) 400VDC poly 20uF cap that measured a little large.

In general, the caps should probably not exceed 0.5uF to guarantee the same sonic signature, so use what is closest. My recommendation would be to use Mylar caps from ERSE Audio for the tweeter and other places, but the '21.44' should be a poly.

I used the sandcast Xicon wirewound resistors on mine, so you should be fine there, and they're only 39c and 69c respectively for 5W and 10W.

The 'transformer' you found is not what you want. Just use a standard 0.1mH 20AWG air-core and be happy.

Sophomores pictures by wolf_teeth_speaker - Photobucket

Let me know if you have any other questions...

Later,

Wolf

Last edited:

I can tell you what I used...

This is the schematic, and the parts as measured in the circuit, not what the standard value is:

Xover picture:

IMO- the 21.44uF (22uF) should be a poly. That is where most of the midrange information comes through, and vocals can be muffled if using an NPE in this range. I also recommend Jantzen CrossCaps for this part. I used an EFC (surplus) 400VDC poly 20uF cap that measured a little large.

In general, the caps should probably not exceed 0.5uF to guarantee the same sonic signature, so use what is closest. My recommendation would be to use Mylar caps from ERSE Audio for the tweeter and other places, but the '21.44' should be a poly.

I used the sandcast Xicon wirewound resistors on mine, so you should be fine there, and they're only 39c and 69c respectively for 5W and 10W.

The 'transformer' you found is not what you want. Just use a standard 0.1mH 20AWG air-core and be happy.

Sophomores pictures by wolf_teeth_speaker - Photobucket

Let me know if you have any other questions...

Later,

Wolf

Thanks Wolf!

22uF poly is brutally expensive but I see your point there.

I'm just confused as to how few components you have on your X-Over. That is: You don't seem to have many capacitors in parallel as I was planning on doing.

In general, the caps should probably not exceed 0.5uF to guarantee the same sonic signature, so use what is closest.

What do you mean here? The caps should not be more than 0.5uF off the value in the schematic?

Regarding the transformer. That was irrelevant. I was talking about my amplifier, not the coils on the crossover. I will be using the Air-Core coils from PE for the X-over.

Thanks.

Oh and one STUPID question. I've never built a set of speakers before so I don't know jack diddly about crossovers. I will need 1 tweeter X-over, and 1 M4N crossover PER CHANNEL, right? So a total of 4 crossovers?

Just wanted to make sure about that.

Thanks again.

"If you need a really high value inductor, for a sub for example, then rip it out and go active for that stage."

My advice is to investigate active for ALL of the crossover. Check eSpray for cheap stereo amps and "all" you then need is an active crossover. You may be surprised, PLUS, of course, you get the benefits of active.

Active Vs. Passive Crossovers

Frank

My advice is to investigate active for ALL of the crossover. Check eSpray for cheap stereo amps and "all" you then need is an active crossover. You may be surprised, PLUS, of course, you get the benefits of active.

Active Vs. Passive Crossovers

Frank

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Crossover Components: How much does it REALLY matter?